Hi,

His list of possible causes is very accurate. What I would suggest is checking first for a vacuum leak. Here is a link that shows how it's done:

https://www.2carpros.com/articles/how-to-use-an-engine-vacuum-gauge

If no leaks are found, check to make sure the fuel pressure is within the manufacturer's specs. Here is a link that shows in general how it's done:

https://www.2carpros.com/articles/how-to-check-fuel-system-pressure-and-regulator

Here are the directions for testing fuel pressure along with a diagnostic flow chart explaining what to check if there are variations in the system. The attached pics correlate with these directions.

____________________________________________________

1996 Dodge Neon L4-2.0L DOHC

Fuel Pressure Test

Vehicle Powertrain Management Fuel Delivery and Air Induction Fuel Pump Fuel Pressure Testing and Inspection Component Tests and General Diagnostics Fuel Pressure Test

FUEL PRESSURE TEST

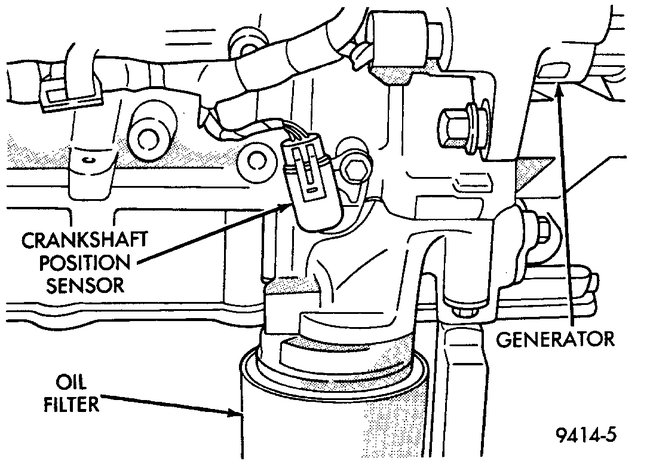

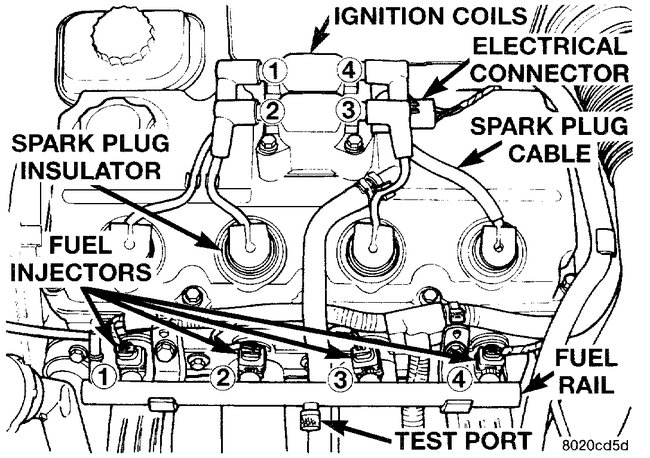

Fig. 7 Fuel Pressure Test Port - Typical

See pic 1

NOTE: The fuel system operates at approximately 331 kPa (48 psi). Check fuel system pressure at the test port on the fuel rail (Fig. 7).

