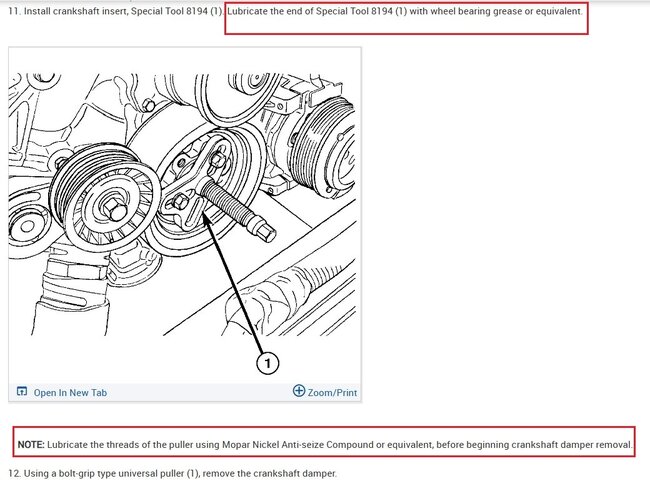

Don't use heat on the crankshaft, they recommend some grease on the end that actually contacts the crankshaft, and some anti-seize on the threads of the puller bolts. But I don't think you're going to find the timing being off, with just a single chain it's highly unlikely. With the components you have off already have you tried putting the crank bolt back in a turning the engine over by hand?

You have the BlueDriver scan tool with the App, which has live engine data, Mode 6 data, code reading and Freezeframe data for any codes set, there should definitely be enough live data to see what's going on. You should be looking for an RPM signal, Fuel injector pulse width, PCM voltage, etc. There has to be some data PID with inaccurate data listed, especially since the PCM at this point won't have any "learned" values that it could potentially substitute for missing or inaccurate values, which can happen when signed into the manufacturer side of scan tools instead of the Global OBD2 side, if the scan tool has that, I would use it instead of going into the Dodge side. I have one of these Bluetooth scan tools I keep in my truck in case I need to stop and help someone, and they have a lot of information in them.

Instead of potentially damaging the crank pulley, I would take a different approach, your compression readings are plenty high, and with the amount you have been cranking it over, if the fuel injectors were firing, I would expect much lower compression because of cylinder wash with all the fuel that would be spraying into the cylinders.

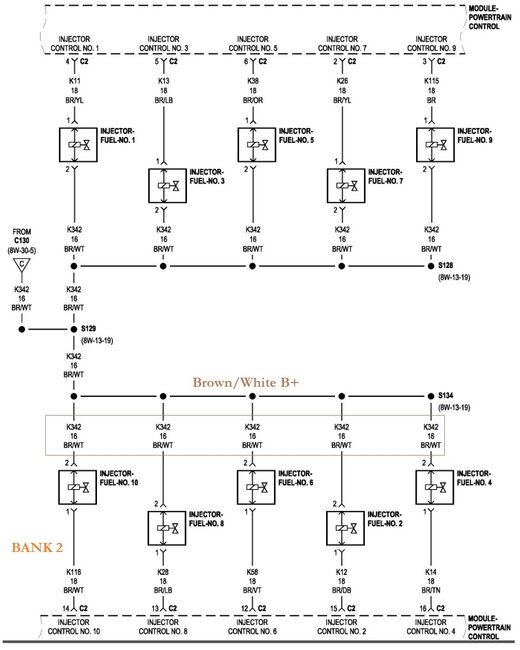

I think you might find there is no fuel injector pulse, or power missing to the injectors,

You mentioned you had fuel pressure, but that doesn't mean the injectors are firing, instead of pulling the timing cover off, put things back together to a point where you can check for an injector pulse. Pull a few spark plugs and I'll bet they will look perfect, might not even have any fuel on them, I just don't want to see you pull the timing cover just to see that it's in time.

Get it as far as being able to crank over with the battery hooked up, you don't even need the main belt to be on, isolate the alternator B+ cable so it doesn't short out on anything, and you can check the injector pulse with a test light, but you need the battery hooked up. If you can turn the engine over by hand and the power steering pump was your slow crank issue, or battery voltage dropping,

I'd put things back together, save yourself anymore headache with all that, you don't need the radiator, alternator, ac compressor or drive belt to check for the injector operations, we can go over that with these other parts still off, you can do a voltage drop test to the engine block and frame to make sure there's proper grounding, and then you can just put those other parts back on later once we see if there's injector control. Charge up the battery.

