I don't know if you want this, but here are the directions for replacement. All attached pictures correlate with these directions. Plus, the labor for this job shouldn't exceed 6.0 hours.

__________

TIMING CHAIN REMOVAL AND INSTALLATION

CHAIN AND SPROCKETS-TIMING

REMOVAL

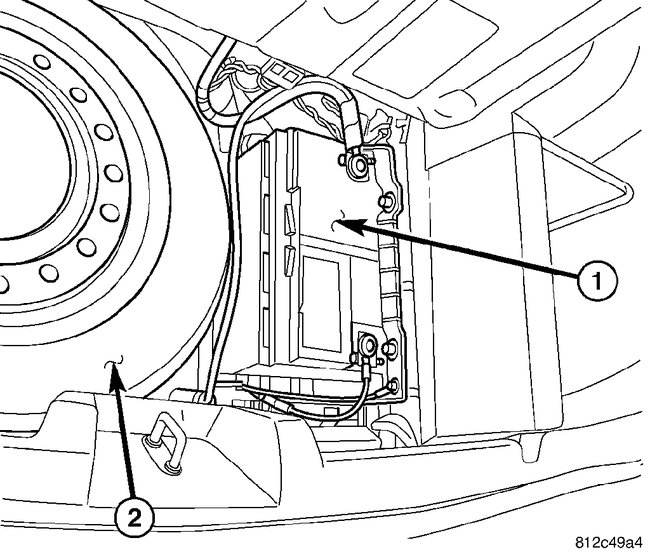

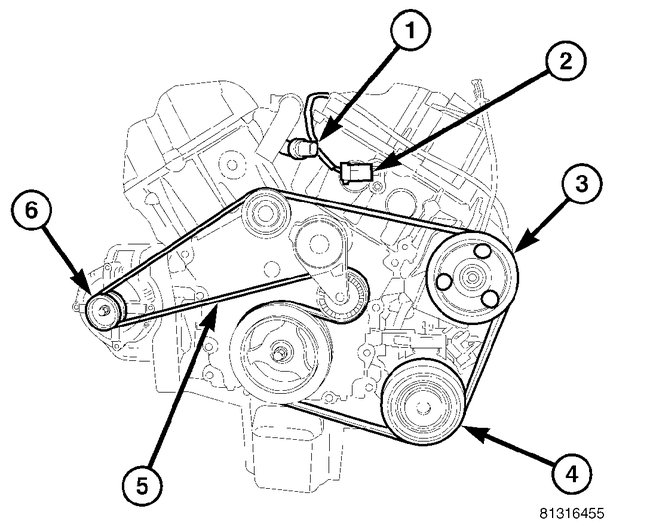

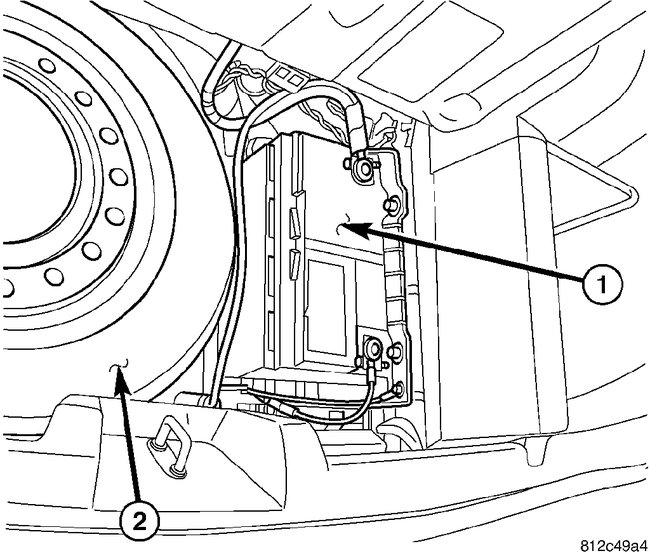

1. Disconnect negative battery (1)cable.

2. Drain cooling system.

3. Remove upper intake manifold.

4. Remove cylinder head covers, crankshaft vibration damper, and timing chain cover.

CAUTION: When aligning timing marks, always rotate engine by turning the crankshaft. Failure to do so will result in valve and/or piston damage.

