Oh dont feel bad, you wouldnt believe some of the messes we get into here, I have spent months with certain people trying to explain even the simplest things to them, so youre all good, no worries.

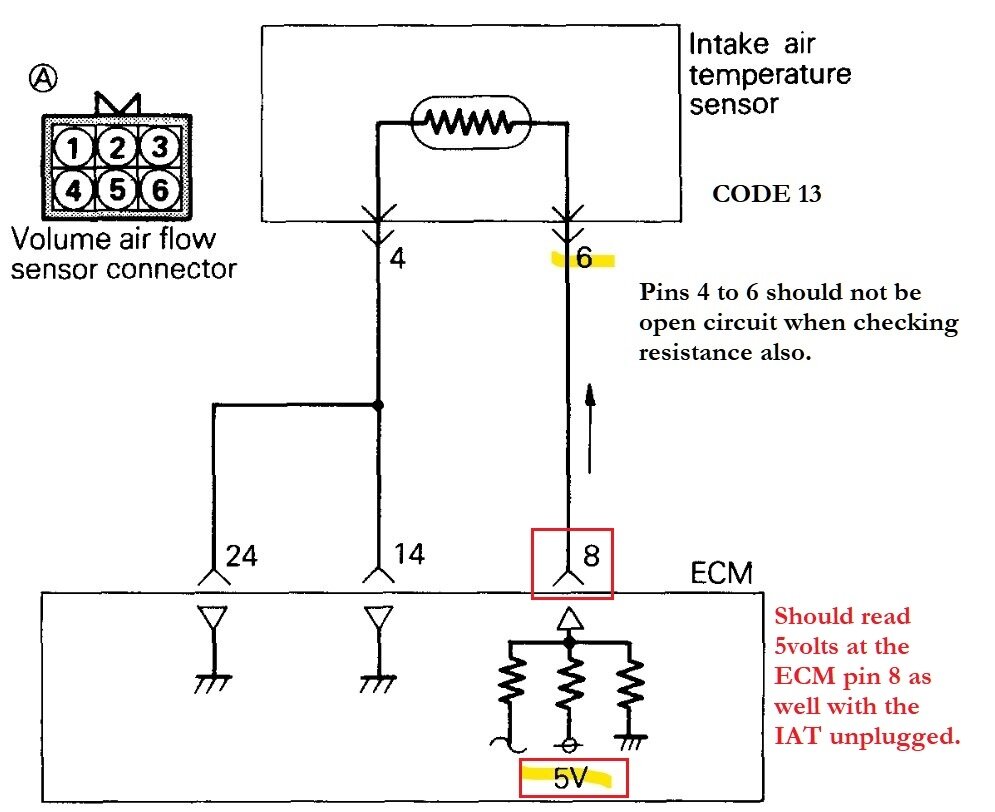

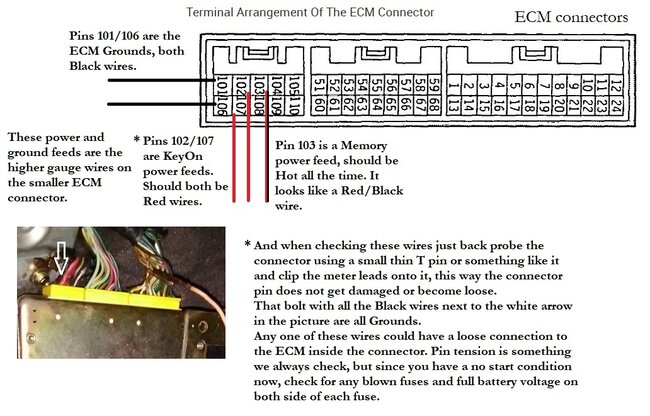

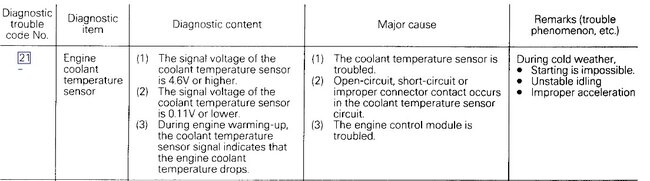

So as for your question on the two sensors possibly having their wiring shorted together, yes that can absolutely happen, to check that, unplug both sensors, and unplug the ECM connector they go to and just check pin 20 and pin 8 at the ECM connector for continuity between the two, there shouldnt be any reading between the two of them, with both ends

