I'm trying to picture the wiring diagram and everything I've seen before has battery voltage, (lets say 14.0 volts) applied to the resistor, then current flows through it to the coil primary where the voltage will be lower, through the coil where we would like it to be real low, then through the module which takes the place of the breaker points. It's a switch.

If you're measuring that 2.8 volts right after the resistor where it connects to the coil, that may be fine. 2.8 volts across the coil doesn't sound like much, and not enough to build a nice magnetic field, but that isn't done with voltage. It's done with current. Doing the math, if you have 14.0 volts on one side of the resistor and 2.8 volts on the other, that's a drop of 11.2 volts. Using Ohm's Law, current equals voltage divided by resistance. 11.2 volts divided by 1.1 ohms equals 10.18 amps. That's a pile. Knowing the current we could also calculate the resistance of the coil and module but that is irrelevant. If that was a breaker point system the contacts would be red hot.

If you're measuring that 2.8 volts on the control side of the coil that connects to the module, not where the resistor is connected, we'd have to include the coil's resistance which is typically about 1 ohm or a little less. Lets say the resistor and coil together totaled 2.0 ohms. Current would be 11.2 volts divided by 2 ohms equals 5.6 amps. That's still a real lot but not quite as dramatic as before.

Next, you have to remember that if that 2.8 volts was measured with the engine running, the module turns the current flow off when it wants a spark to occur. That 0.0 amps gives the resistor, coil and module time to cool down until the module turns back on to build the magnetic field for the next spark. If that 2.8 volts was with the engine not running, the module is keeping the current flowing and it's waiting for a signal to turn the current off and make a spark. I could see 2.8 volts at the module but the 5 amps is a lot to expect from that sad little switching transistor in it. Current makes heat and transistors hate heat.

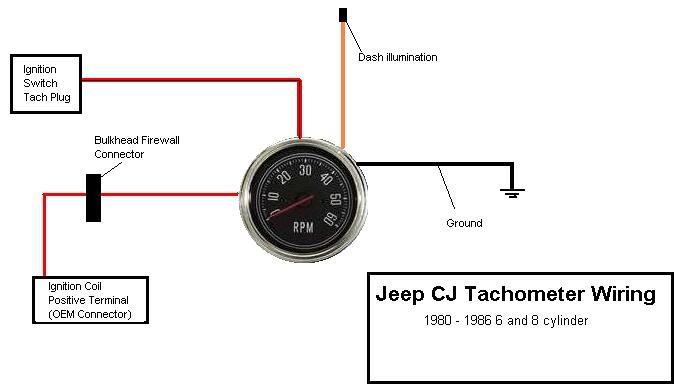

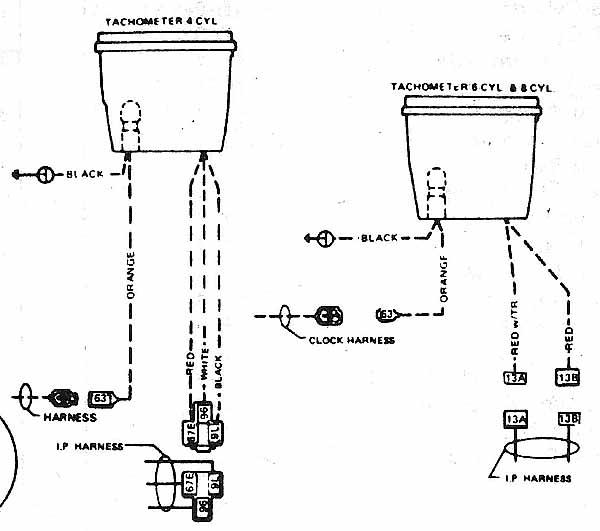

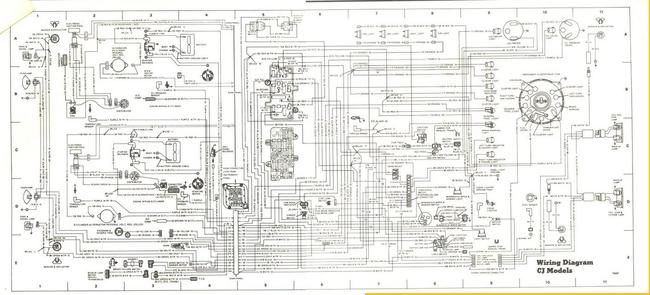

I wish I had the exact diagram to look at. Without one is like trying to drive cross-country with no road map.

Was this helpful?

Yes

No

Tuesday, May 7th, 2013 AT 7:59 PM