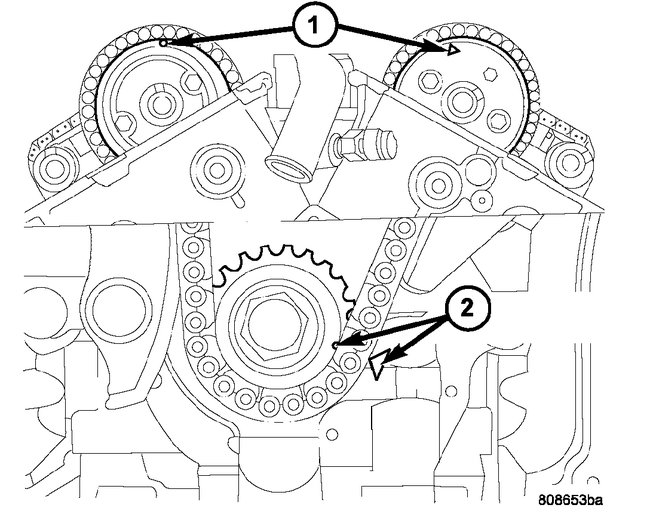

5. Align crankshaft sprocket timing mark to mark on oil pump housing (2). The mark on oil pump housing is 60° ATDC of #1 cylinder.

CAUTION: When the timing chain is removed and the cylinder heads are still installed, DO NOT rotate the camshafts or crankshaft without first locating the proper crankshaft position. Failure to do so will result in valve and/or piston damage.