of the circuit open while unplugged they should read OL on the meter.

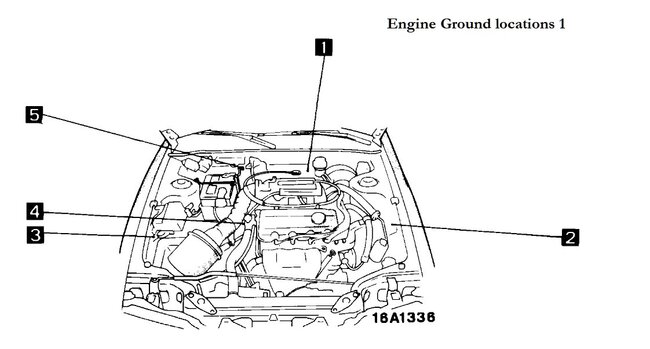

Another test you can do is with them both still unplugged, check for continuity to ground (Battery Negative) on either wire, there should also be no reading from that test. If you read anything, the wires can be shorted to ground somewhere, its common to find wires melted together at location where they might be touching the exhaust or a contact location where they have been rubbing on metal over the years and they short out that way.

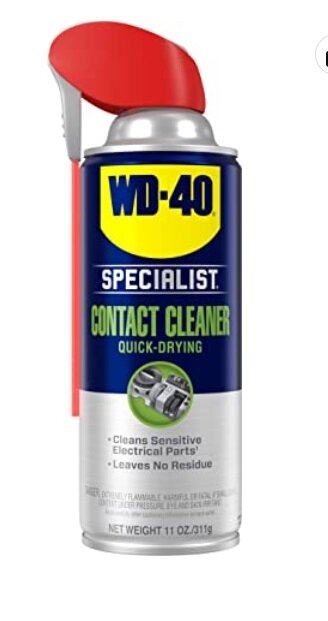

A corroded connector can also short circuits together, if water or some other liquid has gotten into something like a bulk connector, in that case you will find a bunch of green or white crusty corrosion inside the pins of the connector. Even a pin hole of a wire can corrode inside, and the corrosion can just grow inside the wire insulation breaking the copper strains, those are difficult to find because you cant actually see the corrosion.

So following the wiring in the harness from a sensor will sometimes lead you to a location where the wiring is just a complete mess.

