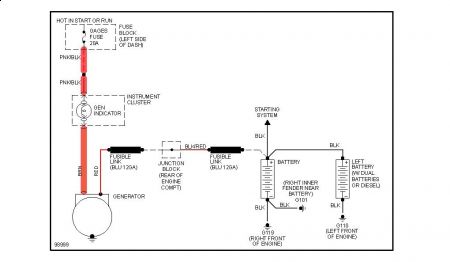

We should be able to figure this out. When there is only one small wire plugged in at the rear/side of the generator, current comes through the "gauges" fuse, to the instrument cluster, through the "battery" warning light, then goes through the brown wire at the generator. Roughly 10 volts is dropped across the light, so it turns on, and the 2 volts that is left at the generator is the signal for the internal voltage regulator to turn on and start doing its thing. Once the engine is running and the belt is spinning the generator's field winding, it produces its output current. The voltage regulator sees that, then it sends 12 volts back out on that brown wire. With 12 volts on that side of the light bulb, and 12 volts from the fuse on the other side, the difference is 0 volts, so the bulb turns off.

The first step in testing the system is to observe if the warning light turns on when the ignition switch is turned on. You did that. That proves everything is okay up to the bulb. Where things fell apart is when you unplugged the wire at the generator. That will break the circuit, current flow stops, and the bulb should turn off. The fact your bulb stayed on indicates current is still flowing through it, and to do that, it has to find a path back to ground, then to the battery's negative cable.

It sounds like you are describing an intermittent problem that only acts up at times. A confusing part of this system is the 2 volts on the brown wire tells the voltage regulator to turn on, but on these earlier systems, there is nothing to tell it to turn off. If the brown wire becomes grounded while you are driving, the warning light will turn on full brightness, but since the generator is up and running, it will continue to do so.

I should stop for a minute and explain the fundamental principle of "generating a current mechanically". Three things are required to do that. You need a piece of wire, a magnetic field, and most importantly, movement between them. Any time a magnetic field moves through a wire, it "induces" a voltage which causes current to want to flow. To make it much more efficient, we use many coils of wire for the wire, an easily-adjustable electromagnet to produce the magnetic field, and that is the part that spins thanks to the drive belt. That's the movement.

The voltage regulator controls how much current flows through the spinning field winding. It switches itself on when a couple of volts shows up on the brown wire, then, some of the generator's output current is used to keep the regulator powered up. As long as the engine keeps on spinning the generator, output current is produced, that keeps the voltage regulator powered up, and the regulator keeps the field winding powered up, and that keeps the generator producing output current, and on and on. There is no way designed in to let you switch that process off. The only thing that can stop it is turning the engine off. Once there is no movement between the spinning field winding and the stationary "stator" winding, output current ceases to be produced, and the system turns off.

I shared all of that magnificent story to point out the brown wire serves no purpose once the system is up and running as long as it is working properly. When an internal defect inside the generator develops, the voltage regulator stops putting 12 volts on the brown wire. There is still 12 volts on the fuse side of the warning light, but with no opposing voltage on the regulator side, the light turns on.

Ignition switch on/engine not running at this point. All of this light bulb operation works as designed when that brown wire is connected to the voltage regulator. The proof of that is the light turns off when you unplug the wire. Yours, however, does not go out. That means the brown wire has to be grounded someplace to the engine or an unpainted surface on the body sheet metal. If that short occurs before you start the engine, the voltage regulator will only see 0 volts on the brown wire, so it will not turn on. More on that in a moment. You'll see the "battery" light stays on, and system voltage is low. Lights will be dim and the heater and wiper motors will run slower than normal. If engine vibration makes that short go away, even for an instant, the normal 2 volts will appear on the brown wire, the voltage regulator will turn on, system voltage will rise to a normal 13.75 to 14.75 volts, and it will continue to work normally until you stop the engine, even if the short comes back and the warning light turns back on.

Now for the clinkers in my explanation. There are some variations in voltage regulators for some years and some applications. They used to turn on the warning light when the system stopped working, but now there are some that will turn the light on when an under-charge or an over-charge condition exists.

Next, all rotating field windings consist of a long wire wrapped around an iron core. It is common for that core to become magnetized over time. That "residual magnetism" can be strong enough to get the system started when there is a problem with the brown wire. We used to see this a lot with GM's much better 1986 and older system.

Finally, to diagnose this, the ignition switch must be off, and if this is an intermittent problem, it has to be acting up at the time you take the measurements. Unplug the brown wire, then use an ohm meter to test if that wire is indeed grounded. Here are links to some related articles:

https://www.2carpros.com/articles/how-to-use-a-voltmeter

https://www.2carpros.com/articles/how-to-check-wiring

The first article shows testing with an auto-ranging meter. If yours has a switch for selecting the range, use the lowest one for ohms, typically a 200 ohm range. If you need help with using the meter. let me know and I'll describe it for you. If that wire is grounded, it would normally measure 0 ohms, but be aware there is always a little resistance in the meter's leads, so expect to see around 2 to 5 ohms. You want to see an open circuit. Different meters have different ways of showing that. All you have to do is see what your meter shows when the probes are not connected to anything.

If you find a very low reading, prop the meter so you don't have to hold onto it, then work your way along the wire harness and flex or move it to see if the short goes away. You will rarely find the problem inside a straight length of "convoluted tubing" that is wrapped around the harness. The common places to find a grounded wire are where the harness is draped over the sharp edge of a metal bracket, or where it has fallen down onto hot engine parts. That brown wire runs behind the dash to the instrument cluster. The most common failure there is from someone adding accessories under the dash and they accidentally pinch a wire under a mounting bracket. The least common place to find this problem is in the "bulkhead" connector. That's the large plug on the firewall. Sometimes water drips down onto it and forms corrosion between adjacent terminals.

Now that I shared all that wondrous story, there is an even easier way you can approach this. Instead of using the ohm meter, have a helper watch the "battery" light while the ignition switch is on and the connector is unplugged at the generator. Your symptom is the light is still on. Now wiggle and move the harness around. The light will flicker off when you do something to make the short go away. That will tell you you're in the right area.

Thursday, September 3rd, 2020 AT 6:27 PM

(Merged)