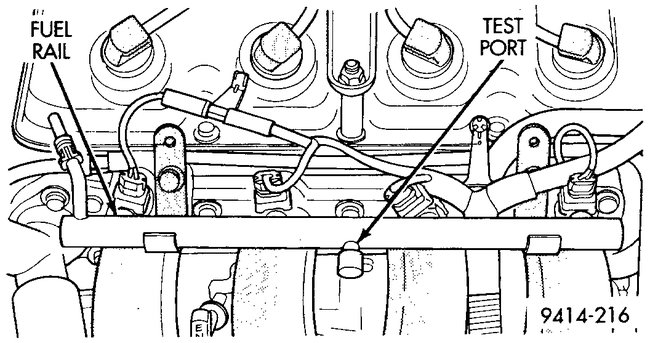

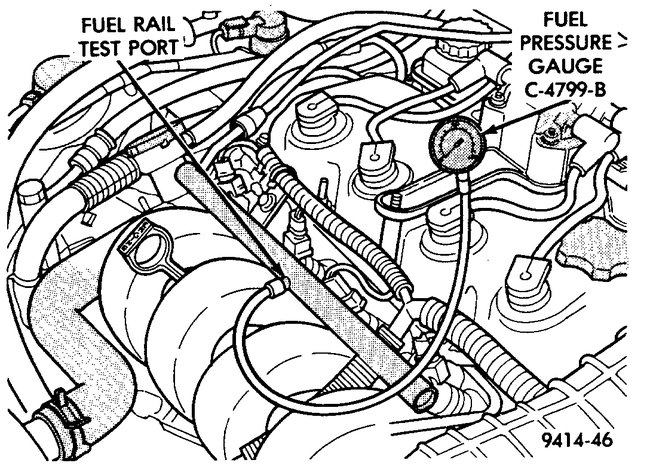

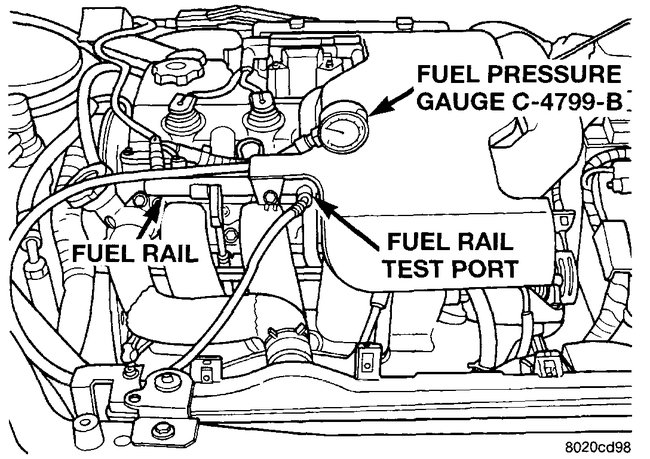

Fig. 8 Checking Fuel Pressure at Intake Manifold - Typical

See pic 2

1. Remove cap from fuel pressure test port on fuel rail.

2. Connect Fuel Pressure Gauge C-4799B to test port (Fig. 8).

CAUTION: When using the Auto Shutdown (ASD) Fuel System Test, the ASD relay and fuel pump relay remain energized for 7 minutes or until the test is stopped, or until the ignition switch is turned to the Off position.

3. Place the ignition key in the ON position. Using the DRB scan tool access ASD Fuel System Test. The ASD Fuel System Test will activate the fuel pump and pressurize the system.

- If the gauge reading equals 331 kPa (48 PSI) further testing is not required. If pressure is not correct, record the pressure.

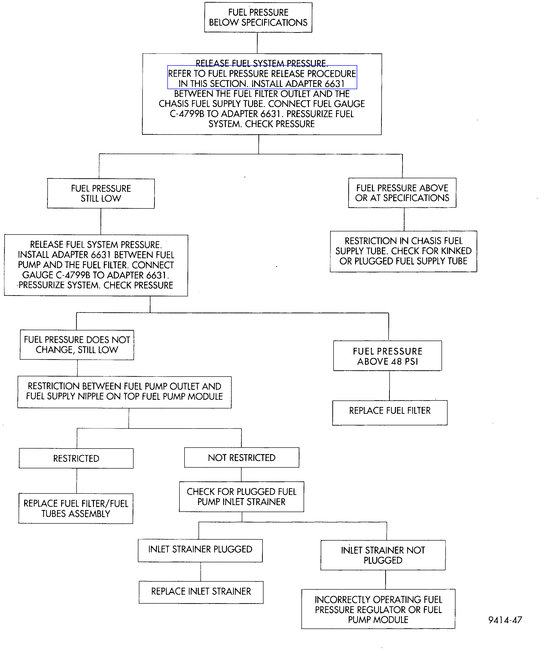

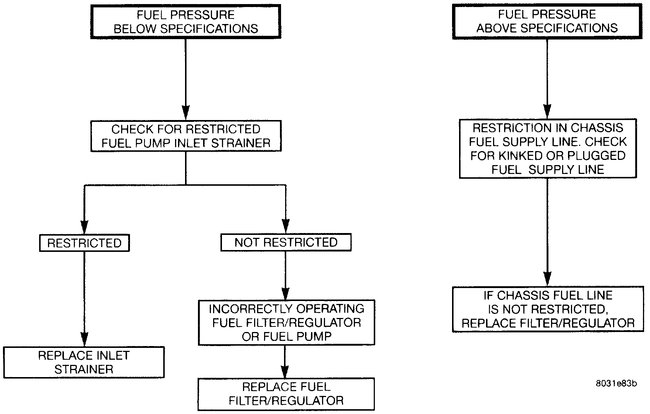

- If fuel pressure is below specifications, refer to the Fuel Pressure Diagnosis Chart (Fig. 9) below.

