The second thing is most scanners have a "record" feature that lets you record a few seconds of data when a problem occurs, then you can play it back slowly, later, to see what changed. Because that data passes through the scanner's memory, the recording actually begins a couple of seconds before you pressed the switch. Things to look for here include a loss of signal from a crankshaft or camshaft position sensor, idle steps that went up as the car slowed down, but engine speed didn't respond, possibly indicating an air passage plugged with carbon, or something else cutting out when the problem occurred. Cam and crank sensors often fail too briefly to be detected and set a fault code.

The MAP sensor is another good sensor reading to look at. That measures intake manifold vacuum which is an indicator of load on the engine. If vacuum drops unexpectedly, suspect vacuum leaks, or less-commonly, a failing sensor.

All car brands except Chrysler use a mass air flow sensor too on most engines. Those measure the weight of the incoming air flow. With this sensor, it's critical that there's no leaks in the fresh air tube between that sensor and the throttle body. Loose hose clamps and cracks in the tube can cause intermittent problems when the engine rocks back and forth. Similar to a vacuum leak, that will show up as the air volume has gone down because some of it is sneaking into the engine without going through the sensor. When that air isn't included in the measurement, fuel to go with that unmeasured air doesn't get included in the fuel metering calculations, resulting in a lean condition, and probably stalling.

Sensor defects become less suspect when you can restart the engine right away, as you described. A different problem that only GM had in their early years of front-wheel-drive cars was a lock-up torque converter that got stuck and failed to unlock. That would be the same as if you had a manual transmission and failed to push the clutch pedal when the car was coming to a stop. This was so common that a lot of mechanics simply unplugged the electrical connector at the transmission so the lock-up feature never occurred, and therefore, it couldn't stick engaged. You'd loose two or three miles per gallon, but the stalling no longer occurred. When that did occur, the lock-up clutch released when the engine stalled, so it could be restarted right away. Whatever caused that problem has been addressed, because it hasn't been a problem for a long time.

Another elusive cause of stalling is a leaking EGR valve. Many engines don't have one, but when they do, they can't be allowed to open at idle and low speeds as it will cause stalling or misfires and a rough-running engine. Often this can be identified by disconnecting and plugging the vacuum hose at the valve assembly so it never opens. That could identify a valve that's sticking open intermittently. With the vacuum hose disconnected, the valve won't open at highway speed, so it can't get stuck.

It's more common for a chip of carbon to get caught in the valve and allow exhaust gas to keep flowing into the engine. You won't notice that at high speeds, but again, at low speeds is when the stalling or rough-running shows up. That chip of carbon is typically going to break free and go into the engine, and therefore it's a one-time thing, or it's going to be permanently stuck and the valve will remain partially-open all the time. Neither of these really fits what you're experiencing.

The last thing I can think of is a lot of people seem to solve intermittent problems on GM vehicles by cleaning or repairing ground wires for the Engine Computer. All Chrysler Engine Computers have four ground wires. Two are "signal" grounds and two are "power" grounds. Power grounds are for things that draw a lot of current in pulses, not steadily. That mainly includes injectors, ignition coils, and relays and solenoids. "Signal" grounds are for sensitive circuits such as most engine sensors. All wires have some resistance, and in the case of those high-current items, when that current pulses on, it results in dropping a small voltage across the resistance in the wire. That might be as much as maybe a tenth of a volt which would have absolutely no effect on those injectors and ignition coils, but to drop that tenth of a volt on a sensor's ground wire would have a major effect on how the computer interprets its readings. To prevent that interaction is why separate ground wires are used for sensors. Chrysler uses a redundant or second ground wire for each one, just in case one develops a little corrosion or other problem.