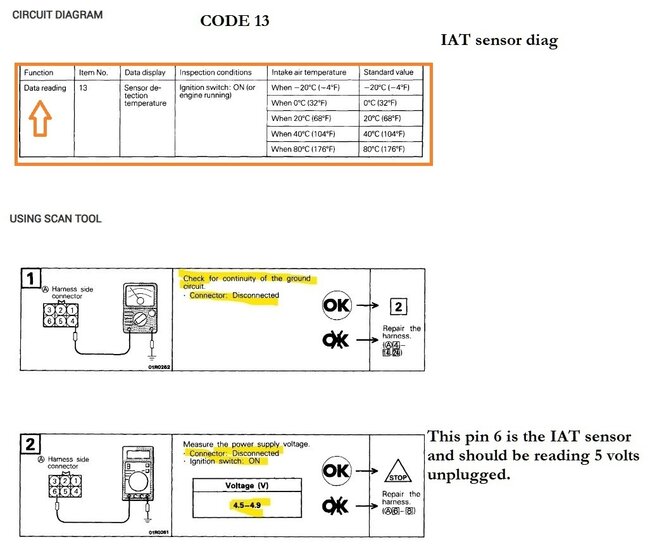

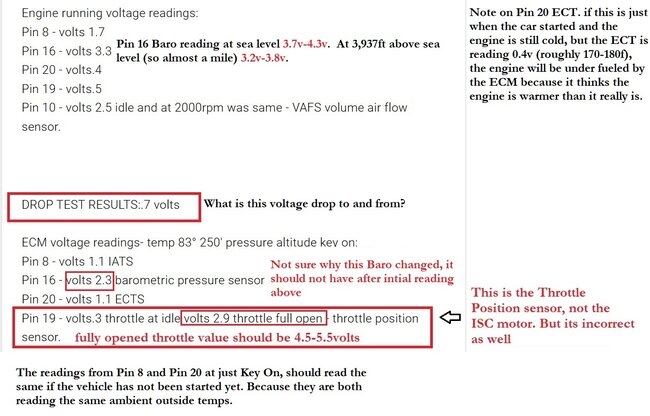

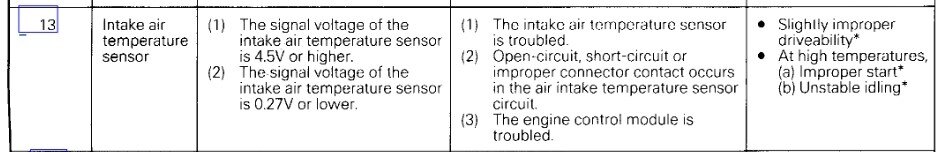

From your readings it sounds like Pin 13 & 23 are a different voltage regulator inside the ECM and pin 8 and 20 share a different 5volt regulator, or most likely you would be reading the same 3.8 volts on 8 and 20 as well.

The best thing for you to do if the vehicle is not going to be driven for a while is unhook the negative battery cable, that will prevent it from draining as fast.

When a battery goes bad, it can be the result of either being tightened down too much, in which the cells inside the battery actually get crushed and shorted together, many people tighten the battery hold down too much, you can tell when you see a battery that has the top squished down and the sides are bulging out. That happens a lot when places like auto parts stores replace the battery for a customer and over tighten it.

And batteries also just age, and become sulfated inside which also shorts out the cells inside, there are 6 cells in a 12v lead acid battery, 2volts per cell, so when 2 cells get shorted together, the battery can no longer be fully charged or hold a charge.

A bad battery will also eventually take the Alternator out, due to it being overworked trying to charge a bad battery.

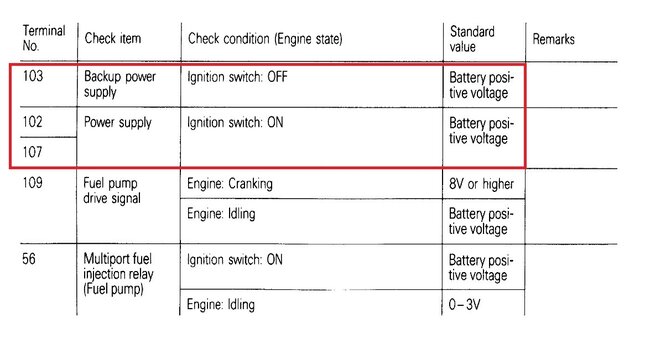

With that said, the 3.8 volts is an issue, if you do not find a wiring problem, we will have to check the ECM powers and grounds for any voltage drop while the vehicle is running with some electrical loads on.

