Aha! That's not a creaking noise. That's a loud clicking once per wheel revolution. That's caused by one of two things. The more common is loose lug nuts. It's important to always use a torque wrench on the lug nuts. Overtightening is just as bad as under tightening. Under-torqued nuts leads to them backing off from wheel movement and grinding away of the contact surfaces. Once that begins, there's no stopping it and the nuts will never remain tight after that. If you do tighten them again, the clicking noise will go away for a little while, but will return withing a few miles. That's the clue. The only repair is to replace the wheel and the lug nuts.

The other cause is a combination of a warped rotor and grooves worn into the pads' mounting surface. Rotors can warp in one of two ways. One way is "thickness variation". The thickness is different at different sections of the rotor. As the thicker area enters the pads, it pushes the piston back into the caliper. That pushes brake fluid up and pushes the brake pedal toward you. You feel that as a pedal pulsation.

The other, probably more common type of warping is the thickness is nice and even all the way around, but the entire friction surface is not perfectly parallel to the mounting surface. Think of the carnival sideshow where the performer is spinning plates on top of long sticks. The plate is the same thickness in all areas, but it's wobbling as it slows down. If the wobbling of the rotor gets bad enough, its mass will tug back and forth on the steering linkage, so you'll feel that in the steering wheel, but possibly not in the brake pedal.

The clicking in this case comes from grooves worn in the knuckle the pads rest on. While driving, the rotor is still wobbling, but the caliper and pads are free to walk back and forth freely, so no noise occurs. It's during braking that very high force pushes the pads against the mounting surface, and they'd rather not move sideways because of that force. Since the rotor is wobbling back and forth a little, it forces the pads under pressure to be forced into and out of those worn spots twice per wheel revolution. That creates the clicking noise.

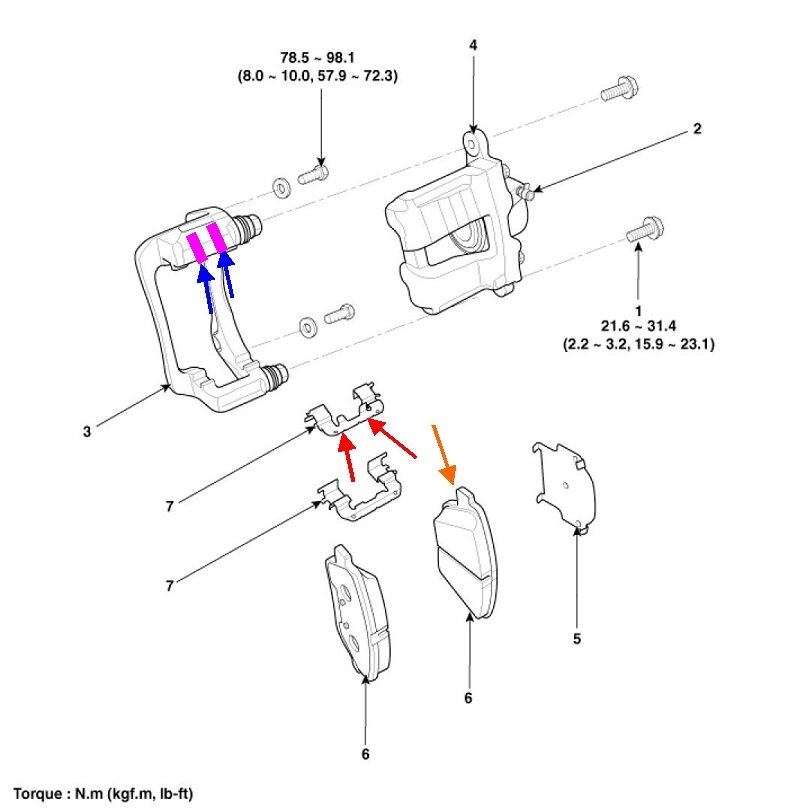

I added some nifty arrows to the exploded view to try to describe this better. The orange arrow is pointing to one of the mounting ears for the inner pad. That ear is pressed against the mounting bracket by the pink spot on the right, (blue arrow). That's one of the places we grease. When the rotor is warped, even a little, that ear grinds back and forth during braking, wearing the pink grooves into the surface. Even that may not cause a noise yet because the pads are remaining within those worn spots. It's when anything changes where the pads ride that can setup the clicking noise. New, thicker pads will push the inner pad's backing plate closer to the caliper, (away from the rotor), placing the mounting ear outside that worn area. Now, as the rotor wobbles back and forth, it pushes the pad's ear into and out of that worn spot. That makes the clicking noise.

There's a number of ways to address this. For most domestic vehicles, the easiest is to replace the mounting bracket or steering knuckle. For most imports this isn't a concern because they use stainless steel inserts to become the wear surfaces. The two red arrows are pointing to one of those inserts. This is the one that gets the forces put on it when braking going forward. Those inserts stand up to wear really well, but you still usually get new ones with new pads. If you don't, they are available as a repair kit.

The less-desirable repair method is only used on rare vehicles when replacement parts are hard to come by. That is to heat the wear surfaces for a long time with an acetylene torch, then fill in the worn spots with a wire-feed welder. Grind those surfaces smooth and flat to restore the original shape. These mounts are made of cast iron which is porous. They will crack or shatter when trying to weld to them. The preheating prevents that, but I've seen people take up to three hours of preheating to repair cracked exhaust manifolds. I've made this type of repair a half dozen times, and preheating for as little as 20 minutes was enough to prevent shattering. I've done this on these pad mounting surfaces, and with cracked anti-lock brake tone rings on outer CV joints.

The first vehicle I ran into with this clicking noise was on a Dodge Dakota 4wd in the late '90s. The final observation was we ran the vehicle, in gear, on a hoist, with the left front wheel off, and we could easily see the caliper walking left and right as the rotor went around. Replacing the knuckle and lubing those points solved the noise. Machining the rotor prevented a repeat failure.

Be aware, related to this, most new rotors are made in China and will warp within the first three months. Unlike the thickness variation I mentioned earlier, this type of warping creates excessive "lateral runout". When we make parts from cast iron, we set them aside for three months to age before they get their final machining. The Chinese cast 'em, machine 'em, pack 'em, and ship 'em, then they age on your vehicle. Once they warp, as most will do, a simple light machining on a brake lathe is the final solution. The people at most auto parts stores will do this for you for free. Those who demand new rotors under warranty will have the same problem in another three months. This usually only happens once.

Given that your system uses these stainless steel inserts, I'm growing more suspicious the lug nuts and mating contact points on the wheel are worn. A sure-fire way to prove this is when the noise is occurring, stop and retighten the lug nuts. The clicking noise will be gone for anywhere from a few miles to a day or two. Over-tightening won't help because the contact points between the nuts and wheel have to match perfectly, and there must be no grease on those points. When those surfaces no longer match, the friction that holds the nuts tight is gone. That's why the nuts and wheel have to be replaced.

It's okay to put a very light film of grease on the wheel studs for most domestic vehicles, but more is not better. The nuts should be run on by hand, then tightened with a torque wrench. When too much grease is used, or when the nuts are spun on with air tools, the grease can build up ahead of the nut, then get flung onto the friction surface. Those surfaces have to be kept dry to hold the nuts tight.

Most import vehicles use anodized wheel studs. That's a silver, light blue, or light gold coating that is a lubricant. No grease must be used on those studs. Grease will dissolve the coating, leading to galling, and stripped threads the next time the nuts are removed.

Image (Click to make bigger)

Saturday, November 2nd, 2024 AT 4:12 PM