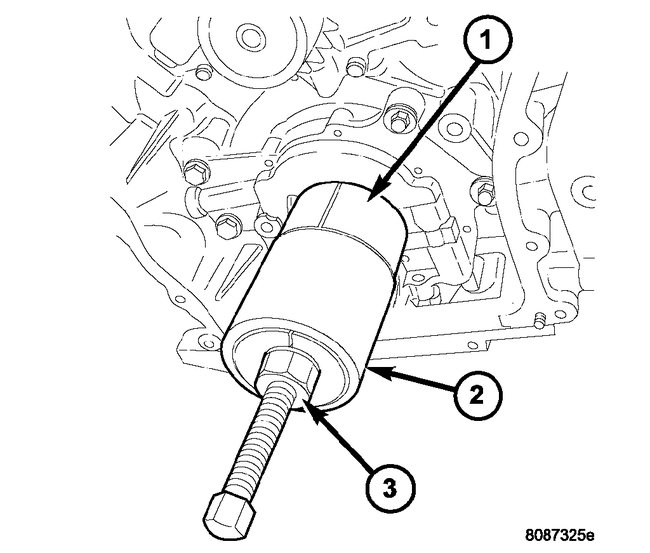

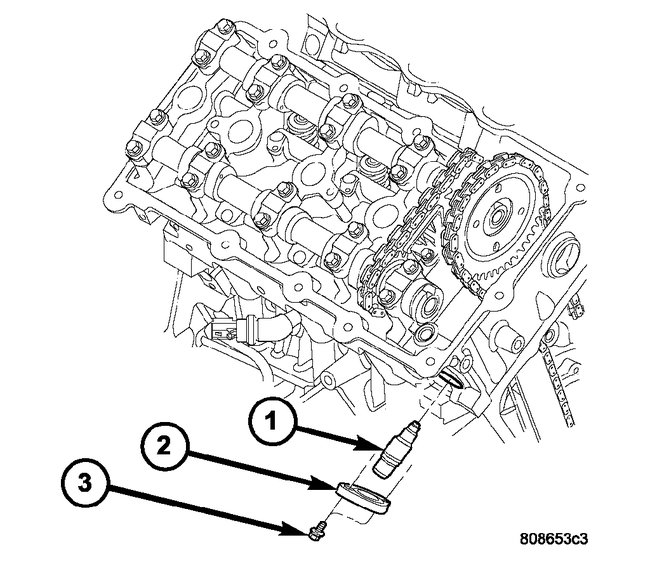

6. Remove primary timing chain tensioner retainer cap (2) and tensioner (1) from right cylinder head.

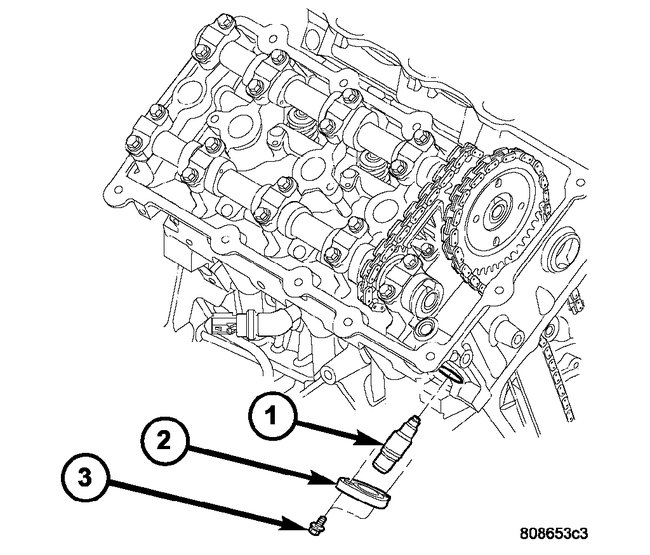

7. Disconnect and remove camshaft position sensor (4) from left cylinder head.

8. Remove timing chain guide access plugs (3) from cylinder heads.

NOTE: When camshaft sprocket bolts are removed, the camshafts will rotate in a clockwise direction.

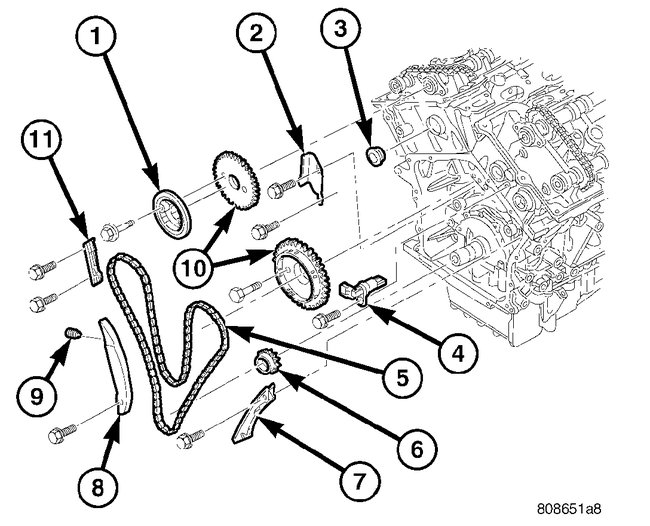

9. Starting with the right camshaft sprocket, remove the sprocket attaching bolts. Remove camshaft damper (1) (if equipped) and sprocket.

10. Remove left side camshaft sprocket attaching bolts and remove sprocket.

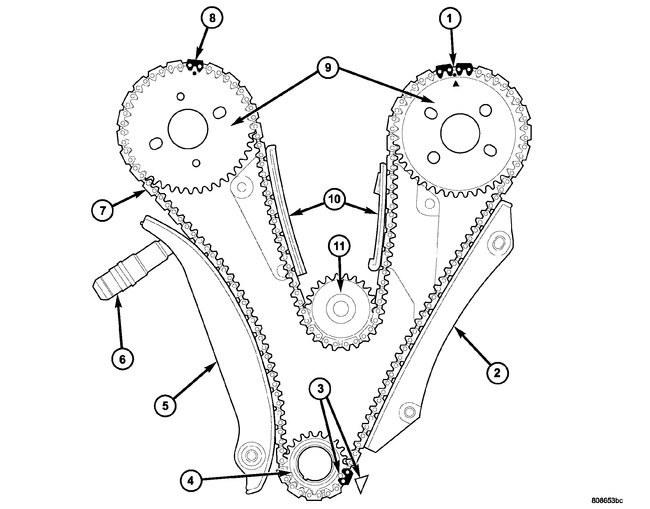

11. Remove lower chain guide (7) and tensioner arm (8).

12. Remove the primary timing chain (5).

REMOVAL - CRANKSHAFT SPROCKET

1. Remove primary timing chain.

CAUTION: Use care not to turn crankshaft while removing crankshaft sprocket, as damage to valves and or pistons could occur.