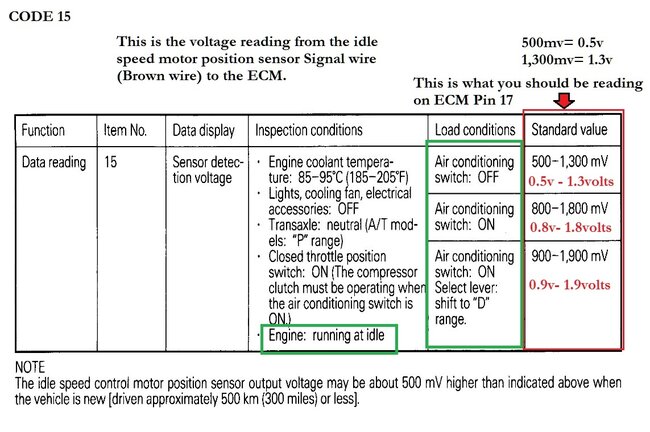

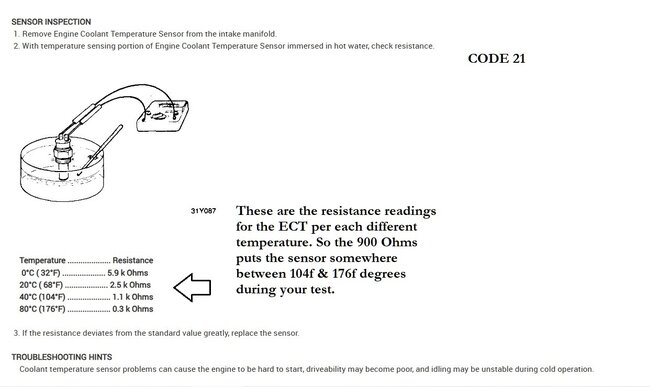

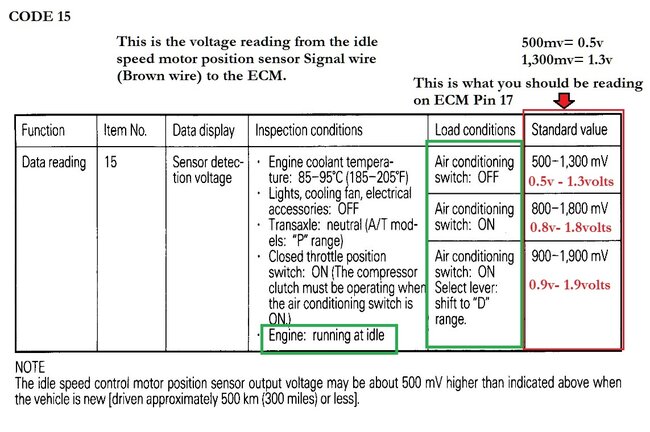

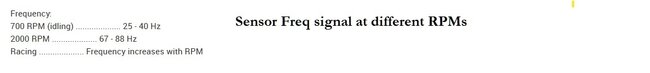

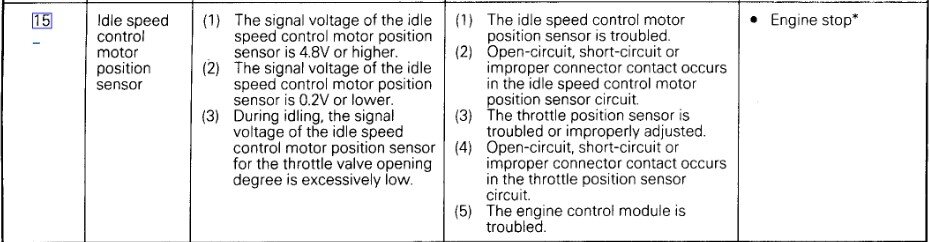

The ISC motor sensor gets its 5volts from pins 13 and 23, and the resistance reading of the sensor was within spec, so these are the voltage values you should expect on ECM pin 17 while its running, I know I posted this already, but something else to recheck since we seem to be getting to the bottom of seeing what the causes of some of these codes are. It looks like there are just possibly multiple problems which is not surprising.

