Introduction

This guide provides a highly detailed and technical step-by-step explanation of the operation of an automotive brake caliper. A brake caliper is designed to utilize brake fluid under pressure to transfer hydraulic force from the brake master cylinder to the brake pads. The brake pads then contact the rotating brake rotor to slow the car down through friction. A brake caliper is typically mounted into the caliper mount which embodies two caliper slides allowing the caliper to "float".

There are two basic designs of brake caliper mounting, fixed and floating. A fixed position brake caliper is bolted to the mount and is not allowed to move. This kind of design is constructed with one or more pistons on either side of the caliper. The floating style of caliper, which is more common is mounted to the caliper mounting bracket using slide bolts which allow the caliper to "float" as the brake pads wear, this design uses a piston on the inboard side of the caliper. Brake calipers can have from 1 to 6 pistons depending on the manufacturer's design.

All brake calipers are fitted with a brake fluid bleeder near the top which allows air to escape from the brake system. If air is allowed in the system it can cause a spongy brake pedal or low brake pedal. A brake caliper piston is sealed to the brake caliper housing using a main piston seal. This seal allows the piston to move back and forth without allowing brake fluid to leak and is protected by a dust seal that helps keep debris from contaminating the integrity of the main seal.

Components of a Brake Caliper

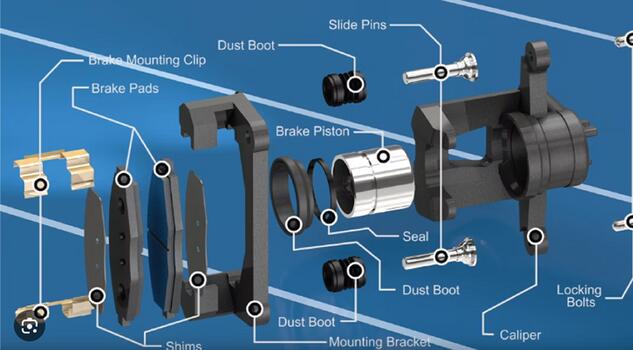

A typical brake caliper consists of the following components:

- Caliper Housing: The main body that holds the other components. It is typically made of cast iron or aluminum.

- Pistons: Cylindrical components that push the brake pads against the rotor. They are usually made of steel or aluminum.

- Brake Pads: Friction materials that contact the rotor to create braking force.

- Brake Fluid Channels: Pathways through which brake fluid flows to and from the pistons.

- Bleeder Valve: A valve used to remove air from the brake fluid system.

- Seals and Dust Boots: Components that keep contaminants out and brake fluid in.

Here is an exploded view of a typical automotive brake caliper.

A Deeper Dive

All automotive brake system are based on the basic hydraulic principle. When the brake pedal is depressed by the driver it activates the brake master cylinder which in turn forces hydraulic pressure into the brake caliper. The hydraulic pressure forces the caliper piston to move outward and engage the brake pads onto the brake rotor. Because the brake caliper articulates throughout the suspension and steering systems a flexible brake hose is used to transfer the hydraulic pressure into the brake caliper.

When hydraulic pressure enters the brake caliper, it displaces the caliper piston or pistons depending on the caliper design forcing it outwards. Piston seals keep the brake fluid from leaking while holding pressure inside of the caliper housing. Two copper sealing washers are used at the connection to the caliper from the flexible brake hose which must be replaced at each use. Once these washer have been "crushed" to the caliper it is difficult to get them to reseal for a second time.

There is also a dust shield bellow that protects the mains caliper seal from dirt and moisture which can make the seal leak while creating pits inside the caliper sleeve. This is why the caliper should be replaced when it starts leaking, are you can also rebuild the caliper by purchasing a brake caliper rebuild kit.

Occasionally the brake caliper will start to leak after a brake job has been performed, this is because the caliper piston has been working in one position for thousands of miles and then is forced inwards which can create a leak because of the new sealing area it is now subject to with the new brake pads.

The brake pads are held inside the caliper using retainer clips during the braking operation, and while the caliper has been removed. Concurrently, anti-rattle clips are attached to the caliper mounting bracket which are attached to the spindle to help eliminate brake caliper rattle while not in use and at the first moment the brakes are applied.

Maintenance

We recommend complete brake fluid systems flushes to help keep moisture and other brake fluid contaminates out the caliper to prevent the seal from failing. Also, to help the caliper move freely, service the caliper slides while inspecting the anti-rattle clips and retainers.

Conclusion

The brake caliper is an essential part of the braking system and must be cared for to maintain the braking system operation of your car and keep you driving down the road safety for years to come.

Credits

This guide knowledge base was created by the 2CarPros Team, and by Ken Lavacot: Automobile repair shop owner and certified master automobile technician of over 30 years. If you have question or need help please ask one of our experts we are happy to help. Please visit our 2CarPros YouTube Channel.