2. Remove crankshaft sprocket by first installing the crankshaft damper bolt. Apply grease or equivalent to damper bolt head and position Special Tools 5048-1(3), 5048-6 (2), and 8539 (1) on sprocket and crankshaft nose. Remove sprocket using care not to rotate the crankshaft.

INSTALLATION

TIMING CHAIN

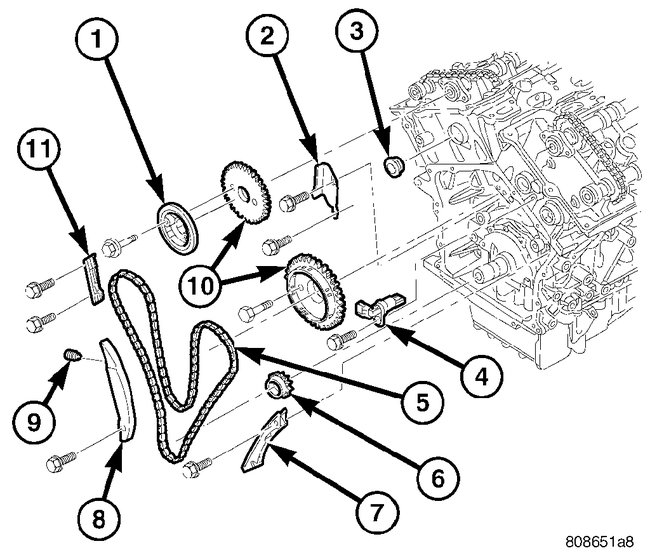

1. Inspect all sprockets (4, 9, 11) and chain guides (2, 5, 10). Replace if worn.

2. Install crankshaft sprocket.

3. If removed, install right and left side short chain guides (11). Tighten attaching bolts to 28 Nm (250 inch lbs.).

4. Align crankshaft sprocket timing mark to the mark on oil pump housing(3).

NOTE: Lubricate timing chain and guides with engine oil before installation.

5. Place left side primary chain sprocket onto the chain so that the timing mark is located in-between the two (plated) timing links (1).

6. Lower the primary chain with left side sprocket through the left cylinder head opening.

NOTE: The camshaft sprockets can be allowed to float on the camshaft hub during installation.

7. Loosely position left side camshaft sprocket over camshaft hub.

8. Align timing (plated) link to the crankshaft sprocket timing mark (3).

9. Position primary chain onto water pump drive sprocket (10).

10. Align right camshaft sprocket timing mark to the timing (plated) link on the timing chain (8) and loosely position over camshaft hub.

11. Verify that all chain timing (plated) links are properly aligned to the timing marks on all sprockets.

12. Install left side lower chain guide (2) and tensioner arm (5). Tighten attaching bolts to 28 Nm (250 inch lbs.).

NOTE: Inspect O-ring on chain guide access plugs before installing. Replace O-ring as necessary.

13. Install chain guide access plugs to cylinder heads. Tighten plugs to 20 Nm (15 ft. Lbs.).

NOTE: To reset the primary timing chain tensioner, engine oil will first need to be purged from the tensioner.

