Hi guys. I think it is time to stop, take a step back, and learn how these systems work before I, ... I mean you, create all kinds of new problems. I am speaking from experience because I have been there with TV's and with cars.

The first red flag is, "car will not start it acts like it wants to but does not I was told". That is how unknowledgeable car owners describe problems, and it tells us very little. You need to describe the exact symptoms, such as, "cranks too slowly to start", cranks at normal speed, sputters a little, but will not run", etc.

I have never seen a 300-amp alternator, but regardless, that is absolutely not the solution to anything. You need to start with the charging voltage test ASEMASTER6371 and I discussed right at the beginning. It appears you have not done the professional tests yet like we need to see. That is like your doctor taking out your appendix without doing any tests to verify that is necessary. Once he is done with that surgery, he can move on to solving the headache you were complaining about. You could dump a highly-desirable Chrysler high performance 340 c.I. Into your riding lawn mower, but if the lawn is so small you have to slow down for lots of turns, you are not going to get the job done any faster.

You must understand too that a larger alternator will not put out any more current than the original one. If the electrical system needs 57 amps to run everything that is turned on and operating, and to recharge the battery, 57 amps is all you are going to get, even if you put in a 1000-amp unit. The larger one simply has a higher maximum capacity. It is able to provide the higher current, but the only time it is going to do that is during the full-load output current test, and then it is going to blow the fuse or fuse link wire which was selected to match the size of the original alternator. If the original alternator was a 140-amp unit, there is nothing on the car you can turn on at the same time to draw close to that much, even with a totally discharged battery. To put on an alternator with a higher capacity means you're paying for something you can never use.

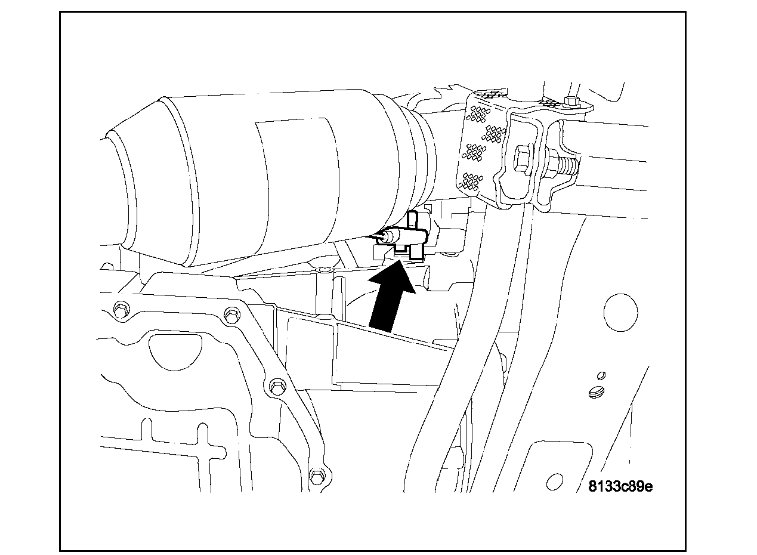

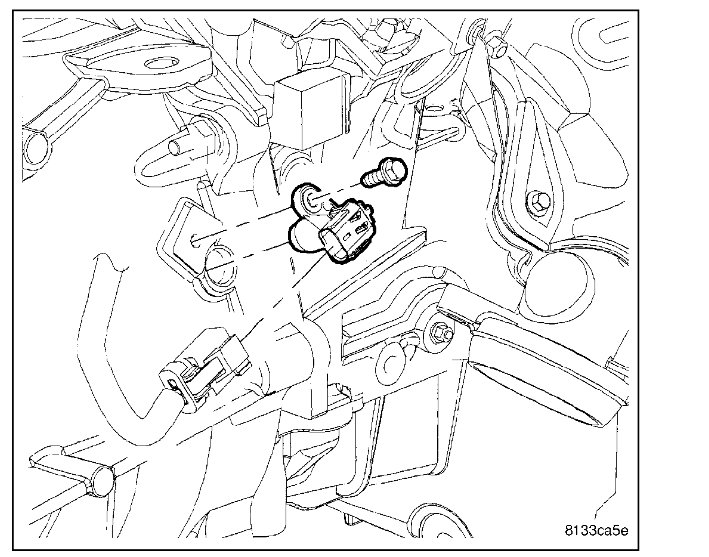

Either the crankshaft position sensor or the camshaft position sensor can cause a crank/no-start, but for intermittent problems, they commonly act up by becoming heat-sensitive on any brand of car, then they work fine again after cooling down for about an hour. The most common symptom is the engine starts cold, and runs normally until it is warmed up and stopped, as in when stopping for gas. During "hot soak", heat migrates to the sensors and causes them to fail. After sitting for a good hour, they work again and the engine starts right up like normal.

Related to this, it is important to mention that when these two sensors fail, at least on Chrysler products, they often do not set diagnostic fault codes just from cranking the engine. They set when a stalled engine is coasting to a stop on the highway. Always read and record the fault codes before disconnecting the battery to do other services because that erases the codes, then that valuable information is lost. Other codes will likely set again, but not for these two sensors, making verifying the diagnosis difficult.

This comment does not apply here, but it is worth mentioning to make my wondrous point. On older models, the air gap for the crankshaft position sensor was critical and had a simple procedure that if not followed, often led to intermittent stalling and/or intermittent hard starting. Lots of sputtering and backfiring during cranking before the engine finally started running normally. If you are not aware of this, you just introduced a new problem with new symptoms totally unrelated to what you are trying to fix. That is what I am afraid you're going to do by throwing random parts at a problem.

This also may not apply here, but I am going to share it to show what you could be running into. I learned that on my rusty trusty 1988 Grand Caravan, in real cold weather, or when the battery was weak, the stiff engine would load down the starter, and the resulting higher-than-normal current would load down the battery for the first one or two seconds. Without going into lots of exciting motor and electrical theory, when the battery's voltage got drawn down for just that one or two seconds, the Engine Computer turned off the ignition coil circuit. After that couple of seconds, starter speed picked back up to normal, and the injectors were pulsing just fine, but spark never came back until the ignition switch was turned all the way off, then back on, to reset the computer. One really cold winter with an eight year-old battery, ma cranked on and off all day long, but the engine never started. I came home with a new battery, then the engine fired right up. What I forgot about was all that raw gas that washed down past the piston rings and diluted the oil. She only made it fifty miles before the bearings were destroyed. (That is why we always tell customers we want to change the oil in their engine after repairing a spark-related no-start condition). Years later I ran into the same problem with that van and another real old battery, but this time I knew to simply crank a little, stop, then turn the ignition switch fully off before trying again.

The point is you could have a drain on the battery, a bad diode in the alternator, or some other related problem, and this new, hard-starting problem could be a result of that. We need to address that first before we go looking for sensor problems. No matter what you are complaining about to your doctor, why do they always start with checking your blood pressure? Voltage is electrical pressure, and that is what you need to start with. The critical numbers are battery voltage with everything turned off, then the same voltage with the engine running. ASEMASTER6371 will continue on once we know where we stand with those numbers.

Wednesday, November 21st, 2018 AT 4:52 PM