Welcome to 2CarPros.

Although you hear the fuel pump, it may not be producing enough pressure to run the engine. What I suggest is to check for three things, spark to the plugs, fuel pressure, and for a signal to the injector. If one is missing or weak, that is where we will focus.

Here are links showing how in general to check the aforementioned components. Take a look through them and let me know the results.

https://www.2carpros.com/articles/how-to-check-fuel-system-pressure-and-regulator

https://www.2carpros.com/articles/how-to-test-an-ignition-system

https://www.2carpros.com/articles/how-to-test-a-fuel-injector

Here are the directions specific for testing fuel pressure and the regulator. The attached pics correlate with the directions.

_____________________________________

WITH GENERIC SCAN TOOL

Fuel Pressure Regulator and Residual Pressure, Checking

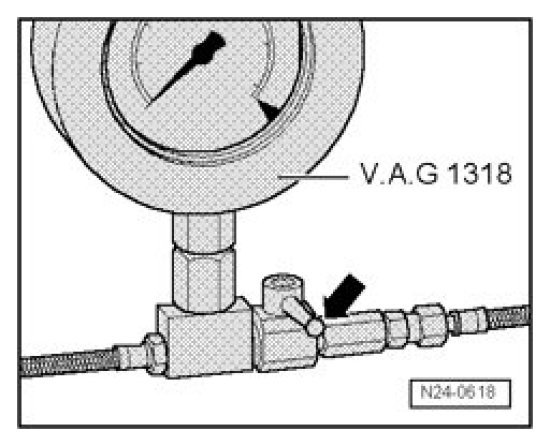

picture 1

Function

The fuel pressure regulator controls the fuel pressure as a function of the Manifold Absolute Pressure (MAP).

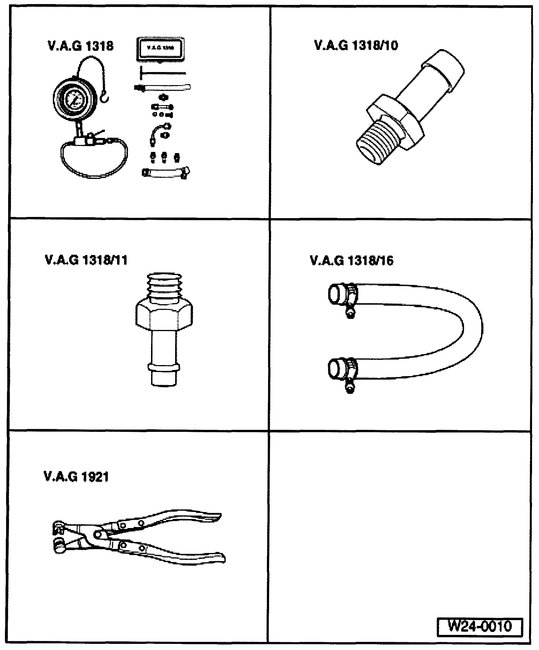

Special tools and equipment

- V.A.G1318 pressure gauge

- V.A.G1318/10 adapter

- V.A.G1318/11 adapter

- V.A.G1318/16 hose adapter

- VAS5024 Assembly tool for spring-type clamps.

Test requirements

- Parking brake must be engaged or else daylight driving lights will be switched on.

- For vehicles with automatic transmission, selector lever must be in -P-.

- Delivery quantity and Fuel Pump (FP) check-valve OK

Note: Note function description of crash fuel shut-off, vehicles 09.99 >

Test sequence

- Observe safety precautions

- Observe rules for cleanliness

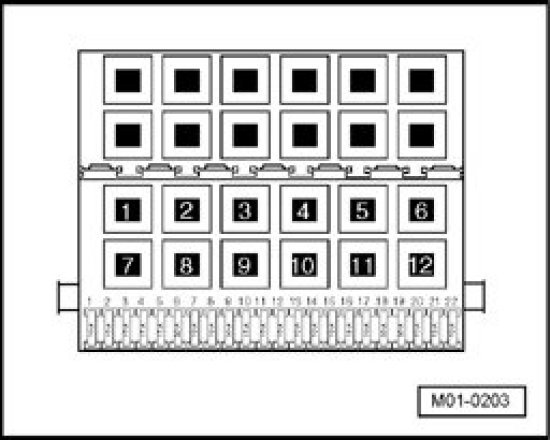

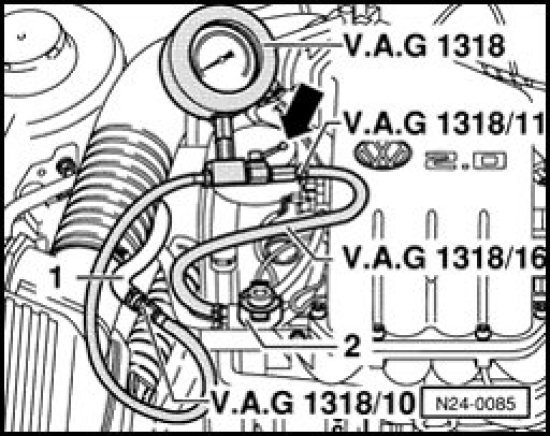

picture 2

- Remove fuse no. 18 from fuse holder.

