I think we're looking at two different things. A good, fully-charged battery is going to measure 12.6 volts. That's with the engine not running and everything is turned off. It is common to find one with a higher voltage, but that is a false, or inaccurate reading and is due to the battery was just removed from a charger. The resulting "surface charge" is due to an excess of electrons that haven't become stored in the plates yet. To get the accurate reading, turn on a load, such as the head lights, for about ten seconds. Turn the lights off, then measure the battery's voltage.

When a good battery is fully discharged, it will measure close to 12.2 volts. At that point it will not be able to deliver much current, certainly not enough to crank the engine. If you find its voltage is 11 volts or less, it has a shorted cell and must be replaced.

Regardless of its voltage, as batteries age, the lead gradually flakes off the plates and collects at the bottom of each cell. That leaves a lower and lower percentage left to store electrons. It will not be able to develop the current needed to run the starter. This will show up on a battery load test. The industry standard is it must be able to deliver half of its rated "cold cranking amps", (CCA), for 15 seconds, without its voltage dropping below 9.6 volts. It's still possible for a tired battery to deliver enough current to crank the engine because most batteries start out with current ratings three or four times that which starter motors draw.

This lead flaking relates to a battery's warranty, as you found out. The warranty has nothing to do with how much you paid for it. Every battery manufacturer knows how fast the lead flakes off the plates. They can't prevent that, but they want to provide the longest warranty possible to make their product more attractive than that of their competitors. When they know, for example, enough lead will flake off and build up in the bottom of the cells to short one of them, in just over three years, they will provide a warranty to cover the time period it should last before that happens. Five years is a common warranty period, and it's no coincidence that many of those batteries fail just a month or two short of that. To get the couple dollars credit, you have to buy another battery from the same company, so they get another sale. It's also why a lot of batteries fail just a few months past their warranty period. You can find batteries with longer warranties, but they won't last any longer. You pay more for those batteries because the manufacturer knows ahead of time they're going to have to return some of that as part of their "pro-rated" warranty.

With respect to alternators, they are physically incapable of developing more current than they're rated for, but more importantly, they will never develop more than exactly what the entire electrical system needs, plus what goes to keep the battery charged. Switching to an aftermarket 200-amp alternator doesn't get you more current than the original one delivered. It gets you the capacity to develop more current if it is needed. The only time any alternator will develop near its maximum rated current is during the brief full-load output current test. That puts a huge electrical load on the system to make the alternator work as hard as possible. The test lasts just long enough to get a reading, usually just one or two seconds, but that can be enough time to blow the fuse. Chrysler used to use a fuse link wire to protect the output circuit. The diameter, or gauge of that wire was selected at the factory based on the size of the alternator being installed. Fuse link wires act like slow-blow fuses. If an aftermarket alternator exceeded the current rating of the fuse wire during the full-load test, the wire would likely survive for those couple of seconds. Today most cars use large fuses that are bolted into the under-hood fuse box. Those will not hold up to the brief high current during that test. Your model still uses a fuse link wire, so there should be no problem performing the full load test as long as it done quickly.

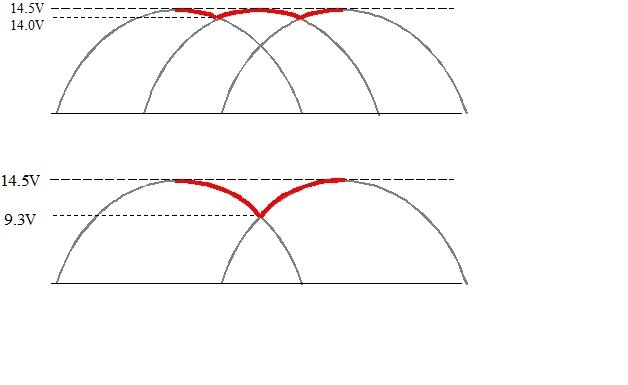

Previously, the discussion revolved around "ripple voltage". My drawing below shows what that looks like. A properly working alternator's output voltage looks like the top waveform. At any time, one of the three phases is developing its voltage, and therefore, current. Three-phase output is very stable and efficient. The red line shows the ripple voltage of 0.5 volts. That's the difference between the low and high points. It's very easy for the battery to smooth that out to roughly 14.3 volts.

In the lower waveform, one phase has been lost due to a failed diode. Here the ripple voltage is 5.2 volts. Remember, most professional testers will just show that as "high", not as an actual measured voltage. The changes in voltage aren't actually what causes problems because the battery is still there to supply some current when the alternator drops out. The problem is the drop in voltage, (pressure), is what causes a drop in current, (flow). When current flows through a wire, it sets up a magnetic field around that wire. Also, when a magnetic field surrounds another wire, it "induces" a voltage in that wire which again, causes current to flow in it. The pulsing current in the first wire creates a pulsing voltage in the second wire, and if that second wire is the signal wire for an engine sensor, it's very easy for a computer to perform the wrong calculations or produce incorrect outputs. One of those unusual reactions could be erratic idle speed.

Another concern has to do with how voltage regulators react to excessive ripple voltage. Some see the 14.5 volts as perfect, and try to maintain that, not realizing when it drops to 9.3 volts, current is also going to drop too low. The battery has to make up the difference as it slowly discharges over days or weeks. This is where the charging voltage appears to be fine, but under the full load output current test, the alternator can't develop more than one third of its rated capacity. You can do that voltage test yourself, but it's why that has to be followed up with the professional tests.

Some voltage regulators respond to the 9.3 volts and try to make the alternator work harder to get it back up to the acceptable range. Remember, an alternator can not develop more current than it is rated for, but it can develop a much higher output voltage. In this case, to get the low points up to at least 13.75 volts, the high points could exceed 18 to 20 volts. The average a voltmeter would show could be a perfect 13.75 to 14.75 volts, but 20 volts is reaching the point where computers can be damaged. The only thing that may prevent damage is the battery is trying to hold system voltage down.

This is a good place to point out a battery cable must never ever be disconnected while the engine is running. I did this every year on a test bench to show my students what can happen. Doing so, with a properly-working alternator run by a relatively weak drive motor could easily see output voltage exceed 35 volts. That WILL destroy computers and burn out any bulbs that are turned on. Years ago, uninformed people, and even mechanics, pulled a battery cable to see if the alternator was working, but that "test" doesn't prove anything. The engine could stall with a properly-working charging system, or a charging system with a major defect could keep an engine running, so there's no validity to that test. Today, a mechanic caught pulling that stunt will likely be fired.

To get back to your starting problem, have you made any progress, or is the problem acting up more often?

Image (Click to make bigger)

Thursday, April 4th, 2024 AT 3:03 PM