Can be intake manifold gasket, or in sevser cases the heads also need replacing.. heres the tech bulliten.:

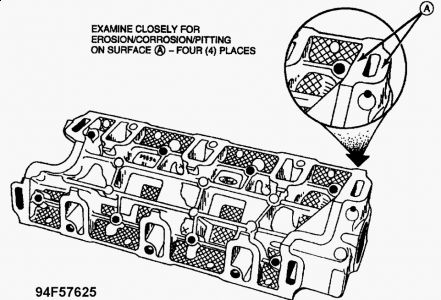

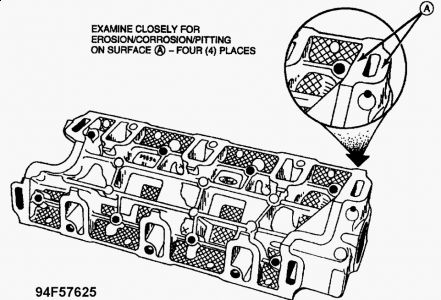

4.0L COOLANT LOSS - REVISED INTAKE MANIFOLD GASKET TECHNICAL SERVICE BULLETIN Reference Number(s): 95-9-10, Â Date of Issue: Â May 8, 1995 Related Ref Number(s): 95-9-10 ARTICLE BEGINNING CONDITIONS COOLING SYSTEM - LOSS OF COOLANT -4.0L ENGINE - REVISED INTAKE MANIFOLD GASKET AND INSTALLATION PROCEDURE LEAKS - COOLANT -4.0L ENGINE - REVISED INTAKE MANIFOLD GASKET AND INSTALLATION PROCEDURE APPLICATION Model(s): Ford Light Truck: 1992-94 Aerostar, Explorer, Ranger Bulletin No.: 95-9-10 Date: May 8, 1995 ISSUE Coolant loss, with no visible sign of leakage, may occur on some vehicles. This may be due to internal leaks from a failed intake manifold gasket caused by loose intake manifold bolts, a fouled intake manifold, pitting/corrosion, or loose cylinder head bolts. ACTION Refer to the following procedures for service details. INSPECTION PROCEDURE 1. Run the engine for 10 minutes, or as required, to build pressure in the cooling system for a leak inspection. Examine the radiator, side tanks, coolant recovery bottle, hoses and connections, intake manifold, cylinder heads and block for external coolant leaks. If no external leak can be found, then the concern may be with the lower intake manifold gasket, intake manifold pitting/corrosion, or with low cylinder head bolt torque. 2. Measure the cylinder head bolt torque. If torque is less than 80 Nm (59 lb-ft), replace Cylinder Head Gasket (F5TZ-6051-A RH, and F5TZ-6051-B LH) using the procedure in this TSB NOTE: Due to air being trapped in the cooling system, it is not unusual to add 4-7 oz (118-207 ml) coolant up to 7500 miles (12,000 km) after initial fill.article. 3. If coolant loss continues, even with proper head bolt torque, remove intake manifold and remove all old gasket material and any coolant residue with a soft non-metallic or aluminum wire brush. Inspect manifold for corrosion/erosion/pitting damage at the four (4) water passages. See Fig. 1 . If damaged, the intake manifold must be replaced. 4. Replace the lower intake manifold gasket with the new Carrier-type Intake Manifold Gasket (F5TZ-9439-A). Use the procedures found in this TSB article. DISASSEMBLY PROCEDURE INTAKE AND CYLINDER HEAD GASKETS Service the intake manifold (lower) and cylinder head gaskets per the appropriate Powertrain/Drivetrain Service Manual, when required. INSTALLATION ASSEMBLY PROCEDURE AFTER REMOVING BOTH CYLINDER HEAD AND INTAKE MANIFOLD 1. Remove all old gasket material with a soft non-metallic or aluminum wire brush. 2. Before installing the new gasket, remove all old sealer from the intake, heads and block surfaces, and check for proper condition. Clean all exposed areas very thoroughly with Metal Surface Cleaner (F4AZ-19A536-RA) or denatured alcohol. 3. Position cylinder head gaskets on cylinder block. Install cylinder head locating dowels. Position the cylinder heads onto the gaskets and locating dowels. See Fig. 4 . CAUTION: Do not use a sand disk or similar power tool. If the intake manifold surface is pitted (Fig. 1 ), then the manifold must be replaced. CAUTION: Do not use a sand disk or similar power tool. NOTE: The 4.0L engine should always be assembled using new cylinder head bolts. NOTE: If the engine received has bolts instead of guide studs (as in item 3, Fig. 6 ), then temporarily replace bolts with guide studs (E805676-S72). If guide studs are not in stock, fabricate by removing the heads from two (2) bolts (W700166-S309). install them snugly in the cylinder block holes that match holes 3 and 4 (Fig. 7 ). if guide studs were on the vehicle received, then loosen the studs 1/2 turn before proceeding. NOTE: The cylinder head(s) and intake manifold are torqued alternately

Friday, August 16th, 2019 AT 2:09 PM

(Merged)