Hi guys. If I followed that correctly, It sounds like you are getting a voltage reading at the sensor's connector, but not at the other end of the two-foot harness that connects to the sensor. What I am interested in first is the resistance reading at the sensor's connector. A typical value that I am familiar with is around 450 - 750 ohms, so I am going to use that for now. JIS001 hit the checks for either wire being shorted to ground and twelve volts, but once you know the resistance value of the sensor, (lets say 500 ohms), plug in the two-foot harness, then recheck the resistance from that point. It should still be 500 ohms. If you find close to 0 ohms, the two wires are shorted together in that two-foot harness. It was also suggested to measure the continuity from the computer. That would also show right away if the two wires were shorted together anywhere, and if continuity is okay.

The little tidbit of value I wanted to add is this type of magnetic sensor develops a positive voltage when a notch in the tone ring approaches the magnet in the sensor, and it generates a negative voltage when the notch moves away from the magnet. As such, it develops an AC sine wave, so measure the signal on the meter's AC volts scale.

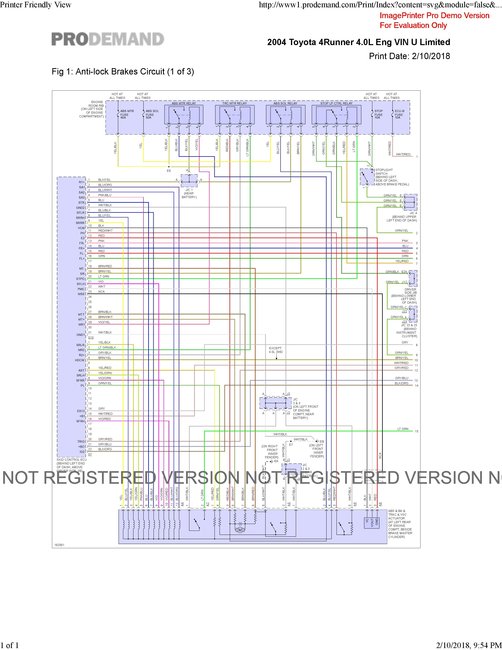

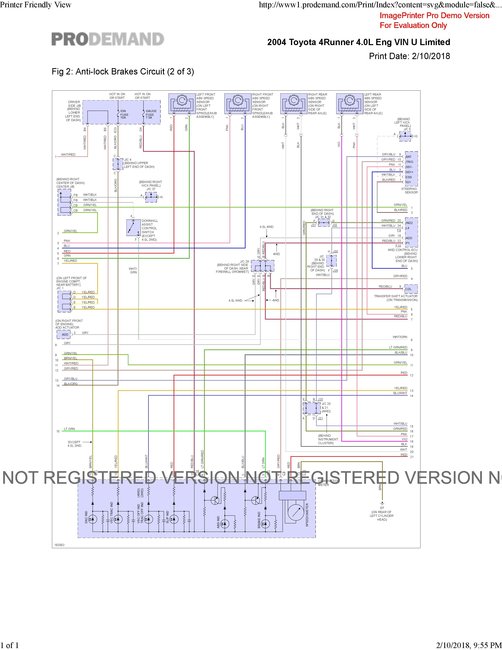

The second comment of value has to do with the comment about finding twelve volts feeding one of the wires going to the sensor. When that is done, it can be for two reasons. The first is if that wire becomes grounded, it shorts out that twelve volts, and that is how the computer knows to set a diagnostic fault code related to that wire being grounded. Without that more specific code, all the computer could do is set a code related to the missing signal. That leaves it up to you to narrow down the cause.

The other reason is speed is a factor in the strength of the signal voltage that is developed. When these sensors develop real low voltages under normal conditions, then they get weaker at low speeds, those signals can drop too low for the computer to detect. To get technical for a moment, it takes 0.6 volts to turn on a standard transistor, then that transistor starts to do its thing, meaning amplify or pass a signal. Once it reaches that 0.6 volt turn-on voltage, it can amplify real tiny voltages of just a few thousandths of a volt. Rather than waiting for vehicle speed to get high enough for the sensor to reach 0.6 volts, they will put a "bias" voltage on the line, in this case, 10.80 volts. That is plenty to turn any transistors on in the computer, then it is a simple matter of watching the tiny voltage changes the sensor generates.