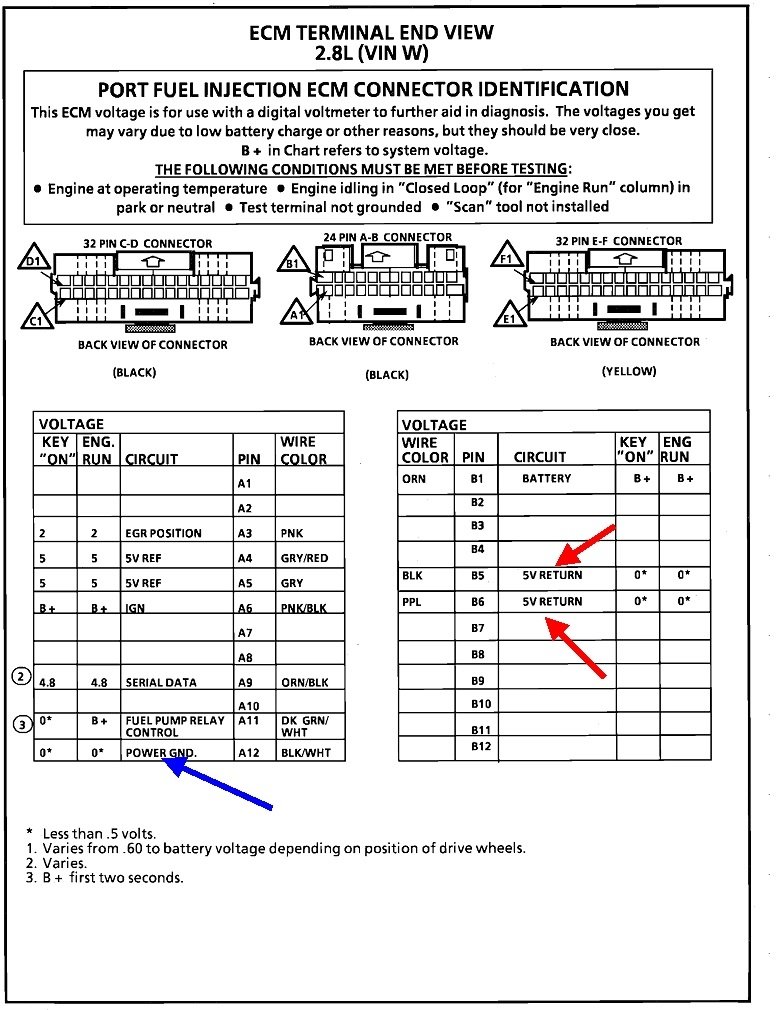

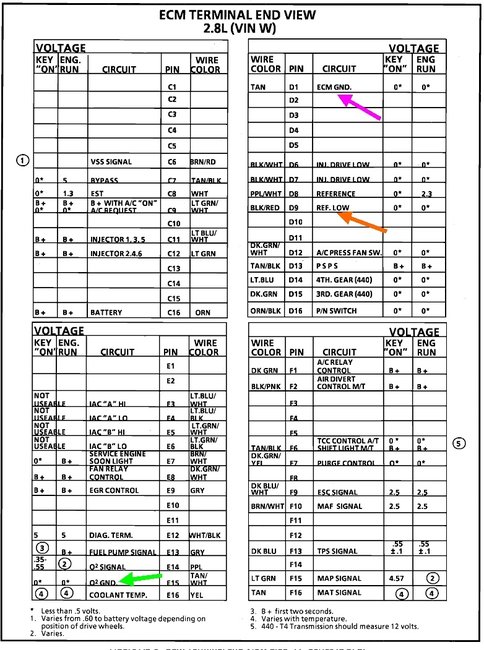

Here's the diagrams for the plugs for your Engine Computer. I found five ground wires here, but they aren't necessarily two for each circuit. For example, they use a separate wire for the oxygen sensor, (green arrow in the second diagram), probably for the same reason as a slight voltage interference from other circuits would adversely affect the O2 sensor's readings. "Reference" or "reference low" are designations for ground wires.

Do not waste your time trying to use an ohm meter to check these wires. All it takes is one tiny strand still intact to get a good reading that way. Instead, the voltage on these wires must be measured while the engine is running. That's when current flows through them and is when any excessive or undesirable resistance shows up as a "voltage drop". Put the voltmeter on its lowest range. Sometimes the voltage readings will jump around a few hundredths of a volt due to stray magnetic interference, but typically those readings will be obviously too high when there's a problem in one of the wires.

One more thing fairly common on only GM vehicles is magnetic interference from the generator. This problem started in 1987 when they redesigned them and went from the world's second-best generator design to by far the worst. They develop huge voltage spikes that can destroy the internal diodes and voltage regulator, and interfere with computer sensor signals. The battery is the key component in damping and absorbing those spikes, but they lose their ability to do that as they age and the lead flakes off the plates. That battery is the reason for repeat generator failures. Four to six replacements in the life of the vehicle is not uncommon. To reduce that number, always replace the battery at the same time as you have to replace the generator, unless that battery is less than about two years old. It will work fine in an '86 or older model.

This generator problem becomes much worse if one of the six internal diodes has failed. That causes "ripple" voltage to be real high and greatly increases the likelihood of developing voltage spikes. Most professional charging system testers measure ripple voltage automatically on a relative bar chart from "low" to "high". In addition, with one bad diode, the most current the generator will develop under the "full-load" test is exactly one-third of its rated value. Thirty amps from the common 90-amp generator isn't enough to meet the needs of the electrical system under all conditions.

To identify engine running problems caused by the generator, start with a good, fully-charged battery, unplug the small connector on the side / back of the housing, then go on a short test-drive. If the generator is causing interference with sensor signals, the symptoms will clear up when it is disabled.

Was this helpful?

Yes

No

Friday, January 29th, 2021 AT 12:25 PM