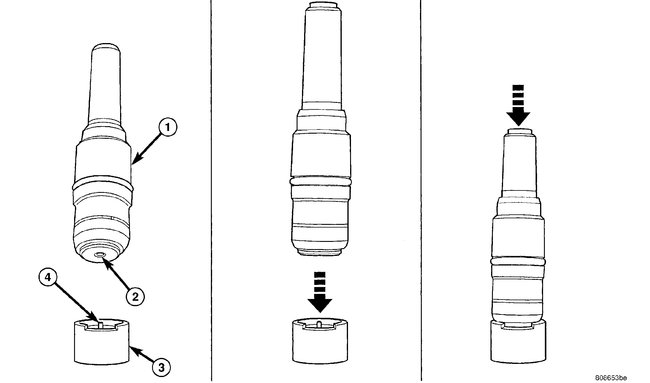

14. Purge oil from timing chain tensioner using the following procedure:

a. Place the check ball (2) end of tensioner into the shallow end of Special Tool 8186 (3).

B. Using hand pressure, slowly depress tensioner until oil is purged from tensioner.

15. Reset timing chain tensioner using the following procedure: a. Position cylinder plunger (4) into the deeper end of Special Tool 8186 (3). B. Apply a downward force until tensioner is reset.

NOTE: If oil was not first purged from the tensioner, use slight finger pressure to assist the center arm pin of Special Tool 8186 to unseat the tensioner's check ball.

CAUTION: Ensure the tensioner is properly reset. The tensioner body (4) must bottom against the top edge of Special Tool 8186 (3). Failure to properly perform the resetting procedure may cause tensioner jamming.

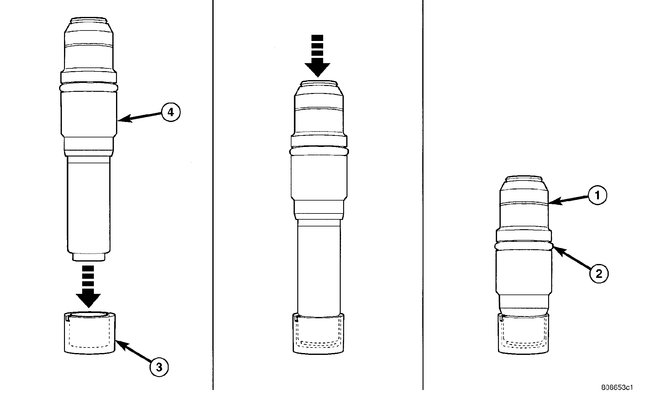

NOTE: Inspect the tensioner O-ring (2) for nicks or cuts and make sure the snap ring (1) is correctly installed, replace as necessary.

16. Install the reset chain tensioner (1) into the right cylinder head.

17. Position tensioner retaining plate (2) and tighten bolts (1) to 12 Nm (105 inch lbs.).

18. Starting at the right cylinder bank, first position the camshaft damper (1) (if equipped) on camshaft hub, then insert a 3/8" square drive extension with a breaker bar into intake camshaft drive hub. Rotate camshaft until the camshaft hub aligns to the camshaft sprocket and damper attaching holes. Install the sprocket attaching bolts and tighten to 28 Nm (250 inch lbs.).

19. Turn the left side camshaft by inserting a 3/8" square drive extension with a breaker bar into intake camshaft drive hub and rotate camshaft until the sprocket attaching bolts can be installed. Tighten sprocket bolts to 28 Nm (250 inch lbs.).

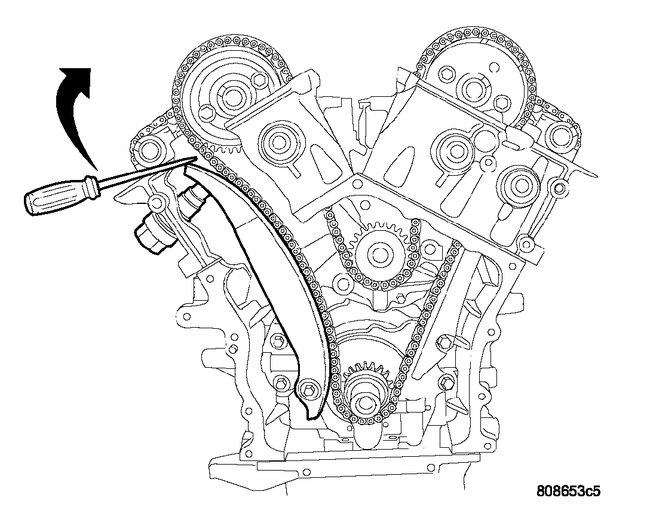

20. Rotate engine slightly clockwise to remove timing chain slack, if necessary.

21. Activate the timing chain tensioner by using a flat bladed pry tool to gently pry tensioner arm towards the tensioner slightly. Then release the tensioner arm. Verify the tensioner is activated (extends).

