Hello,

This is common when the PCM goes out here is the replacement and reprogramming procedures with diagrams below to show you how.

Engine Control Module Programming and Setup

The following service procedures require either a programming or a setup event performed for a complete repair.

ECM Replacement

If the engine control module (ECM) is replaced, the following procedures must be performed:

1. ECM Reprogramming-Refer to Service Programming System (SPS) (See: Vehicle > Programming and Relearning).

2. The CKP System Variation Learn-Refer to the following:

* Crankshaft Position System Variation Learn (See: Crankshaft Position Sensor > Removal and Replacement)for the 2.4L engine

* Crankshaft Position System Variation Learn (See: Crankshaft Position Sensor > Removal and Replacement)for the 3.5L engine

* Crankshaft Position System Variation Learn (See: Crankshaft Position Sensor > Removal and Replacement)for the 3.6L engine

* Crankshaft Position System Variation Learn (See: Crankshaft Position Sensor > Removal and Replacement)for the 3.9L engine

3. Engine Oil Life Remaining-When available, use a scan tool to reset the Engine Oil Life Remaining back to the original percentage recorded before the module was replaced.

4. Transmission Fluid Life Remaining-When available, use the scan tool to reset the Transmission Fluid Life Remaining back to the original percentage recorded before the module was replaced.

5. Theft Deterrent-Refer to Immobilizer System Component Programming (See: Vehicle > Programming and Relearning).

ECM Reprogramming

* If the ECM needs to be reprogrammed, refer to Service Programming System (SPS) (See: Vehicle > Programming and Relearning).

* Engine Oil Life Remaining-When available, use a scan tool to reset the Engine Oil Life Remaining back to the original percentage recorded before the module was reprogrammed.

Important: After programming, perform the following to avoid future misdiagnosis:

* Turn the ignition OFF for 30 seconds.

* Turn the ignition ON with the engine OFF.

* Use the scan tool in order to retrieve history DTCs from all modules.

* Clear all history DTCs.

Setup for Component Replacement

The replacement of some components will require a setup procedure for complete repair.

If any of the following components are replaced, the CKP Variation Learn Procedure must be performed:

* Engine replacement

* Any engine repair that disturbs the CKP sensor or its relationship with the crankshaft reluctor wheel

* CKP sensor

Refer to the following:

* Crankshaft Position System Variation Learn (See: Crankshaft Position Sensor > Removal and Replacement)for the 2.4L engine

* Crankshaft Position System Variation Learn (See: Crankshaft Position Sensor > Removal and Replacement)for the 3.5L engine

* Crankshaft Position System Variation Learn (See: Crankshaft Position Sensor > Removal and Replacement)for the 3.6L engine

* Crankshaft Position System Variation Learn (See: Crankshaft Position Sensor > Removal and Replacement)for the 3.9L engine

Crankshaft Position System Variation Learn

Note: The Crankshaft Position (CKP) system variation learn procedure is also required when the following service procedures have been performed, regardless of whether DTC P0315 is set:

* An engine replacement

* A engine control module (ECM) replacement

* A crankshaft balancer replacement

* A crankshaft replacement

* A CKP sensor replacement

* Any engine repairs which disturb the crankshaft to CKP sensor relationship.

Note: The ECM monitors certain component signals to determine if all the conditions are met to continue with the CKP System Variation Learn Procedure. The scan tool only displays the condition that inhibits the procedure. The scan tool displays the signals of the following components:

* CKP sensors activity-If there is a CKP sensor condition, refer to the applicable DTC that set.

* Camshaft position (CMP) signal activity-If there is a CMP signal condition, refer to the applicable DTC that set.

* Engine coolant temperature (ECT)-If the engine coolant temperature is not warm enough, idle the engine until the engine coolant temperature reaches the correct temperature.

1. Install a scan tool.

2. Monitor the ECM for DTCs with a scan tool. If other DTCs are set, except DTC P0315, refer to Diagnostic Trouble Code (DTC) List - Vehicle (See: A L L Diagnostic Trouble Codes ( DTC ) > Diagnostic Trouble Code Descriptions) for the applicable DTC that set.

3. With a scan tool, select the CKP System Variation Learn Procedure and perform the following:

1. Block drive wheels.

2. Set parking brake.

3. DO NOT apply brake pedal.

4. Cycle ignition from OFF to ON.

5. Apply and hold brake pedal for the duration of the procedure.

6. Start and idle engine.

7. Turn the air conditioning (A/C) OFF.

8. The vehicle must remain in Park or Neutral.

Note: While the learn procedure is in progress, release the throttle immediately when the engine starts to decelerate. The engine control is returned to the operator and the engine responds to throttle position after the learn procedure is complete.

9. Accelerate to wide open throttle (WOT) and release when the fuel cut-off occurs.

4. The scan tool displays Learn Status: Learned this Ignition. If the scan tool indicates that DTC P0315 ran and passed, the CKP variation learn procedure is complete. If the scan tool indicates DTC P0315 failed or did not run, or another DTC is present, refer to Diagnostic Trouble Code (DTC) List - Vehicle (See: A L L Diagnostic Trouble Codes ( DTC ) > Diagnostic Trouble Code Descriptions) and perform the appropriate diagnostic procedure.