- If fuel pressure is above specifications (54 psi or higher) check for a kinked or restricted fuel supply line. If the supply line is not kinked or restricted, replace the Fuel Filter/Pressure Regulator.

Fig. 9 Fuel Pressure Diagnosis Chart

See pic 3

4. Replace Pressure test port cap when finished doing pressure test.

_____________________________________________________________

Also, if pressure is low, it could be the result of a partially plugged fuel filter. The filter on this vehicle is on the top of the fuel tank and is a combined filter / regulator unit. Here are the directions if you want to replace it. The remaining pics correlate with these directions.

_____________________________________________________________

1996 Dodge Neon L4-2.0L DOHC

Filter/Pressure Regulator

Vehicle Powertrain Management Fuel Delivery and Air Induction Fuel Filter Service and Repair Procedures Filter/Pressure Regulator

FILTER/PRESSURE REGULATOR

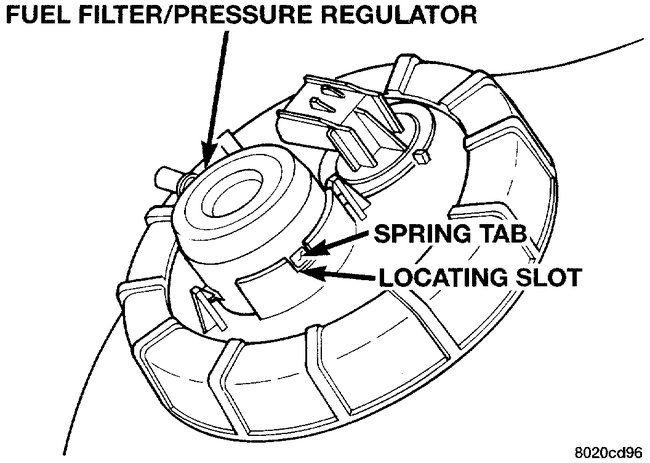

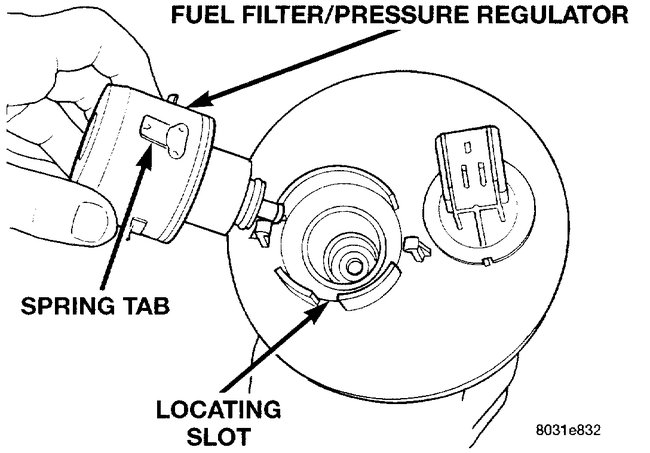

Fig. 18 Locking Spring Tab

Pic 5

WARNING: The fuel system is under a constant pressure, even with engine off before servicing the fuel filter/fuel pressure regulator, the fuel system pressure must be released.

NOTE: The fuel filter/fuel pressure regulator is located on the top of fuel pump module. Fuel pump module removal is not necessary.

REMOVAL

1. Raise vehicle on hoist.

2. Disconnect fuel supply line at the Filter/Regulator nipple.

3. Depress locking spring tab on side of Fuel/Regulator (Fig. 18) and rotate 9O° counter-clockwise and pull out.

NOTE: Make sure that the upper and lower 0-rings are on the Filter/Regulator assembly, and lightly lubricate the 0-rings with engine oil.

Fig. 19 Spring Tab In Locating Slot

Pic 6

INSTALLATION

1. Insert filter/regulator into the opening in the fuel pump module, align the two hold down tabs with the flange.

2. While applying downward pressure, rotate the Filter/Regulator clockwise until the the spring tab engages the locating slot (Fig. 19).

3. Connect the fuel line to the Filter/Regulator.

4. Lower vehicle from hoist.

_____________________________________________________________

Also, if you have an exhaust manifold leaking, it too can cause a lean mixture by allowing fresh air enter the exhaust system before reaching the oxygen sensor. Note: If you are checking for vacuum leaks using one of the products indicated in the above link, do not spray anything on the exhaust manifold to check.

_____________________________________________________________

Let us know if you have questions or need help.

Take care,

Joe

Images (Click to make bigger)

Friday, April 16th, 2021 AT 1:30 PM