Look for rodents nests too, vehicles not driven much seem to always have more rodent damage to wiring harnesses. Ive seen so many those. Especially under the passenger side dash where the blower motor is, they love to make nests in those areas, and they eat the insulation on the wires because it contains a chemical they like the taste of. Pretty gross.

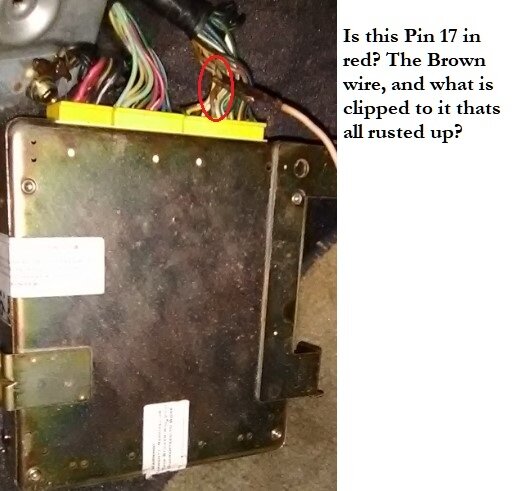

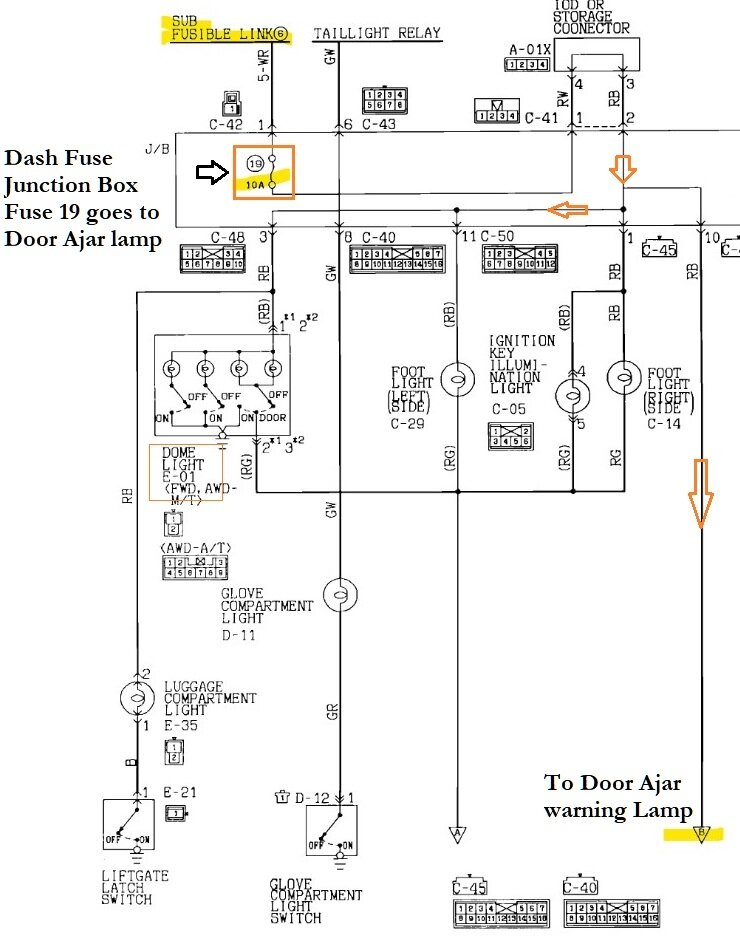