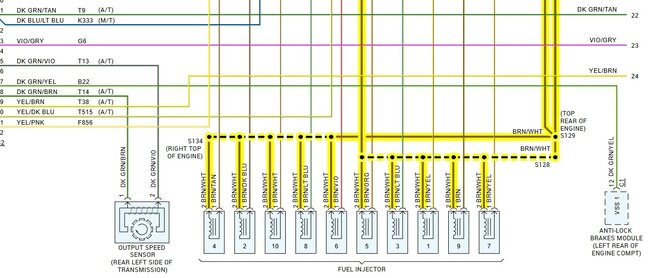

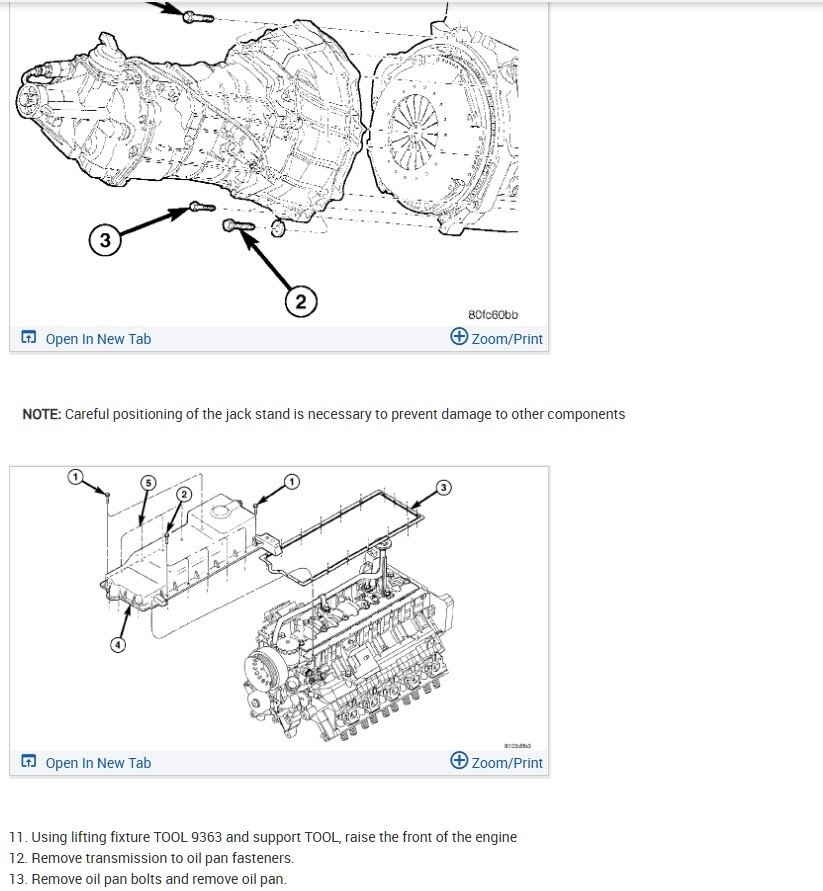

2nd diagram shows the fuel injector power wires the others are the ground side control wires, super easy to check for an injector pulse from the PCM.

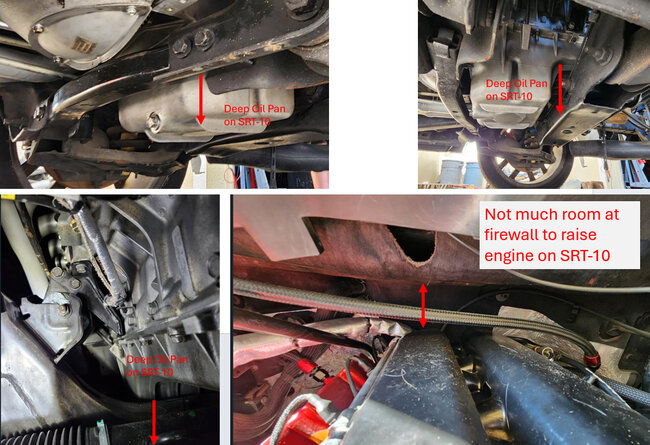

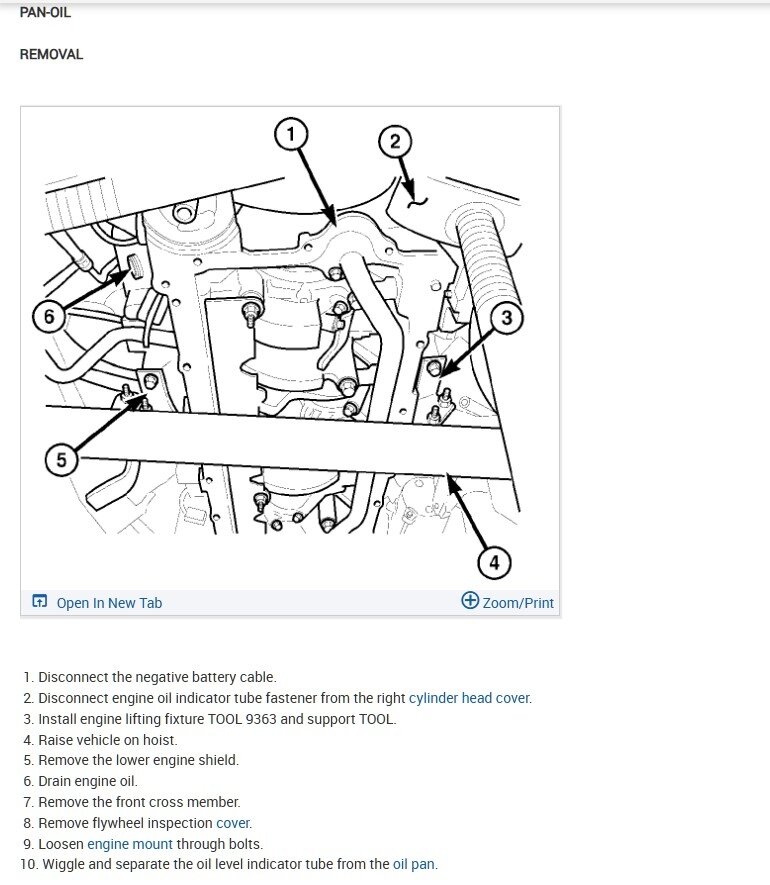

Images (Click to make bigger)

Tuesday, July 2nd, 2024 AT 5:32 PM