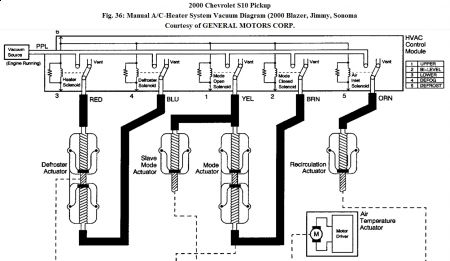

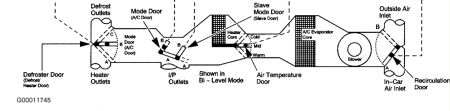

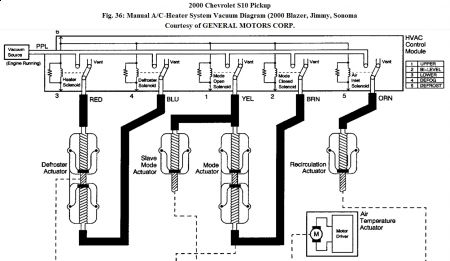

When the air blows out of the defrost vents only, it's almost always a vacuum leak, or broken vacuum line from the engine into the heater control. Look for the Purple vacuum line that comes off the intake are, goes to t check valve, then to a vacuum reservoir, and into the car. If that's all good, use a hand vacuum pump, and see if all the servos under the dash hold vacuum. Steps to take by the book...

INSUFFICIENT HEAT DIAGNOSIS 1. Perform HEATER OUTPUT TEMPERATURE CHECK . Go to next step. 2. Common conditions for insufficient heating are as follows: à   A leak in the cooling system. à   A low coolant level. à   A loose or worn drive belt. à   A leaking or kinked heater hose. à   A cracked or missing radiator cap seal. à   A stuck thermostat. Repair condition(s) as necessary and recheck heater operation. See HEATER OUTPUT TEMPERATURE CHECK . If heater system operates normally, system is repaired. If heater system does not operate normally, go to next step. 3. Turn ignition switch to ON position. Set mode control to floor/heat position. Set blower speed to HI position. Set temperature control to full hot position. If airflow from floor outlet is high, go to next step. If airflow from floor outlet is not high, go to step 7. 4. Move blower control through all positions. If blower speed changes, go to next step. If blower speed does not change, go to step 11. 5. Perform HEATER OUTPUT TEMPERATURE CHECK . If temperatures are as specified, go to next step. If temperatures are not as specified, go to step 12. 6. Inspect following areas of vehicle for cold air leaks and repair as necessary: à   At cowl, below windshield. à   Inside heater case, at door seals. à   Inside outlet vent ducting. Perform HEATER OUTPUT TEMPERATURE CHECK . 7. Perform FUNCTIONAL TEST . If system operates as specified, repairs are complete. If system does not operate as specified, go to next step. 8. Check airflow from instrument panel vent outlets. If airflow from vent outlets is high, go to next step. If airflow from vent outlets is not high, go to step 17. 9. Move mode control to floor/heat position. A small amount of air should flow from defroster outlets. If airflow from defroster outlets is as specified, go to next step. If airflow from defroster outlets is not as specified, go to step 18. 10. Remove floor air outlet and check for obstructions. Remove or repair obstructions as necessary. Move blower control through all positions. If blower speed changes, go to step 9. If blower speed does not change, go to next step. 11. Check following components of blower motor controls and repair as necessary: à   Blower motor switch à   Blower motor resistor/relays à   Blower motor system wiring harness Perform HEATER OUTPUT TEMPERATURE CHECK . If temperatures are as specified, go to step 6. If temperatures are not as specified, go to next step. 12. Turn temperature control to full hot position. Check temperature valve position. If temperature valve is fully closed, go to next step. If temperature valve is not fully closed, go to step 22. 13. With temperature control in full hot position, start engine and allow to idle. Check temperature of both inlet and outlet heater hoses. If temperature of air around each heater hose is about the same, 85 °F (24 °C), go to next step. If temperature of air around each heater hose is not the same, go to step 23. 14. Remove heater hoses at heater core and check that heater hoses are connected properly. If hoses are properly installed, go to next step. If hoses were not properly installed, go to step 25. 15. Backflush heater core and service cooling system. Reconnect heater hoses and refill cooling system. Start engine and bring it to normal operating temperature. Recheck temperature of both inlet and outlet heater hoses. If temperature of air around each heater hose is about the same, 85 °F (24 °C), go to next step. If temperature of air around each heater hose is not the same, go to step 23. 16. Replace heater core. See removal and installation procedures in appropriate HEATER SYSTEMS article. After heater core replacement, perform HEATER OUTPUT TEMPERATURE CHECK . 17. Set mode control to defrost position. Check airflow from defroster outlet. If there is little or no airflow, go to next step. If airflow is okay, go to step 10. 18. Move blower control through all positions. If blower speed changes, go to next step. If blower speed does not change, go to step 11. 19. Check for obstructions at blower motor inlet and at plenum. Repair as necessary. If obstruction was found, go to HEATER OUTPUT TEMPERATURE CHECK . If obstruction was not found, go to next step. 20. With blower motor set to HI position, move temperature control from full hot position to full cold position. If change in airflow is present, go to next step. If change in airflow is not present, go to step 26. 21. Check for restrictions between heater case and instrument panel outlets. Repair as necessary. Go to HEATER OUTPUT TEMPERATURE CHECK . 22. Re-index cable or actuator. Inspect temperature valve, cables, and linkage adjustment. Repair or replace as necessary. After repairs, perform HEATER OUTPUT TEMPERATURE CHECK . 23. Check thermostat for proper installation. If thermostat is properly installed, go to step 27. If thermostat is not properly installed, go to next step. 24. Reinstall thermostat properly and go to step 13. 25. Reinstall hoses to proper positions and go to step 13. 26. Inspect the following components and repair as necessary: à   Temperature valve à   Control assembly à   Blower motor wiring harness Go to HEATER OUTPUT TEMPERATURE CHECK .

