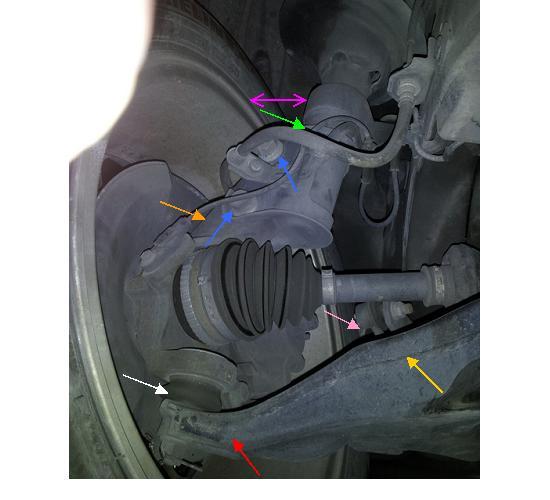

The green arrow is pointing to the area of the strut that gets bent. That bend can be too small to see and still cause the wheel to tip a lot. Look at the metal under the the bolts and nuts, (blue arrows), to see if there is any sign they have moved. You'll see shiny black paint with no road dirt, or silver metal where the pain was scrapped off if they moved. The lower hole is either oblong or can be ground oblong to allow movement. That is the method of adjusting camber on your car. Taking that perfectly round hole and grinding it oblong less than 1/16" will provide about two degrees of adjustment. That's way more than necessary to make any corrections during a routine alignment. I doubt that lower hole could have ever been ground enough to allow as much positive camber as you have so even if the bolts moved, that's not going to be the whole story.

After a severe hit like this, most mechanics will want to replace the lower ball joint to insure a proper repair. The white arrow is pointing to the dust boot covering the stud that can be bent. The stud must be removed from the spindle to be inspected, but you'll only know for sure it's bent if it has a "Z"-shaped bend. It can also easily be bent in such a way that is very hard to see. The impact will have pounded a lot of sideways stress on the nylon insert in the socket. That will cause some looseness that will grow faster and faster with each bump you hit in the road. Any sideways movement between that ball and socket will prevent an alignment from holding so no conscientious mechanic will even try to align a car with a sloppy ball joint.

That ball joint stud can't bend enough to cause as much positive camber as you have so we have to keep looking. The orange arrow is pointing to the upper part of the knuckle that has been known to bend but it is considerably stronger than the lower part of the strut that's bolted to it. If it bends bad enough, you might be able to see hairline cracks in the surface rust, or that rust is flaking off.

Up to now, everything I've mentioned assumes the top of the wheel is moved out, but remember, it was the bottom of the wheel that was forced IN during the impact. To bend the strut, the wheel had to act as a lever pivoting on the ball joint stud to bend something out on top. That much force could have pushed the control arm mounts in. To find that, measure the distance between the lip of the wheel to the strut body, (purple double arrow), and compare that to the other side. If that distance is greater on the right side, the strut is bent or shifted, or the knuckle is bent. If you find that measurement is the same on both sides, that area is okay and the bottom of the wheel has to have been pushed in. In that case, compare the lower control arm mounts on both sides of the car. Two bolts go through those mounts and rubber bushings that the control arm pivots on. The mounts are just to the right of the yellow arrow. There's a front one and a rear one on each side. Together with the lower ball joint, that arm is a big triangle.

The pink arrow is pointing to the outer anti-sway bar link. The bottom ball has popped out of the socket so the entire link must be replaced. This part doesn't have any affect on the alignment, it has nothing to do with the wheel being tipped, and doesn't have to be replaced before the alignment is done. It DOES show that the front end took a pretty good wallop to break that joint.

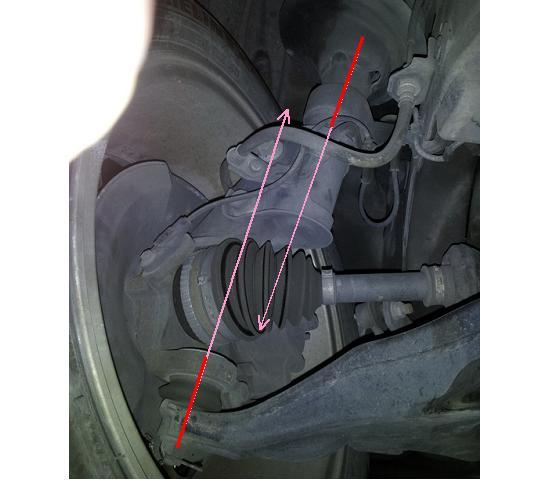

In the second photo, notice that the centerline of the ball joint and the centerline of the strut are not in line. Compare that to the other side of the car. That could be an optical illusion from the camera angle, it could be designed in to cause a camber change when cornering, or it could be a clue to finding bent parts.

These are the kinds of things they'll look for at the alignment shop. Comparing the two sides of the car is easier done when they're standing right there in front of it.

SPONSORED LINKS

Was this helpful?

Yes

No

Thursday, January 26th, 2012 AT 7:33 PM