WARNING!

The fuel or fuel lines in fuel system can become very hot (danger of scalding)!

In addition, the fuel system is under pressure! Before opening the system, place rags around the connection area and release pressure by carefully loosening the connection!

Wear protective goggles and protective gloves when working on the fuel system!

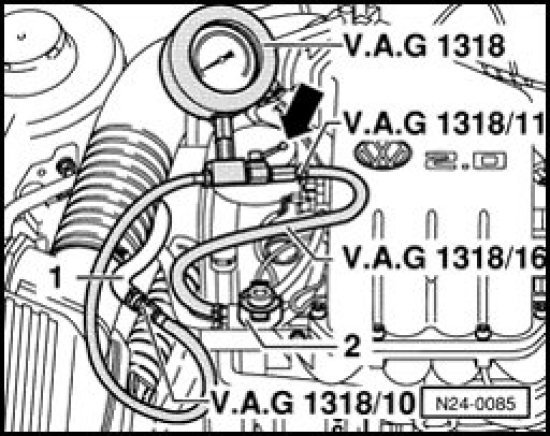

picture 3

- Disconnect fuel supply line -1- from connection on fuel rail -2- and connect to adapter V.A.G 1318/10 at pressure gauge V.A.G 1318

- Use a rag to catch escaping fuel.

- Connect pressure gauge (V.A.G 1318) with adapters (V.A.G 1318/11) and (V.A.G 1318/16) to fuel rail -2-.

- Open pressure gauge shut-off valve. The lever points in the direction of flow (arrow).

- Re-insert fuse 18 (fuel pump) into fuse holder.

- Start engine and let run at idle.

- Measure fuel pressure.

Specified value: approx. 2.5 bar positive pressure

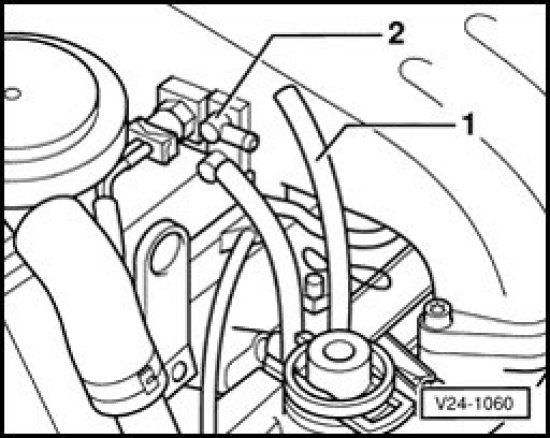

picture 4

- Disconnect vacuum hose -1- from connecting piece -2-. Fuel pressure should rise to approx. 3.0 bar positive pressure rise.

- Switch ignition off.

Note:If fuel should escape at the vacuum connection of the pressure regulator, replace fuel pressure regulator.

- Check for proper seal and residual pressure. Observe pressure drop on pressure gauge for this. After 10 minutes at least 2.0 bar positive pressure should still be present.

If residual pressure falls below 2 bar positive pressure:

- Start engine and let run at idle.

picture 5

- Wait until pressure has dropped, and then switch off ignition. Simultaneously close pressure gauge shut-off valve (lever perpendicular to direction of flow -arrow-).

- Observe pressure drop on pressure gauge.

If pressure does drop again:

- Test check-valve of Fuel Pump (FP)

If pressure does not drop:

picture 6

- Open stop valve of pressure gauge (lever in direction of flow -arrow-).

- Start engine and run at idle.

- Wait until pressure has dropped, and then switch off ignition. Simultaneously pinch return hose tightly together.

If pressure does not drop:

- Replace fuel pressure regulator.

- Erase DTC memory of Engine Control Module (ECM), Diagnostic mode 4: Reset/erase diagnostic data.

- Generate readiness code.

If pressure does drop again:

- Check whether line connections, O-rings in fuel distributor, and fuel injectors are properly sealed.

- Check pressure gauge for proper seal.

Note: Before removing pressure gauge, put cleaning rags back around line connection which is to be disconnected.

- Erase DTC memory of Engine Control Module (ECM), Diagnostic mode 4: Reset/erase diagnostic data.

- Generate readiness code.

______________________________________

Let me know the results or if you have other questions.

Take care,

Joe

Images (Click to make bigger)

SPONSORED LINKS

Friday, May 10th, 2019 AT 10:04 PM