Dandy photos. If you were to cut a regulator open, you'd be amazed at how little is inside it. There's basically a round disc that's held closed with a spring. Pressurized fuel pushes that disc off its seat, then rushes past it and back into the tank. No powder or any other kind of debris is going to get stuck in there. Anything large enough to be caught under that disc can't make it through the screen on the fuel pick-up tube, and if that screen was cut or removed, the debris would lock up the fuel pump. It also wouldn't make it through the filter.

As for the powder you found, I suspect that is an additive in the gas that is normally dissolved and held in suspension. If that powder could make it as far as the regulator, it also made it to the injectors. Those have extremely fine-mesh screens to trap even the tiniest debris. A powder that doesn't dissolve would plug those screens in short order.

Chrysler is well-known for buying parts from multiple suppliers. This used to make replacing just one part of a half shaft somewhat confusing because at least four manufacturers supplied them, and all used different parts even though the shafts as an assembly easily interchanged. Chrysler did that because some suppliers couldn't keep up with production needs, and they weren't held hostage if the people at one plant went on strike. The same can be true of fuel pressure regulators. The only size that is important is the outer diameter of the two o-rings. You could have an old and a new regulator made by different manufacturers, or at different times after one made a design change. The hole in the middle of the smaller o-ring has no bearing on the calibration or pressure. It has to be large enough to pass 99 percent of the gas the pump is moving. That can easily be well over 50 gallons per hour. Only a little is tapped off to go through the injectors and into the engine. The rest goes back to the tank through the return line where it flows up a ramp around the outside of a bowl the fuel pick-up and screen sits in. That flow creates a venturi action that draws more fuel with it to keep that bowl full. Planting the pick-up in that bowl prevent the gas from running away from the pick-up when fuel level is low and you're going around a corner or up or down a hill. It's also how they keep a four-inch-tall bowl full when there's less than an inch of gas left in the rest of the tank.

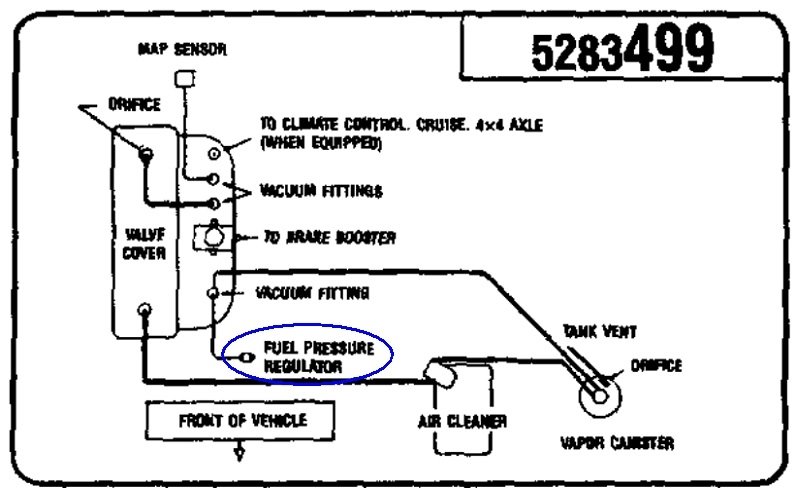

To finish this wondrous story, everything related to engine performance and emissions is designed to assume fuel will be held at a specific pressure. That is set by the strength of the spring in the fuel pressure regulator. The problem is there's two forces acting on a molecule of fuel as its about to leave the tip of the injector. One force is pressure pushing on it, and the other is intake manifold vacuum pulling on it. During acceleration or periods of high load, vacuum is real low, so that pulling force is gone. Fuel spraying from the injector is a factor of only pressure. That would make for a lean condition. During coasting, vacuum is real high. That would tug harder on the gas resulting in a very rich coasting condition. Both conditions are solved by adding the vacuum port to the regulator. That vacuum pulls on the disc in the regulator and helps the pressurized fuel to open it easier. That lowers the fuel pressure during coasting while vacuum is higher. Overall, the total of the two forces acting on the molecule of fuel stays the same.

There's some common problems to be aware of. The first has to do with that screen on the pick-up tube in the tank. I've had them become plugged four times on three of my vehicles. The first two were with carbureted engines. The last two were on my '88 Grand Caravan, about 200,000 miles apart. Both times with the fuel-injected Caravan, the symptoms were the engine ran fine at highway speeds and when accelerating, but it would stall when coasting. At higher speeds and when under load, vacuum is low so fuel pressure goes high. Higher pressure is created by the regulator being harder to open to let the gas pass through it. Being harder to get through the port, volume goes down, lets say to 25 gallons per hour, for example. Remember, the engine might be using two gallons per hour. That leaves 23 gallons per hour going right back into the tank. The partially-plugged screen can still pass 25 gallons per hour. Now, when you coast up to a stop sign or turn-off, vacuum goes high. To prevent a rich condition, fuel pressure goes down. That's the result of making the port in the regulator easier to open. Being easier to get through the regulator, fuel volume goes way up, possibly to over 100 gallons per hour. Now is when that partially-plugged screen becomes a problem. It limits volume so much, the pump can't supply enough to keep pressure up to where it should be.

The second time this happened to my van, it was so intermittent and so elusive, I drove around for over a year with a fuel pressure gauge strapped to the radio antenna. Under the right conditions, I would see fuel pressure drop from a normal 45 psi to less than 20 psi. The engine didn't start to sputter until it got to 15 psi. Many engines won't run right or even start if fuel pressure is as little as five pounds too low. This second time, I also had a lot of pin holes in the top of the tank. I replaced it and just the screen that clipped onto the old pump assembly. Never had the stalling problem after that.

The second common problem came from a service bulletin issued by Chrysler. A lot of people were replacing locked-up fuel pumps with aftermarket pumps, then those would lock up in a week or two. After getting them replaced under warranty five or six times, out of frustration they'd by a pump from the dealer and have no more problems. Chrysler determined the problem had nothing to do with the aftermarket pumps. In fact, many of them come from the same supplier that sells them to Chrysler. Their pumps are built to very tight clearances to make them quiet, but they found that microscopic debris in the tank was locking up the impellers. Each new pump collected some of that debris, then locked up too. It was just a coincidence that the debris was gone by the time the pump from the dealer was installed. The service bulletin told us when we ran into a lock-up fuel pump, to take the gas tank to a radiator repair shop to have it stream-cleaned before installing the new pump.

Years later a friend running a small engine repair shop showed me a sample of gas with ethanol in it. It was real cloudy with an inch of "mud" at the bottom of the jar. He told me that was mold growing on that alcohol. I have to wonder if that wasn't what was plugging the pick-up screens. Either way, it never made it to the injectors. One replacement pump and two screens were the only fuel system repairs in over 440,000 miles, then the van rusted apart.

Sunday, May 23rd, 2021 AT 7:00 PM