Here are diagnostic procedures.

DTC P0133, P0134: FRONT HO2S CIRCUIT SLOW RESPONSE OR NO ACTIVITY DETECTED

NOTE:

There is a Heated Oxygen Sensor (HO2S) before and one after the catalytic converter. The front HO2S measures oxygen content of exhaust gases and is used to control air fuel mixture. The rear HO2S is used to determine the efficiency of the catalytic converter. ECM calculates catalytic converter efficiency by comparing front and rear HO2S signals.

Failure Conditions

1. ECM will set DTC P0133 and illuminate MIL when ECM does not sense the following condition during 2 drive cycles:

"� Over a period of 2.3 seconds, ECM must detect 10 cycles from lean-to-rich or rich-to-lean when engine speed is 2000-3000 RPM, engine load range is 1.9-4.7 milliseconds, catalytic converter temperature is more than 673 °F (356 °C) and system is in closed loop.

"� ECM must make some correction in air fuel ratio within 133 seconds when engine speed is 1600-2400 RPM, engine load range is 1.35-1.80 milliseconds, catalytic converter temperature is more than 673 °F (356 °C) and system is in closed loop.

"� DTC P0133 indicates engine air fuel ratio is not being adjusted by front HO2S signal or ECM as expected, or as often as expected when engine is at normal operating temperature or normal use.

2. ECM will check rear HO2S operation after engine has operated for 3 minutes and 20 seconds. ECM will measure front HO2S output voltage when rear HO2S output voltage is more than 500 mV (0.5 volt). ECM will set DTC P0134 and illuminate MIL, if during 2 drive cycles the front HO2S output voltage is not 400-600 mV (0.4-0.6 volt) for 5 seconds. This DTC indicates front HO2S is not active within expected range once the engine is at normal operating temperature.

Test Procedures

1. Turn ignition on and connect scan tool to data link connector. Verify DTC P0133 or P0134 is set. If DTC P0135 is also set, repair DTC P0135 first.

2. Start engine and allow to idle at normal operating temperature. Increase engine speed to 4000 RPM. Using scan tool, monitor HO2S voltage. If voltage is zero volts, go to next step. If voltage is constant and approximately 450 mV (0.45 volt), go to step 4. If voltage varies, but stays less than 500 mV (0.5 volt - lean), go to step 6. If voltage varies, but stays more

than 500 mV (0.5 volt - rich), go to step 7. If voltage varies between 100 and 900 mV (0.1-0.9 volt), go to step 8. If voltage is constant and approximately 5.0 volts or 12.0 volts, repair short to voltage in wiring harness. When repairs are completed, clear DTCs and

verify HO2S operation.

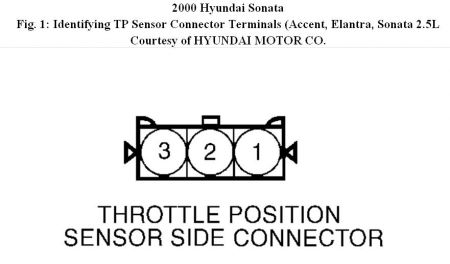

3. Disconnect front HO2S 4-pin connector. If DTC P0133 is set, voltage displayed on scan tool should be approximately 450 mV (0.45 volt). If DTC P0134 is set, voltage displayed on scan tool should be approximately 500 mV (0.5 volt). If voltage is as specified, replace suspect HO2S. If voltage is not as specified, repair short to ground in Yellow wire between HO2S connector terminal No. 1 and ECM 88-pin connector terminal No. 12. When repairs are completed, clear DTCs and verify HO2S operation.

4. While engine is operating, backprobe between HO2S 4-pin connector terminals No. 1 and 2, and measure voltage. If voltage changes from less than 500 mV (0.5 volt) to more than 500 mV (0.5 volt), go to next step. If voltage does not change, replace HO2S. When repairs are completed, clear DTCs and verify HO2S operation.

5. Turn ignition off. Disconnect front HO2S 4-pin connector and ECM 88-pin connector. Using a jumper wire, connect HO2S connector terminal No. 1 to ground. Measure resistance between ground and ECM connector terminal No. 12. If resistance is one ohm or less, ensure ECM connector terminals are clean and tight. If PCM connector are okay, replace front HO2S. Clear DTCs and verify HO2S operation. If problem persists, replace ECM. If resistance is more than one ohm, repair open or cause of high resistance in circuit between HO2S and ECM. When repairs are completed, clear DTCs and verify HO2S operation.

6. If voltage varies and is always less than 500 mV (0.5 volt - lean), check air inlet downstream of Mass Airflow (MAF) sensor for leaks or damage. Check exhaust manifold for cracks or leaks. If any leaks or damage is found perform repairs as necessary. If no leaks or damage is found, go to next step.

7. Perform fuel pressure inspection. If fuel pressure is within specification and no pressure leak-down is detected, go to next step. If fuel pressure is not as specified, repair fuel system as necessary. When repairs are completed, clear DTCs and verify HO2S

operation.

8. Turn ignition off. Disconnect ignition coil connector. Connect voltmeter between negative battery cable and cable attachment located on engine. Measure voltage drop across negative battery cable while cranking engine. If voltage drop is less than 0.5 volt, go to next step. If voltage drop is more than 0.5 volt, replace negative battery cable. When repairs are completed, clear DTCs and verify HO2S operation.

8. Disconnect negative battery cable and measure resistance between generator housing and engine ground point. If resistance is one ohm or less, go to next step. If resistance is more than one ohm, clean mating surfaces of generator housing and engine. When repairs are completed, clear DTCs and verify HO2S operation.

10. If MIL is illuminating intermittently and DTC P0133 is set, problem is most likely a poor ground circuit. Clean negative battery terminal and engine ground. In addition, clean mating surfaces of generator housing and engine. If MIL was illuminated and DTC P0133 or P0134 is set, replace front HO2S. When repairs are completed, clear DTCs and verify HO2S operation.

Thursday, September 2nd, 2010 AT 12:30 PM