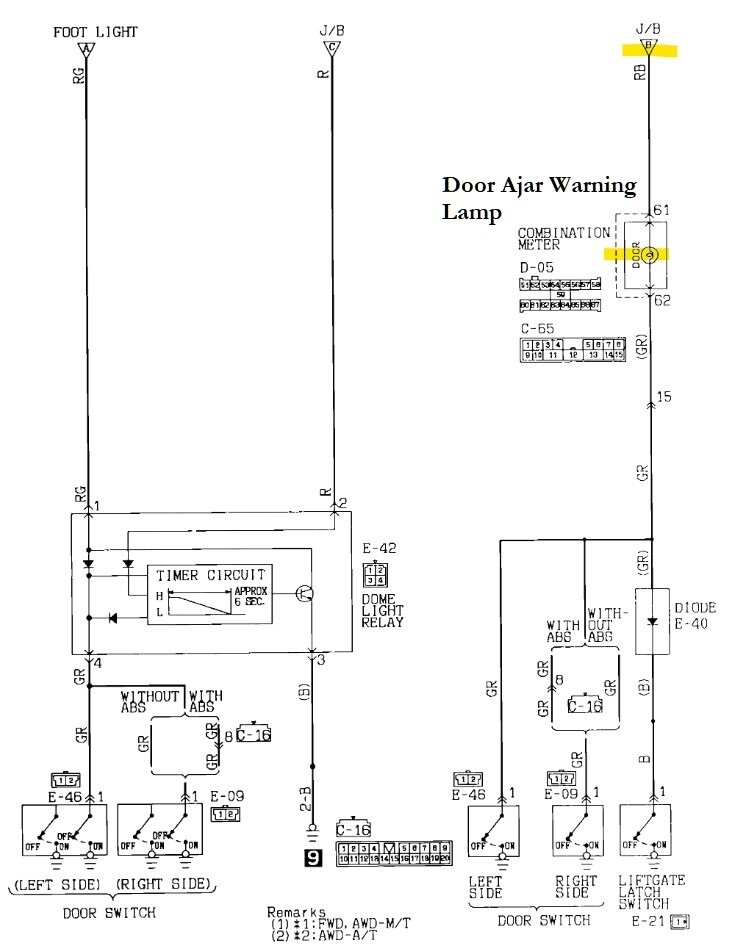

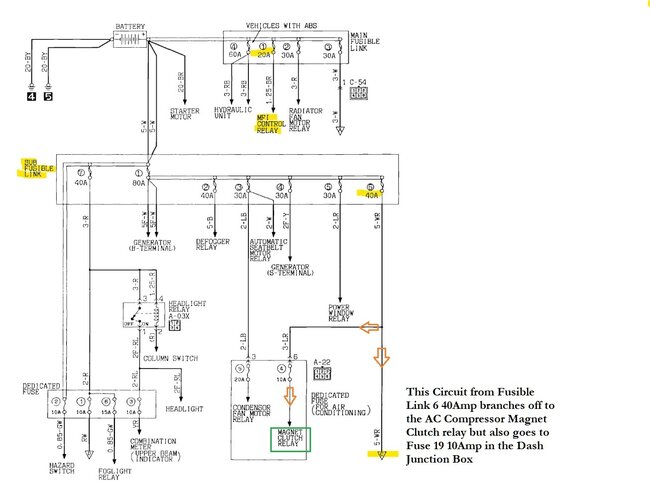

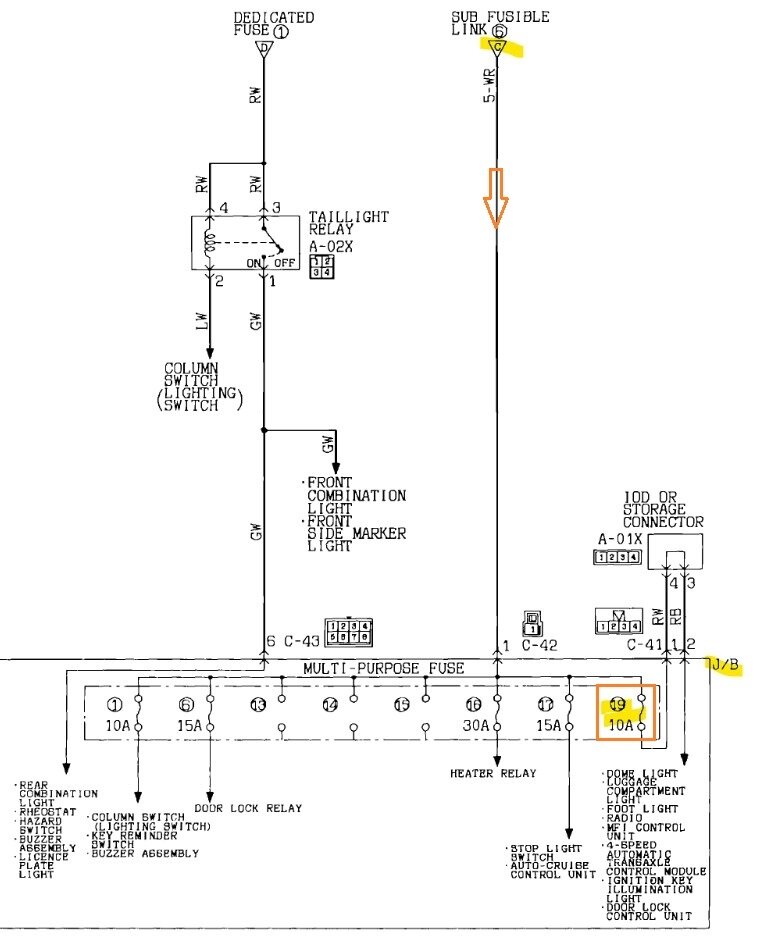

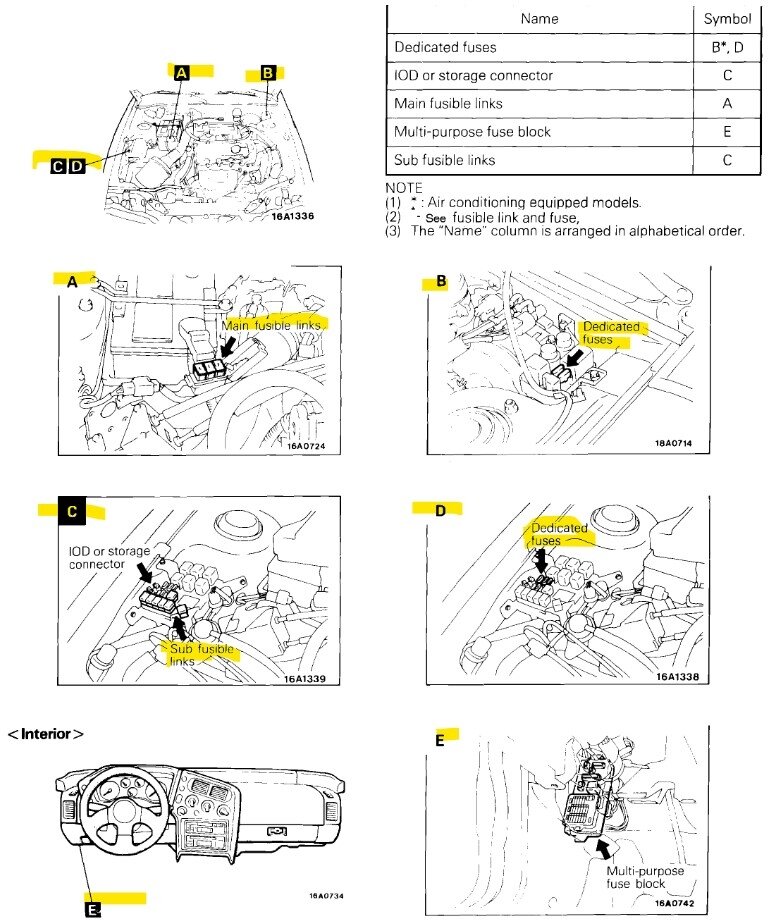

Image (Click to make bigger)

Saturday, October 5th, 2024 AT 5:15 PM