If the Engine Computer is able to adjust idle speed, especially right after start-up, the system is working at that time. Then the best suspect would be an intermittent failure, typically due to loose or corroded terminals in the connector. If there was a solid, or permanent failure, such as a cut wire, the computer would never be able to adjust idle speed. That type of defect would be detected the instant the ignition switch is turned on, and the Check Engine light would turn on right away.

If you erase the fault codes, then they don't come back right away, it's an intermittent problem. That's where you look for something that is able to "fix itself" and work at times.

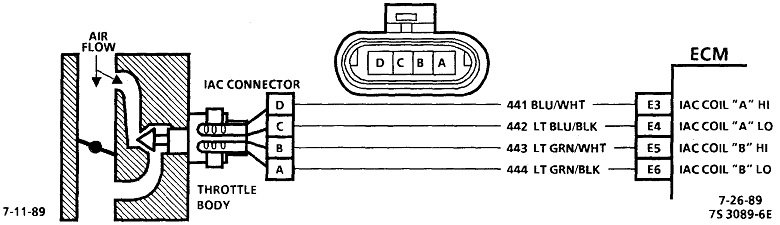

Probably the last suspect would be the idle speed motor itself. They have four electromagnetic coils of wire inside, and those wires are pretty substantial and not prone to breaking.

The system can be tested with a scanner, under the "IAC Test" or "idle speed test". That allows you to command the computer to raise engine speed to as much as 2,000 rpm in 100-rpm increments. If engine speed responds accordingly, the system is working.