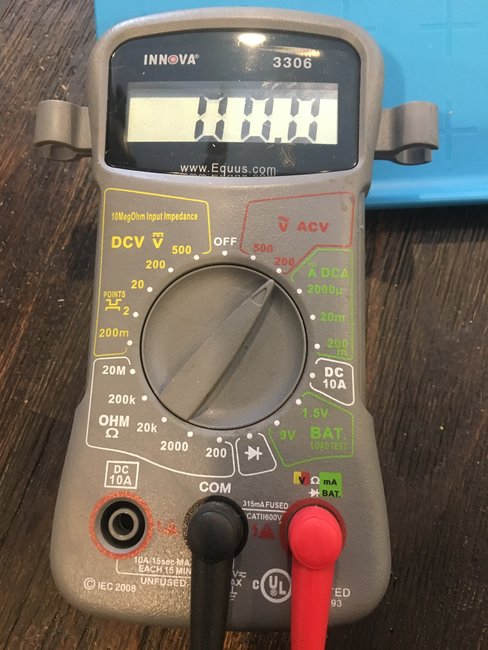

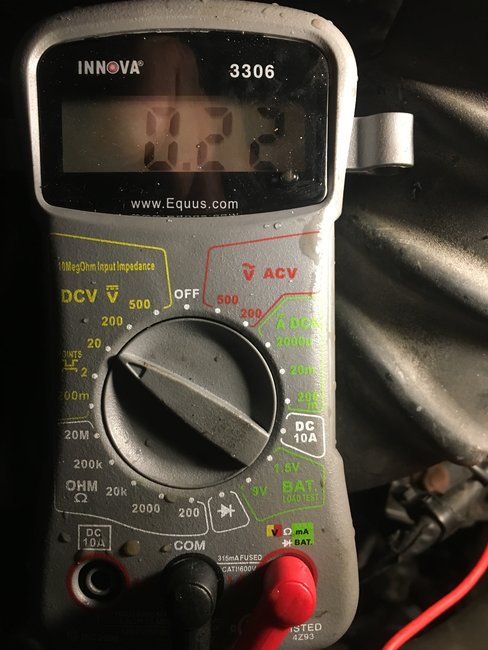

To add to the misery, you might measure that 10.80 volts when the sensor is unplugged, but when connected, the sensor's resistance might draw that voltage down to a more typical six volts. Where this becomes an issue is when taking voltage readings with the sensor plugged in and connected to the computer. On DC volts, you would see the bias voltage of 10.80, (or six volts), but that is supplied by the computer and is not going to change when the wheel is spun. The problem is digital meters take a reading, analyze it, then display it while it takes the next reading. One of those readings might be, lets use my six volts, plus the additional 0.1 volt generated by the sensor. The next reading might get taken when the negative half cycle is generated, so it would see 5.9 volts. The display would bounce around and be somewhat unreadable or at least unsteady. You would be scratching your head trying to understand what the reading means.

When you use the meter on the AC Volts ranges, it automatically blocks the DC component, so in my story, you'd only see the 0.2 volts when spinning the wheel.

For my next great and wondrous comment, on the AC volts ranges, digital meters are only accurate when measuring a 60 Hz sine wave which is house voltage. Some of the more expensive ones are still accurate up to 400 Hz for military use. When the tone ring has only 48 notches or teeth, the wheel has to rotate just over one revolution per second for the meter to be accurate. I am guessing that is about fifteen mph. At other speeds the meter loses its accuracy.

The related issue is wheel speed sensors often do not generate nice clean sine waves. They can generate a positive pulse, then after a short gap, they generate the negative pulse. That starts to look like a square wave pulse, just like when breaker points turn on and off. With a sine wave, current flows one way and increases gradually and smoothly from "0" to maximum positive, then back to "0". From there current goes the other way smoothly from "0" to maximum. Think of the smooth swing back and forth of a grandfather's clock pendulum. With a true square wave, the pendulum is first fully to the left, then instantly fully to the right. Think of how fast the pendulum has to move to get instantly to the other side. That extremely tiny amount of time is the counterpart to the real slow time it took for the signal voltage to rise from "0" to maximum for the sine wave. That is called the "rise time". With the sine wave it is smooth and long. With the square wave, it is extremely fast, and the meter sees that as an extremely high frequency. That could be in the range of many kilocycles, or khz, and that is way too high for the meter to respond to.

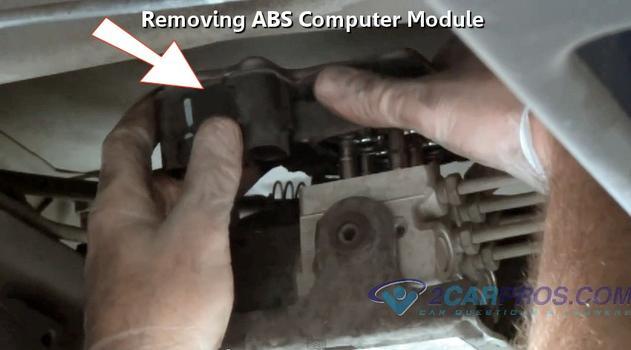

All of this sad story is to explain why a digital voltmeter is not good for getting reliable or accurate readings with wheel speed sensors. They might tell you whether you have something vs. Nothing, but there are too many variables to trust any readings as good or bad. There are two ways to know what is being generated for speed signals. One is to use an oscilloscope used for TV and VCR repair, but not too many mechanics have those. Some engine diagnostic scopes can be rigged up to display those signals, but the time involved is too high. Most problems are diagnosed and solved long before anyone is finished fashioning the test setup. The better way is to let the ABS computer decide whether the signals are okay. It is designed to accept the wide range of frequencies, and the actual voltage is not important. A scanner will show the miles per hour for each wheel, and I suspect there is a place to view the signal voltages. The only value in knowing the voltages would be to compare the readings to each other to see if one is weak. If a signal is weak, that is the time to suspect rust buildup that pushed the sensor away from the tone ring.

Hope this helps make sense of the confusing readings. Will wait to see what the solution is.

Monday, February 12th, 2018 AT 1:52 AM