An automotive engine water pump is bolted to the front of the engine and sealed to the block using gaskets and is designed to circulate coolant throughout the engine block, cylinder heads, radiator and heater. There are several designs in which the pump can be mounted to the engine, a popular method is to use the water pump to sandwich the timing cover to the block using the water pump mounting bolts. The pump's impeller is responsible for circulating the cooling and can be exposed when the water pump is removed from the engine. If the bearing of the pump fails it can cause the impeller to contact the timing cover housing causing the water pump to leak making grinding or squeaking noises.

Water Pump Cutaway

A water pump is made up of the metal pump housing, main shaft seal, bearings and a fluid impeller. A flanged hub is fitted to the main shaft where a pulley can be bolted on so a serpentine belt can drive the pump once the engine is started, it can also be driven by a timing belt or chain of the engine. The video below shows a water pump bolted to the engine block and how the timing cover is used as part of the pump's impeller housing. The problem with engine's that have a water pump that is driven by the timing chain is when the pump goes bad it will allow coolant to enter the engine oil which can cause the engine bearings to fail.

Watch the Video!

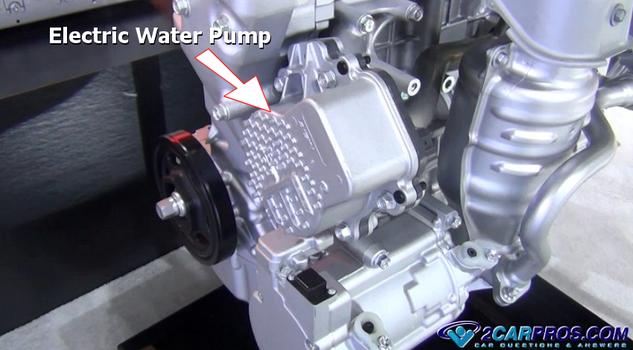

Hybrid Water Pump

As the engine's RPM changes the water pumps flow rate will increase or decrease

as well. This is not the case for water pumps designed for hybrid cars. Most hybrid

engine's water pumps are electric and are driven by a small electric motor mounted

inside of the pump housing. An example of this style of water pump is featured in

the image below.

Questions?

Our certified technicians are ready to answer car repair questions for free. We hope you saved money and learned from this guide and video, we are creating a full set of car repair guides. Please subscribe to our 2CarPros YouTube channel and check back often for new videos which are uploaded regularly.