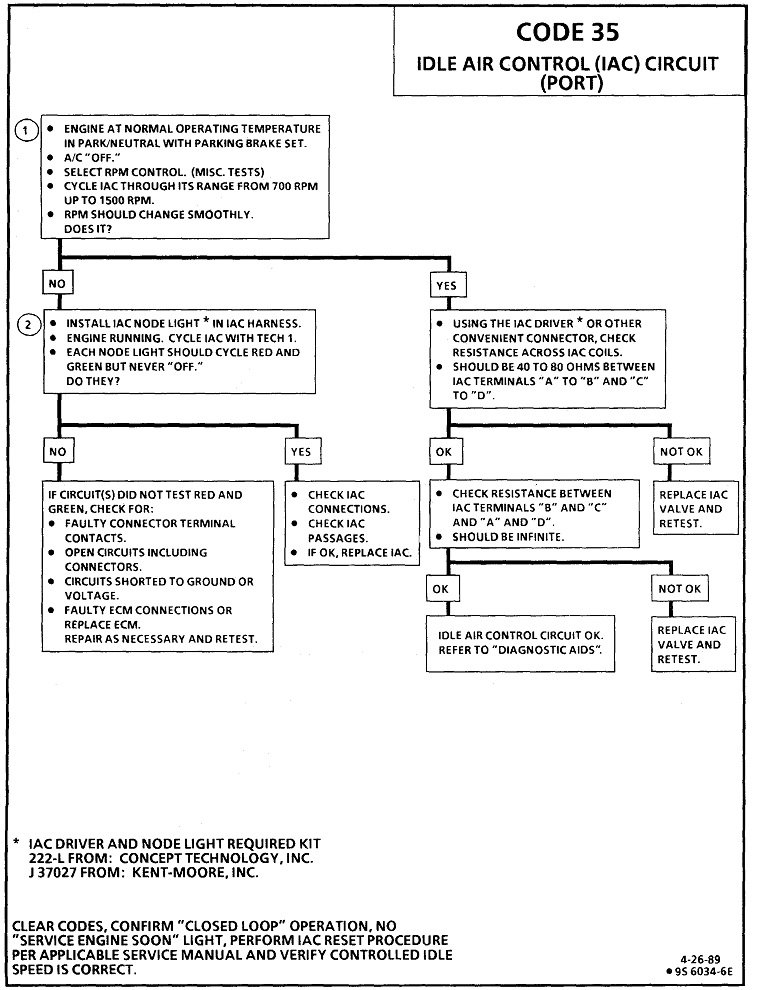

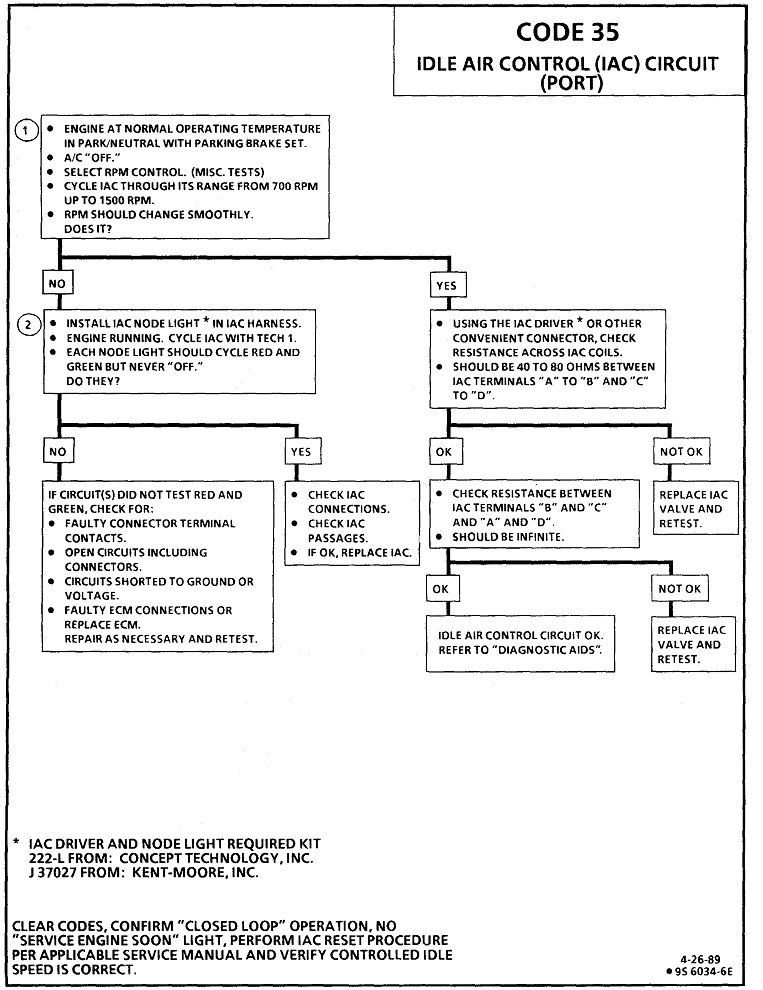

Here's GM's diagnostic steps for code 35:

CIRCUIT DESCRIPTION

Code 35 will set when the closed throttle engine speed is 300 rpm above or below the desired (commanded) idle speed for 50 seconds. Review the "Description and Operation" of the Idle Air Control (IAC) Valve operation in "Idle Speed / Throttle Control - Electronic"

TEST DESCRIPTION

Numbers below refer to circled numbers on the diagnostic chart.

1. The Tech 1 rpm control mode is used to extend and retract the IAC valve. The valve should move smoothly within the specified range. If the idle speed is commanded (IAC extended) too low (below 700 rpm), the engine may stall. This may be normal and would not indicate a problem. Retracting the IAC beyond its controlled range (above 1500 rpm) will cause a delay before the rpm's start dropping. This too is normal.

2. This test uses the Tech 1 to command the IAC controlled idle speed. The Electronic Control Solenoid (ECM) issues commands to obtain commended idle speed. The node lights each should flash red and green to indicate a good circuit as the ECM issues commands. While the sequence of color is not important if either light is "OFF" or does not flash red and green, check the circuits for faults, beginning with poor terminal contacts.

DIAGNOSTIC AIDS

A slow, unstable, or fast idle may be caused by a non-IAC system problem that cannot be overcome by the IAC valve. Out of control range IAC "Scan" tool counts will be above 60 if idle is too low, and zero counts if idle is too high. If idle speed is above 600-700 rpm in drive with an A/T, locate and correct vacuum leak. If rpm is below specifications, check for foreign material around throttle plates. Refer to Fuel Delivery and Air Induction / Throttle Body.

The following checks should be made to repair a non-IAC system problem:

Vacuum Leak (High Idle)

If idle is too high, Stop the engine. Fully extend (low) IAC with tester. Start engine. If idle speed is above 800 rpm, locate and correct vacuum leak including PCV system. Also check for binding of throttle blade or linkage.

System Too Lean (High Air/Fuel Ratio)

The idle speed may be too high or too low. Engine speed may vary up and down and disconnecting the IAC valve does not help. Code 44 may be set. "Scan" Oxygen (O2) voltage will be less than 300 mV (0.3 volt). Check for low regulated fuel pressure, water in the fuel or a restricted injector.

System Too Rich (Low Air/Fuel Ratio)

The idle speed will be too low. "Scan" tool IAC counts will usually be above 80. System is obviously rich and may exhibit black smoke in exhaust. "Scan" tool O2 voltage will be fixed above 800 mV (.8 volt). Check for high fuel pressure, leaking or sticking, injector. Silicone contaminated O2 sensors "Scan" voltage will be slow to respond.

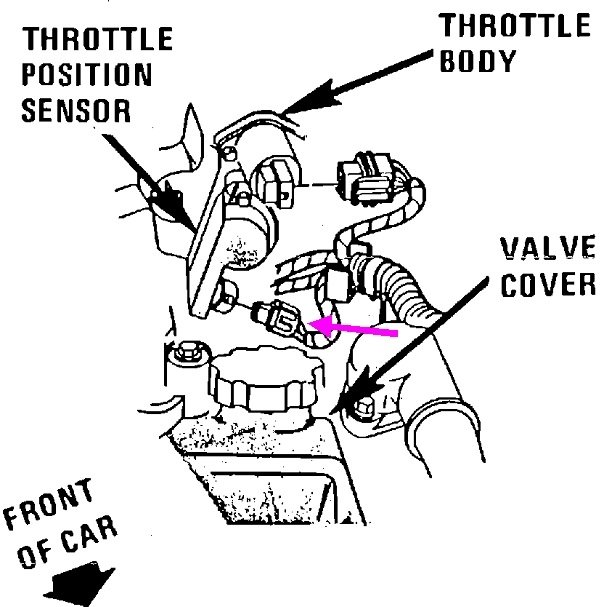

Throttle Body

Remove IAC valve and inspect bore for foreign material.

IAC Valve Electrical Connections

IAC valve connections should be carefully checked for proper contact.

PCV Valve

An incorrect or faulty Positive Crankcase Ventilation (PCV) valve may result in an incorrect idle speed.

A/C compressor or relay failure

See C-Charts Component Testing / Chart C-10A if the A/C control relay drive circuit is shorted to ground or if the relay is faulty, an idle problem may exist. See: A L L Diagnostic Trouble Codes ( DTC ) > Related Tests, Information and Procedures > Chart C-10A A/C Clutch Control

If intermittent poor driveability or idle symptoms are resolved by disconnecting the IAC, carefully recheck connections, valve terminal resistance, or replace IAC.

Refer to Diagnosis by Symptom / Rough Idle or Stalling. See: Computers and Control Systems > Symptom Related Diagnostic Procedures > Rough, Unstable, or Incorrect Idle, Stalling

Images (Click to make bigger)

Tuesday, January 5th, 2021 AT 5:14 PM