4/12/2010 ...

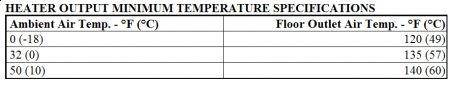

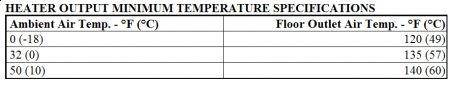

Temp check:

HEATER OUTPUT TEMPERATURE CHECK 1. Remove radiator cap when engine is sufficiently cool. Select heater (floor) mode, high temperature setting and high blower speed. Idle engine until coolant can be seen flowing in radiator. Install radiator cap. 2. When engine is warm, after about 20 minutes, drive vehicle at 30 MPH (48 km/h). Measure ambient air temperature and center vent outlet air temperature using a thermometer. If center vent air temperature exceeds minimum specification, heater output temperature is considered sufficient. See HEATER OUTPUT MINIMUM TEMPERATURE SPECIFICATIONS table.

Temp knob not working:

TEMPERATURE CONTROL INOPERATIVE 2000 Models 1. Perform BLOWER CONTROLS SYSTEM CHECK . Go to next step. 2. Check HVAC I fuse (10-amp) located in instrument panel fuse block. If fuse is blown, go to step 21 . If fuse is okay, go to next step. 3. Disconnect air temperature valve sensor and motor connector. Air temperature valve is located on top of HVAC assembly, on passenger's side. Turn ignition switch to ON position. Turn headlight switch to PARK position. Using DVOM connected to ground, probe air temperature valve motor harness connector terminal No. 8 (Light Blue wire). See WIRING DIAGRAMS . Move temperature control knob on A/C-heater control panel to hot (Red) and cold (Blue) positions. If voltage reading varies smoothly between zero and 12 volts, go to next step. If voltage reading does not vary smoothly between zero and 12 volts, go to step 9 . 4. Using DVOM connected to ground, measure voltage at air temperature valve motor harness connector terminal No. 10 (Brown wire). If battery voltage is indicated, go to next step. If battery voltage is not indicated, go to step 7 . 5. Using DVOM, measure voltage between air temperature valve motor harness connector terminals No. 10 (Brown wire) and No. 7 (Black wire). If battery voltage exists, go to next step. If battery voltage does not exist, go to step 8 . 6. Replace air temperature valve motor. See AIR TEMPERATURE VALVE ACTUATOR under REMOVAL & INSTALLATION. Perform BLOWER CONTROLS SYSTEM CHECK . 7. Repair open or high resistance in Brown wire between instrument panel fuse block HVAC I fuse and air temperature valve actuator. Perform BLOWER CONTROLS SYSTEM CHECK . 8. Repair open or high resistance in Black wire between air temperature valve actuator and ground G200. Ground G200 is located on firewall, left of instrument panel, near main harness connector to engine compartment. Perform BLOWER CONTROLS SYSTEM CHECK . 9. If voltage reading is at or near battery voltage, regardless of temperature control knob position, go to next step. If voltage reading is not at or near battery voltage, regardless of temperature control knob position, go to step 15 . 10. Disconnect A/C-heater control panel 3-pin harness connector C-3. Use a DVOM to measure voltage between A/C-heater control panel 3-pin harness connector C-3 terminals "A" (Brown wire) and "C" (Black wire). Turn ignition switch to ON position. Turn headlight switch to PARK position. If battery voltage is indicated, go to next step. If battery voltage is not indicated, go to step 12 . 11. Replace A/C-heater control panel. See A/C-HEATER CONTROL PANEL under REMOVAL & INSTALLATION. Perform BLOWER CONTROLS SYSTEM CHECK . 