22. Install camshaft position sensor (2) and connect electrical connector.

23. Install the timing chain cover, crankshaft vibration damper, and cylinder head covers.

24. Install upper intake manifold.

NOTE: After installation of a reset tensioner, engine noise will occur after initial start-up. This noise will normally disappear within 5-10 seconds.

25. Fill cooling system.

26. Connect negative battery (1) cable.

INSTALLATION - CRANKSHAFT SPROCKET

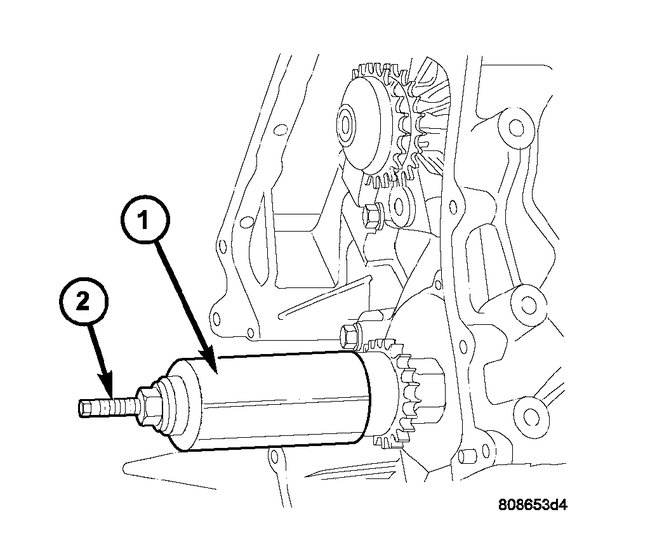

1. Install crankshaft sprocket using Special Tools 6780-1(1) and 8179 (2) until sprocket bottoms against crankshaft step flange. Use care not to rotate crankshaft.

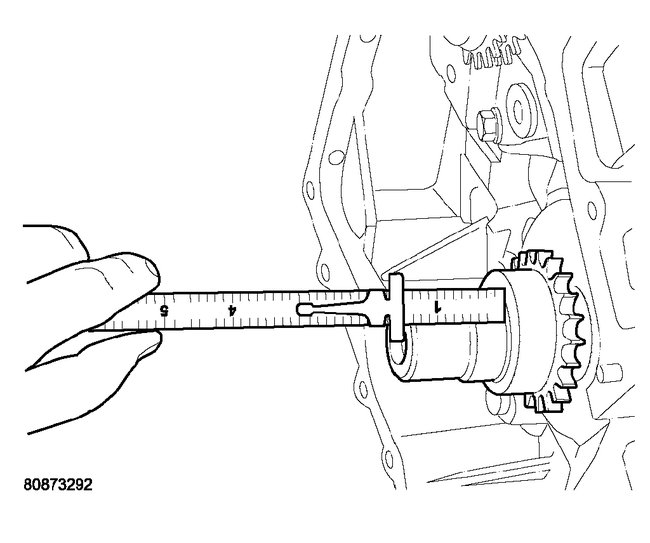

2. Verify that crankshaft sprocket is installed to proper depth by measuring from sprocket outer face to end of crankshaft. Measurement should read: 39.05 ± 0.50 mm (1.5374 ± 0.020 inch).

3. Install primary timing chain.

Let me know how everything works out for you. I have to be honest, I'm not sure why the starter engaged when you did it manually, but not with the switch. That seems odd.

Joe

Was this helpful?

Yes

No

Saturday, August 15th, 2020 AT 10:19 AM