Now you really need a scanner. There are other brands and models, but I mentioned the Monitor 4000 because I have two of them and they are what I am familiar with. There is one on eBay right now. It is up to fifty six bucks plus shipping. Another one for about $105.00 including shipping, but I did not look to see what is included. Be sure you get a cartridge that covers the years and brands you need. Also be sure it comes with the long, odd-shaped Ford plug with the extra port for the fuel pump test plug.

I bought my first scanner because it came with a free cable and cartridge for Chrysler's computer-controlled transmissions, but I ended up never using it. The main cartridge will cover engine computers on GM's, Fords, and Chrysler's up to at least 1995 models if you get the right cartridge. If you only have, lets say a 1992 cartridge, for example, it will still do most functions on vehicles a year or two newer.

Today I have a Chrysler DRB3 scanner for all of my vehicles. When one of its optional add-on cards is plugged in, it will do emissions-related stuff on all brands of cars and light trucks sold in the U.S, but only on 1996 and newer models. The older version for 1995 and older vehicles was their DRB2 which is almost identical to the Monitor 4000 because the same company built both of them. Both use cartridges but they are not interchangeable between scanners. There was no commercially-available dealer-level scanner for Fords so you are stuck with aftermarket brands, but that can be a good thing because those will cover more brands.

Other than reading diagnostic fault codes, the function I use most often is called the "Automatic Test Mode", (ATM). This gives you a menu to pick the type of tests, then the specific function. In this case I would select "Ignition Coil". The scanner will command your engine computer to fire the ignition coil about once per second. If you find spark at a spark plug wire, you know the coil, the ignition module, the computer, and all the associated wiring are okay. When diagnosing a no-spark condition, you have just eliminated ninety percent of the system as a possible cause.

You can fire injectors the same way and turn the fuel pump and various relays on and off. You can do some of these things manually by bypassing relays, but that is a very time-consuming and inefficient way of doing these tests.

A really valuable test with my DRB3 that applies to your problem is viewing the state of the "Inputs/Outputs". There are over fifty things listed but the two that are relevant to a crank/no-start are the crankshaft position sensor and the camshaft position sensor. As I recall, your engine only has the camshaft position sensor, and it lives inside the distributor, but on newer engines, signals from both sensors are needed for the engine computer to turn on power to the ignition coil(s), injector(s), fuel pump, and other circuits. My scanner shows those two sensors as "No" or "Present" during cranking. The advantage of this is very often no fault code will set just from cranking the engine when one of those sensors has failed. They need more time for the missing signal to be detected, as when a stalled engine is coasting to a stop. Another way to look at this is if the engine stalled while you were driving at highway speed, it will have coasted for as much as five seconds before coming to a total stop. That is when the missing signal would be detected and a fault code would be set. Way too many people think they are going to fix a problem by erasing the fault code, and they do that by disconnecting the battery. Doing that erases any fault codes, then that valuable information is lost. Now, when you can only crank the non-running engine, the code will not set again. This is where the "No" or "Present" during cranking will show which signal is missing. I am sorry that I cannot remember if that feature existed on my Monitor 4000, but I think it is on the newer, more expensive scanners. I am bidding on some Snapon scanners on eBay to work on my 2014 truck. The most popular one is their "Solus Edge", but that is over the top for your needs. You would also have to buy an additional adapter plug for your truck.

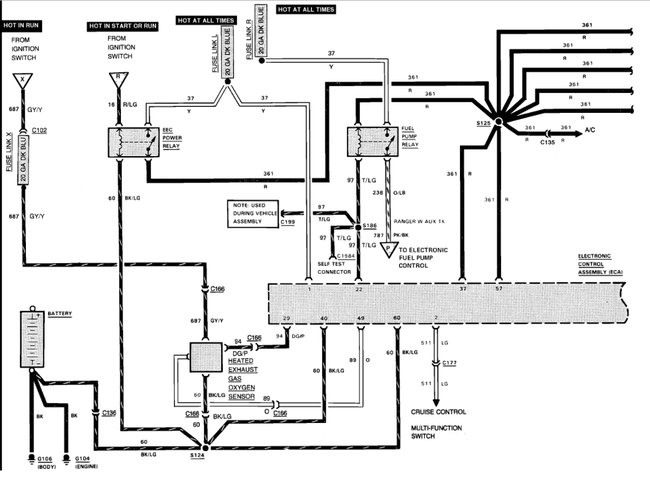

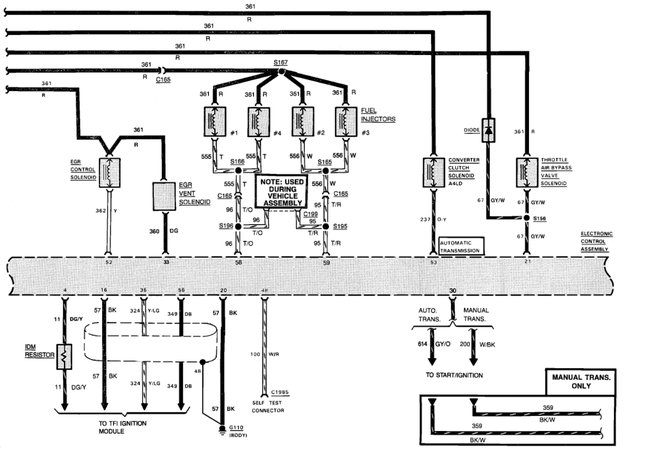

Again, I am doing this from memory, but if I remember correctly, the pick-up coil in the distributor develops a signal pulse that is fed to the ignition module on the side of the distributor. That module fires the ignition coil. That part of the system is very primitive and straight-forward, but the module and ignition coil aren't monitored, so you will not get a fault code related to their failures. The engine computer is inserted between the pick-up coil and module to modify spark timing, meaning how much delay there is before the module fires the ignition coil. It is the computer and its sensor circuits that are monitored and can have fault codes set. Most of that data has no affect on a crank/no-start problem.

The two biggest failure items were the ignition coil and the "TFI" module on the side of the distributor. I was taught at multiple classes that any time you have to replace the ignition coil, the module, or the pick-up coil, you should replace all three, but I cannot remember why. It is not because all the parts are the same age and are all expected to fail at the same time. It had something to do with voltage spikes or current surges caused by one item damaging the others, or something like that. To say that a different way, If you get the engine running by replacing the module, for example, do not panic if the ignition coil fails a week or two later.

Friday, April 27th, 2018 AT 3:33 PM