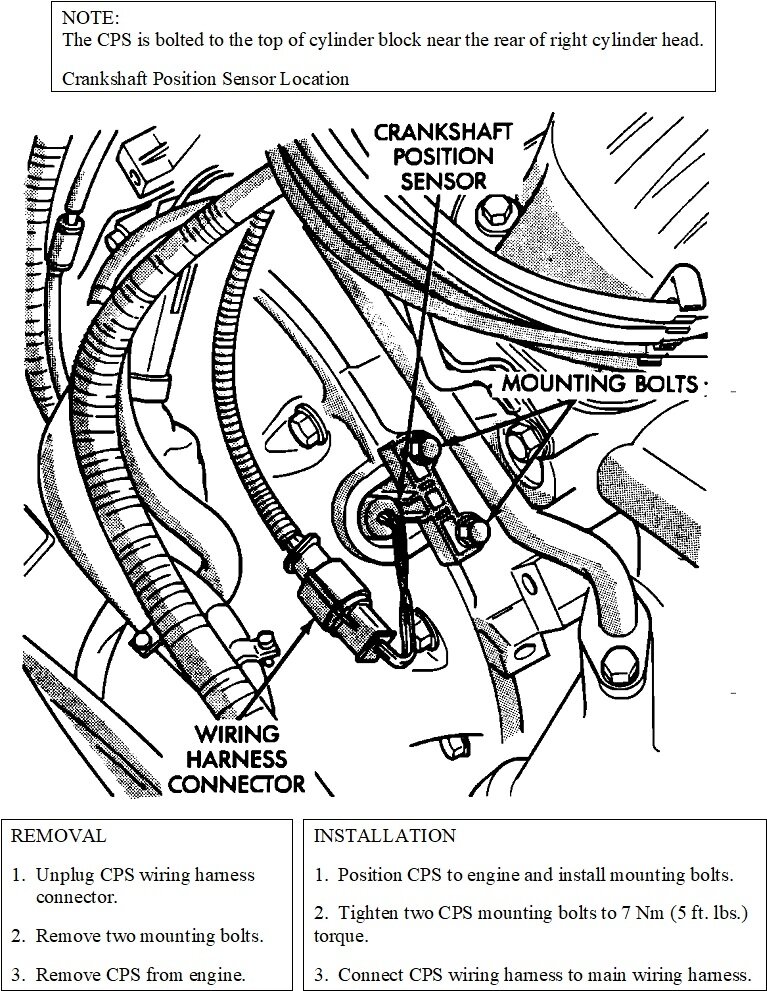

You're correct. The crankshaft position sensor sits in a hole in the bellhousing, right behind the right cylinder head, and must be removed before removing or installing the transmission. Some engines require a special paper spacer to set the critical air gap when reinstalling it, but on your truck, that depth is set by the design of the mounting bracket.

The clue to this is to measure the voltage at the ignition coil or any injector. Look for the wire that is the same color at every one of those items. That's usually a dark green / orange wire. Best is to use a test light as digital voltmeters take too long to respond. You should see the test light turn on full brightness for one second when a helper turns on the ignition switch, then it will go back off. You might be able to hear the hum of the fuel pump for that one second. That tells us the automatic shutdown, (ASD) relay is working and the Engine Computer has control of it.

What's important is the test light must turn back on during engine rotation, cranking or running. If it does not, it's almost always due to the crankshaft position sensor circuit or the camshaft position sensor circuit. The sensor itself will be the cause about half of the time. We also have to look for wiring and connector terminal problems, and mechanical problems associated with those sensors. In this case when we know the recent history, a broken crankshaft position sensor is the best suspect. I added the replacement instructions below.

Let me know how this turns out.

Image (Click to make bigger)

Sunday, May 28th, 2023 AT 5:52 PM