5. Turn OFF the ignition for 30 seconds after the learn procedure is completed successfully in order to store the CKP system variation values in the ECM memory.

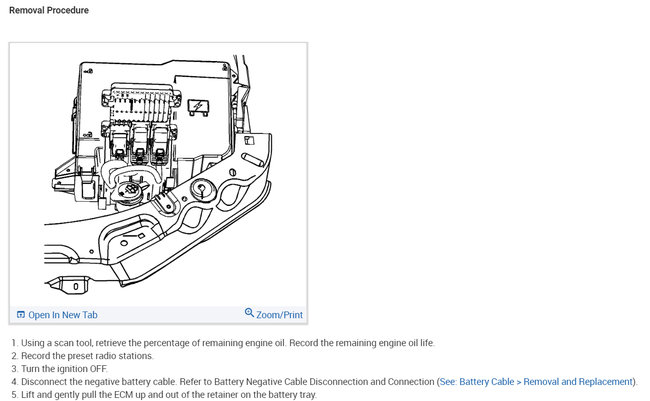

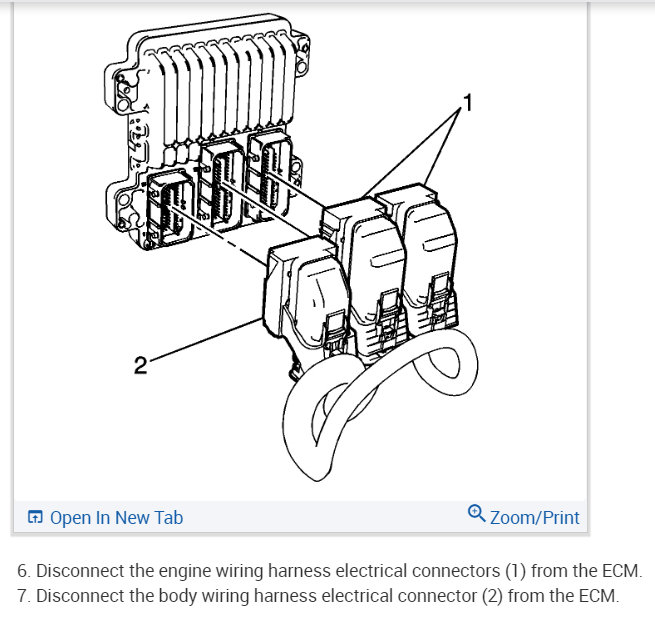

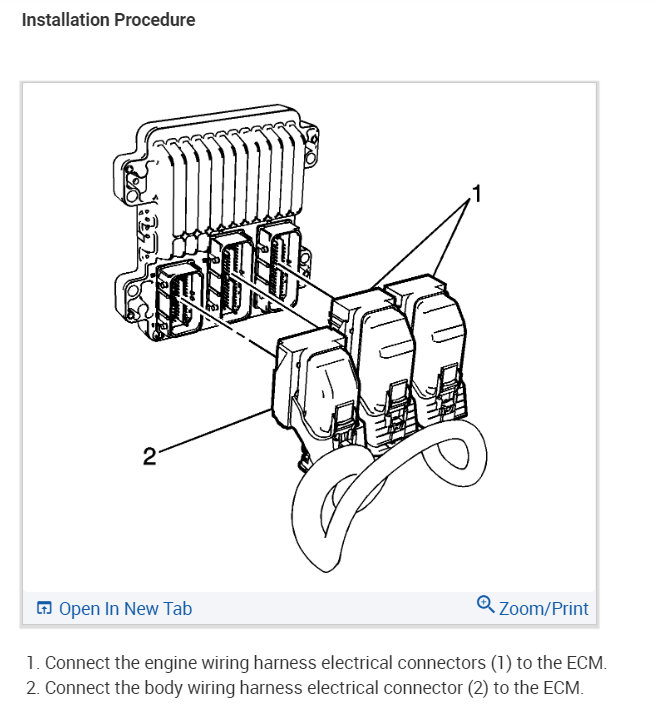

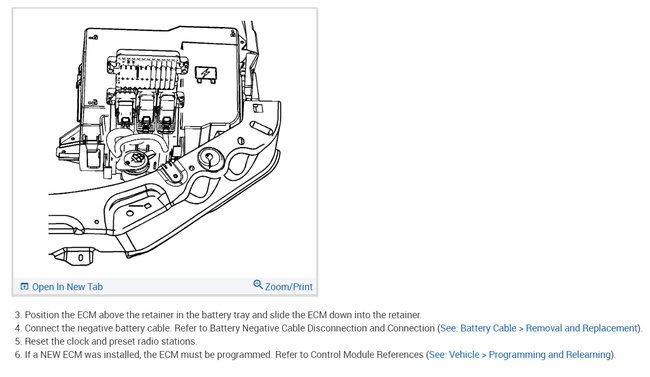

Check out the diagrams (below). Please let us know what happens.

Images (Click to make bigger)

SPONSORED LINKS

Monday, December 9th, 2019 AT 10:49 AM