Very happy to hear it's solved. When the lower control arm can move, two alignment angles, camber and caster change. Both have a real big affect on pulling to one side on rear-wheel-drive cars. Caster has very little affect on pull on front-wheel-drive cars, but camber will cause a pull, and a sloppy control arm bushing, (or loose bolt), will cause it to change when you're on or off the gas.

I should mention too that you most likely had the car jacked up when you tightened that bolt. If it's one of those I'm thinking of that goes through a control arm rubber bushing, that bolt should only be tightened when the car is at rest on the wheels. That means crawling underneath or driving it onto a drive-on hoist. The bolt will hold that bushing in the position it's in when it's tightened. If that's done when the suspension is drooping from the car being jacked up, that bushing will be held in a permanent twist when it is set back on the ground. Bouncing down bumpy roads will twist that bushing beyond its limits and lead to early failure.

Also, since the bolt was loose, the control arm would have been hammering it back and forth and would likely have stretched the hole in the frame. That would inadvertently put an adjustment into the car that needs to be set properly with an alignment. Because of the geometry of the steering system, anything that moves the position of the bottom of the wheel will also move the steering connection on the strut. That will cause the wheel to turn. Since that will make the car steer to one side, you have to correct that by turning the steering wheel. If you don't put the control arm back exactly where it was, (still assuming that mounting hole is hammered out), the steering wheel will be off-center.

You'll need an alignment anyhow due to the new tie rod ends. Be sure to mention the loose bolt so they adjust its position if necessary, and ask them to loosen and retighten it on the drive-on hoist if necessary. I had that problem with my car many years ago but there was not a single hint of a problem until right after I performed a maintenance alignment. When I finally found the cause, it was the mounting hole in the frame worn out making it twice as wide as it should have been. The fix was to remove the bolt so a washer could be installed on each end, the position of it was set on the alignment machine, then I tack-welded the washers in place to prevent the bolt from sliding in case I hit a big pothole.

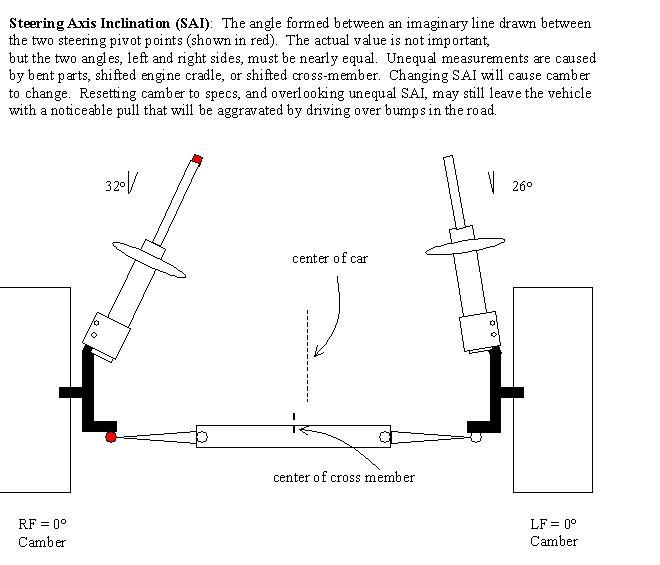

As for SAI, it's measured automatically by every alignment computer when it measures caster. Those numbers should be on the printout. It's considered a secondary alignment angle so it isn't looked at unless someone is trying to solve an elusive problem. In the absence of any handling complaint, it isn't corrected as part of a normal maintenance alignment.

Here's a part of a Notes Page I produced for my students that shows what SAI is and how it can be off even though camber is in specs.

Image (Click to make bigger)

Tuesday, September 6th, 2011 AT 8:50 AM