You should be correct about vacumn leakages and it is one of my most dreaded situations, even more so without the presence of the physical vehicle.

One of the way to test for vacumn leakages is with the aid of carb cleaners. With engine running, spraying carb cleaner onto suspected leaking areas would result in the engine speed changing.

Let us start with possible areas that can be checked first before getting on with the carb cleaner.

Possible areas :

1. PCV valve.

2. Intake manifold gasket.

3. Vacumn hoses.

4. Vacumn valves/solenoids.

5. Carburettor gasket.

6. EACV

7. Air suction system.

If test and visual of the above components are non conclusive, then is time to get the carb cleaner.

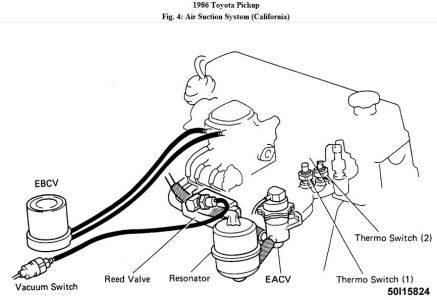

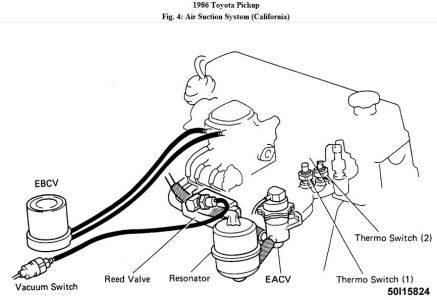

Below is a description and testing procedures of the air suction system.

1. Check condition of all hoses and tubes. Ensure coolant temperature is below 43 °F (6 °C). Start engine and ensure a bubbling noise is not heard from Electronic Air Control Valve (EACV).

2. Warm engine until coolant temperature is between 64-109 °F (18-43 °C). Maintain engine speed at 1390 RPM and check that a bubbling noise is heard from EACV.

3. Continue to run engine until coolant temperature is above 131 °F (55 °C). Maintain engine speed at 1390 RPM and check that a bubbling noise is intermittently heard from EACV.

4. Allow engine to return to idle and check that a bubbling noise is heard from EACV. With coolant temperature above 64 °F (18 °C) and engine under heavy load, disconnect vacuum hose from vacuum switch and plug end of hose. Ensure a bubbling noise is not heard from EACV.

Tuesday, February 16th, 2010 AT 12:41 AM