This is an extremely common problem on all brands. Most often caused by a failing crankshaft position sensor or camshaft position sensor. They commonly fail by becoming heat-sensitive, then they work again after cooling down for an hour. Most of the time they still keep working as long as you're driving. Natural air flow keeps those sensors cool. They like to fail when a hot engine is stopped for a short time, such as when stopping for gas, and engine heat migrates up to them.

One of the frustrating things is very often there will not be a diagnostic fault code to direct you to the circuit that needs further diagnosis. The Engine Computer needs some time to detect the missing signal, but the engine typically stops rotating too soon. Codes for those sensors often don't set just from cranking the engine.

The easiest way to figure out which circuit to look at is with a scanner to view live data. Under the "Inputs / Outputs" menu or "Engine Data" menu, both sensors are listed. I have a Chrysler DRB3 scanner for all of my vehicles. They list each sensor with a "No" or "Present" to denote whether the signals are showing up. Both will be listed as "No" with the ignition switch on, then both should switch to "Present" as soon as you start cranking the engine. When the stalling has just occurred, you're looking for the sensor that does not switch to "Present" when you crank the engine. There are quite a few nice aftermarket scanners today that display the same data. If you don't have access to one, you'll need to have a mechanic perform the test, but it has to be done while the problem is occurring.

It's important to understand, regardless if you're working from a diagnostic fault code or from the missing signal on a scanner, neither one ever says to replace a part or that one is defective. When a sensor or other part is referenced in a fault code, it is only the cause of that code about half of the time. First we have to rule out wiring and connector terminal problems, and mechanical problems associated with that part before spending our customer's money on that part.

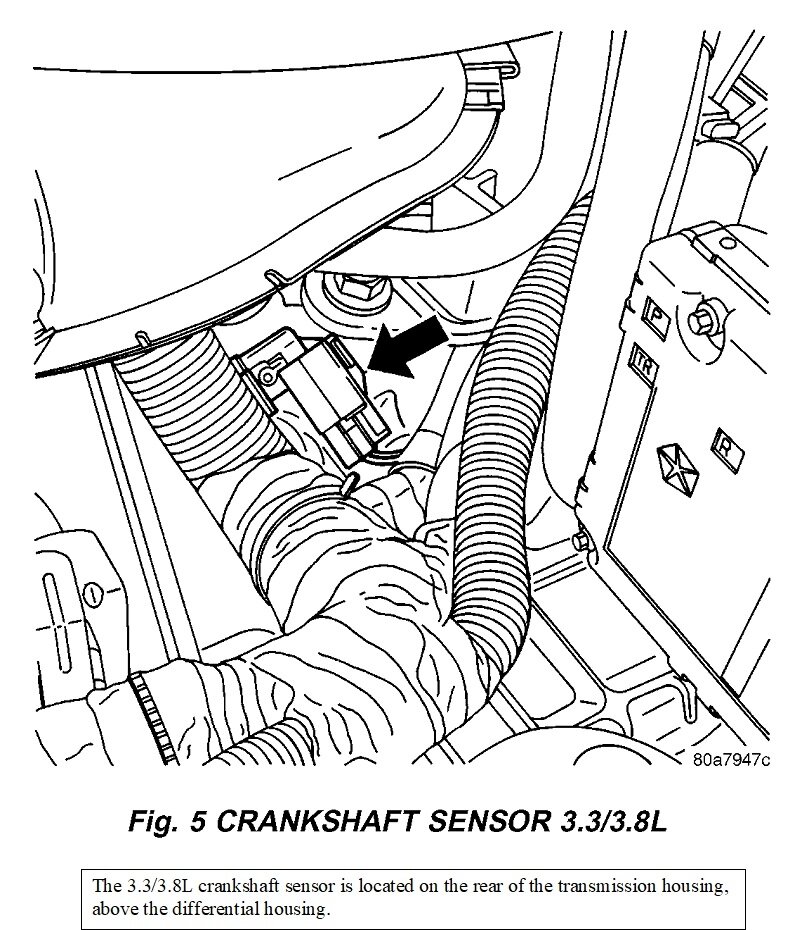

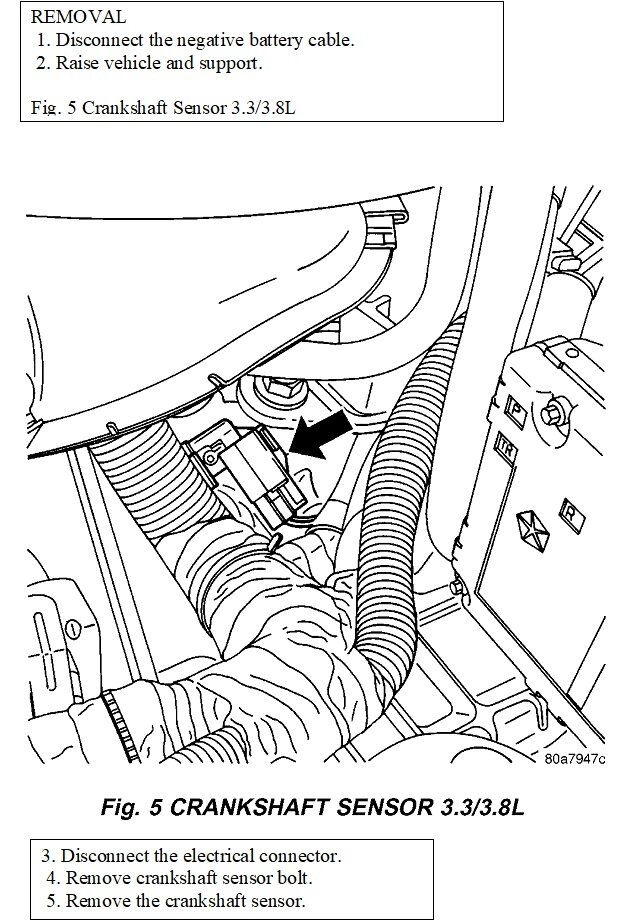

In this case, since this has been such a common problem, you might consider just replacing the crankshaft position sensor since it costs less than a trip to the repair shop. On older engines there was a very simple but important procedure to set the depth of the sensor. Yours is fixed with its mounting ear, so you just push the sensor in and bolt it snug. You can reach it from on top. It's near the driver's side of the engine, above the transmission.

The instructions say to raise the vehicle, which implies replacing the sensor from underneath, but I don't recall having to do that. If you do, please be sure to use jack stands:

https://www.2carpros.com/articles/jack-up-and-lift-your-car-safely

Let me know what you find, and if you need the instructions for replacing the camshaft position sensor.

Images (Click to make bigger)

Friday, March 17th, 2023 AT 2:31 PM