12. Move headlight switch to OFF position. If DVOM reading changes to battery voltage, go to next step. If DVOM reading does not change to battery voltage, go to step 14 . 13. Repair high resistance in Black wire between splice pack SP203 and ground G203. SP203 is strapped to instrument panel harness, in front of ashtray. Ground G203 is located in body harness, to right of instrument panel, on firewall below air inlet. Perform BLOWER CONTROLS SYSTEM CHECK . 14. Repair open or high resistance in Black wire between A/C-heater controller and splice pack SP203. Perform BLOWER CONTROLS SYSTEM CHECK . 15. If voltage reading is at or near zero voltage, regardless of temperature control knob position, go to next step. If voltage reading is not at or near zero voltage, regardless of temperature control knob position, return to step 10 . 16. Disconnect A/C-heater control panel 3-pin harness connector C-3. Using Connector Test Adapter Kit (J 35616-A), connect jumper wires between connector C-3 and A/C-heater control panel terminals. Using a DVOM connected to ground, backprobe A/C-heater control panel 3- pin connector C-3 terminal "B" (Light Blue wire). Turn ignition switch to ON position. Turn headlight switch to PARK position. Move temperature control knob on A/C-heater control panel to hot (Red) and cold (Blue) positions. If voltage reading varies smoothly between zero and 12 volts, go to next step. If voltage reading does not vary smoothly between zero and 12 volts, go to step 18 . 17. Repair open or high resistance in Light Blue wire between A/C-heater control panel and air temperature valve actuator. Perform BLOWER CONTROLS SYSTEM CHECK . 18. Use a DVOM to backprobe between A/C-heater control panel 3-pin connector C-3 terminals "A" (Brown wire) and "C" (Black wire). If battery voltage exists, go to step 23 . If battery voltage does not exist, go to next step. 19. Using a DVOM connected to ground, backprobe A/C-heater control panel 3-pin connector C-3 terminal "A" (Brown wire). If battery voltage is indicated, return to step 11 . If battery voltage is not indicated, return to step 7 . 20. Check HVAC 1 fuse No. 21. If fuse is okay, go to next step. If fuse is faulty, go to step 22 . 21. Repair short to ground in Brown wire between instrument panel fuse block and A/C-heater control panel harness connector C3 terminal "A". Perform BLOWER CONTROLS SYSTEM CHECK . 22. Repair open in Light Blue wire between instrument panel fuse block and ignition switch. After repair, perform BLOWER CONTROLS SYSTEM CHECK . 23. Disconnect jumper wire from connector C-3 terminal "B" (Light Blue wire). With jumper wire still connected to A/C-heater control panel, use a DVOM to measure voltage between jumper wire and ground. Disconnect air temperature valve actuator connector. Move temperature control knob on A/C-heater control panel to hot (Red) and cold (Blue) positions. If voltage reading varies smoothly between zero and 12 volts, go to next step. If voltage reading does not vary smoothly between zero and 12 volts, go to step 11 . 24. Repair short to ground in Light Blue wire between A/C-heater control panel harness connector C3 terminal "B" and air temperature valve actuator. After repair, perform BLOWER CONTROLS SYSTEM CHECK .

4/12/2010 ...

Saturday, October 3rd, 2020 AT 12:15 PM

(Merged)