Good evening.

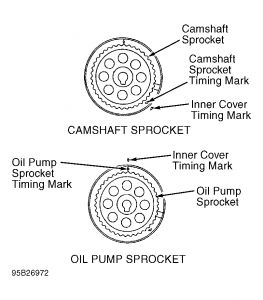

I attached the procedure for you below and also some pictures. Check out the diagrams (Below). Please let us know what happens.

Roy

REMOVAL

1. Remove spark plugs.

2. Align crankshaft so number one piston is at TDC (top dead center) as indicated by timing marks.

3. Remove outer timing belt cover.

4. Loosen timing belt spring pivot bolt. Do not remove.

CAUTION: If you attempt to remove timing belt or adjust tension without loosening both timing belt tensioner adjusting bolt and spring pivot bolt, you will break Camshaft Belt Tension Adjusting Tool T74P-6254-A when you attempt to relieve tension on belt.

5. Hold tensioner with Camshaft Belt Tension Adjusting Tool T74P-6254-A.

6. While holding tensioner, loosen adjusting bolt and gradually release spring tension.

7. Using adjusting tool, rotate tensioner, against spring pressure, as far clockwise as possible. While holding, tighten adjusting bolt to hold tensioner away from belt.

8. Remove timing belt.

INSTALLATION

NOTE: Care must be taken during timing belt installation to prevent damage to the inner timing cover.

1. If not done:

a. Loosen tensioner adjusting bolt.

B. Using Camshaft Belt Tension Adjusting Tool T74P-6254-A, pry tensioner clockwise against spring tension as far as possible.

C. Tighten adjusting bolt to hold tensioner in released position.

2. Align crankshaft so number one piston is at TDC (top dead center) with crankshaft key pointing straight up and circle on crankshaft sprocket aligned with notch in engine front cover.

3. Align triangle on camshaft sprocket with triangle on inner timing belt cover.

4. Align diamond on oil pump sprocket with diamond on inner timing belt cover.

5. Install timing belt over crankshaft sprocket. Then, proceeding counterclockwise, over oil pump sprocket and camshaft sprocket.

6. Loosen tensioner adjusting bolt allowing tensioner pulley to press against timing belt.

7. Rotate crankshaft two revolutions clockwise.

NOTE: When performing the following step, do not rotate crankshaft counterclockwise as timing belt may jump a cog, putting camshaft or camshaft position sensor on oil pump out of time.

8. Bring crankshaft slowly, without stopping, to number one cylinder firing position (keyway directly up).

9. Recheck timing mark alignment. Repeat steps if timing marks are not properly aligned.

10. Rotate tensioner assembly against belt with torque wrench up to 41-45 Nm (30-33 ft. Lbs.) And tighten adjusting bolt.

11. Tighten adjusting bolt to 35-45 Nm (26-33 ft. Lbs.).

12. Tighten spring pivot bolt to 40-55 Nm (30-40 ft. Lbs.).

13. Install outer timing belt cover.

Check out the diagrams (Below). Please let us know what happens.

Images (Click to make bigger)

SPONSORED LINKS

Thursday, November 12th, 2020 AT 4:57 PM