Installation procedures are below for your vehicle's timing belt..

INSTALLATION:

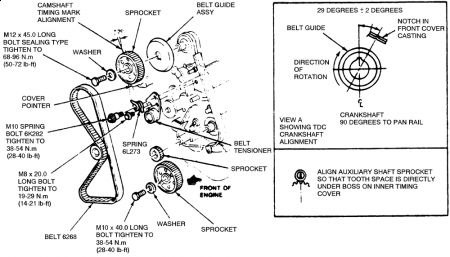

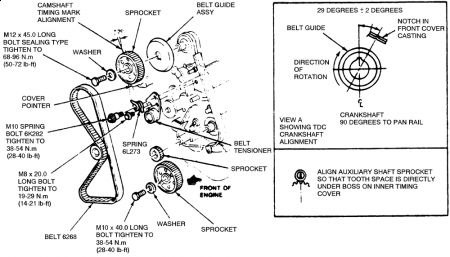

Position the crankshaft sprocket to align with the TDC mark and the camshaft sprocket to align with the camshaft timing pointer.

On 1989-90 vehicles, remove the distributor cap and set the rotor to the No. 1 firing position by turning the auxiliary shaft.

Install the timing belt over the crankshaft sprocket and then counterclockwise over the auxiliary and camshaft sprockets. Align the belt fore-and-aft on the sprockets.

Loosen the tensioner adjustment bolt to allow the tensioner to move against the belt. If the spring does not have enough tension to move the roller against the belt, it may be necessary to manually push the roller against the belt and tighten the bolt.

Remove a spark plug from each cylinder in order to relieve engine compression and to make sure the belt does not jump time during rotation in the next step.

Rotate the crankshaft two complete turns in the direction of normal rotation to remove the slack from the belt.

For 1992-93 (VIN M) engines, have an assistant hold the crankshaft pulley from turning (this can be done in a variety of ways including at the flywheel with a holding tool, or with a wrench and a prybar at the pulley bolts). Turn the camshaft sprocket counterclockwise using a torque wrench, until the torque setting reads 40 ft. lbs. (54 Nm), then while still holding both the camshaft and crankshaft from turning, tighten the tensioner adjustment and pivot bolts.

Tighten the tensioner adjustment bolt to 29-40 ft. lbs. (40-55 Nm) and pivot bolts to 14-22 ft. lbs. (20-30 Nm).

Recheck the alignment of the timing marks.

Install the crankshaft belt guide.

On 1989-90 vehicles, install the crankshaft pulley and tighten the retaining bolt to 103-133 ft. lbs. (140-180 Nm). On 1991-92 vehicles, proceed as follows:

Install the timing sensor onto the dowel pin and tighten the two longer bolts to 14-22 ft. lbs. (20-30 Nm).

Rotate the crankshaft 45 degrees counterclockwise, then install the crankshaft pulley and hub assembly. Tighten the bolt to 114-151 ft. lbs. (155-205 Nm).

Rotate the crankshaft 90 degrees clockwise so the vane of the crankshaft pulley engages with timing sensor positioner tool T89P-6316-A, or equivalent. Tighten the two shorter sensor bolts to 14-22 ft. lbs. (20-30 Nm).

Rotate the crankshaft 90 degrees counterclockwise, then remove the sensor positioner tool.

Rotate the crankshaft 90 degrees clockwise and measure the outer vane-to-sensor air gap. The gap must be 0.018-0.039 in. (0.458-0.996mm).

Install the spark plug which was removed from each cylinder.

Install the timing belt front cover.

Connect the negative battery cable.

For distributor equipped (VIN A) engines, check the ignition timing.

Thanks for using 2CarPros.com!

Wednesday, April 1st, 2009 AT 8:26 PM