Yep that's it, here is the text on how to replace it it what it does,

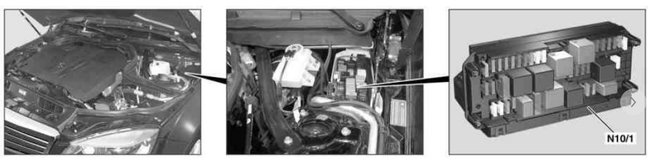

N10/1 Front SAM control unit with fuse and relay module

Location

The front SAM control unit with fuse and relay module is located at the left in the engine compartment.

Task

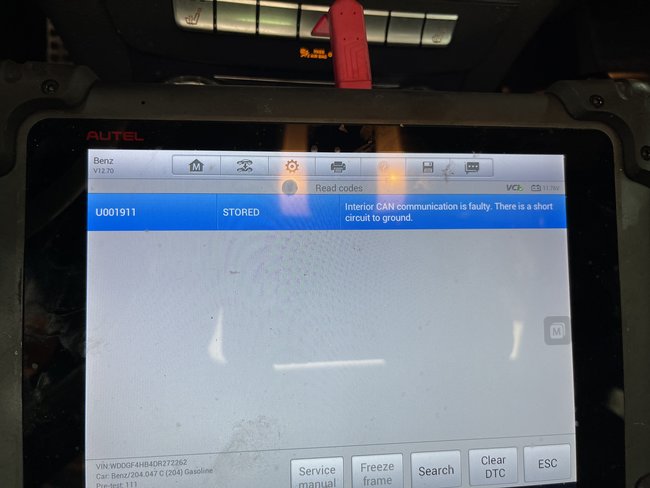

Two microprocessors are installed in the front SAM control unit, one for control of basic functions such as, e.G. The exterior lights (ABL), and the second for control of the central gateway functions. Both processors communicate internally with each other over the interior CAN (CAN B) and they can undergo separate diagnosis. The front SAM control unit also has a 3D acceleration sensor integrated into it which is used to detect any crash events.

For model 204.9 a speedy journey over uneven roads can cause significant vibrations which in turn may induce the 3D- acceleration sensor to be actuated. These are entered into an event memory. When mounting, make sure that the front SAM control unit is securely seated.

The processor is responsible for the following tasks for controlling the central gateway functions:

- Central gateway (CAN interface)

- Data container

- System diagnosis

- Global variant coding

- Monitoring CAN bus idle

The processor is responsible for the following tasks for controlling the basic functions:

- Interior CAN and LIN interface

- Reading in of sensors, pickups and signals

- Evaluation of input factors

- Controlling functions

- Actuation of components

The fuse and relay module of the front SAM control unit supplies various systems and control units with power through limit switches to match the function sequence.

The following tasks are the responsibility of the fuse and relay module:

- Voltage supply to components

- Power supply and relay switching

- Switching consumers using relays

Detailed information is available in the "Fuse and relay box, asbuilt configuration" function description.

Central gateway (CAN interface)

The processor for controlling the central gateway functions also acts as an interface between the following data bus systems:

- Interior CAN

- Diagnostic CAN (CAN D)

- Chassis CAN (CAN E)

- Front end CAN (CAN G)

Data container

The data container represents a nonvolatile, mobile data memory and is managed by the processor for controlling the central gateway functions.

Benefits:

During production, vehicle-specific, test location-specific and control unit-specific data are stored in the data container (e.G. Production number, test status, partial tests not completed). These data can be used in the subsequent tests for test sequence control. The total size of the data memory is 128 bytes.

System diagnosis

The system diagnosis is integrated as a software module in the processor for controlling central gateway functions.

For off-board diagnosis, the following on-board functions are realized by the processor responsible for controlling the central gateway functions:

- CAN line diagnosis

- CAN SPECIFIED/ACTUAL configuration

- Data logger for telediagnosis

Global variant coding

The processor responsible for controlling the central gateway functions forwards global information such as model series and national version over the various CAN buses to the networked control units. The control units perform part of their configuration process to match this information.

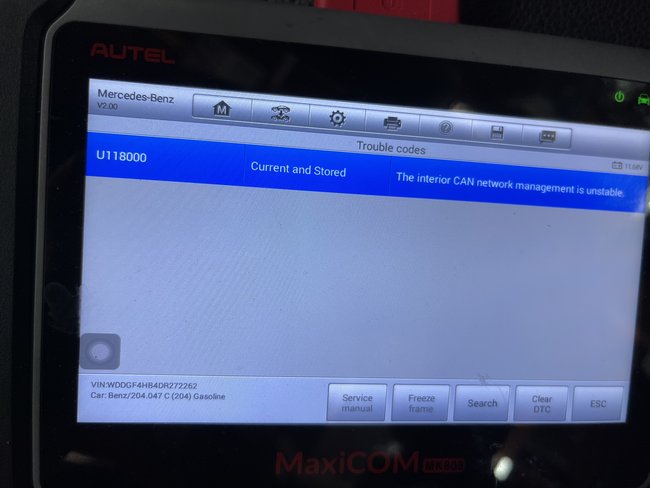

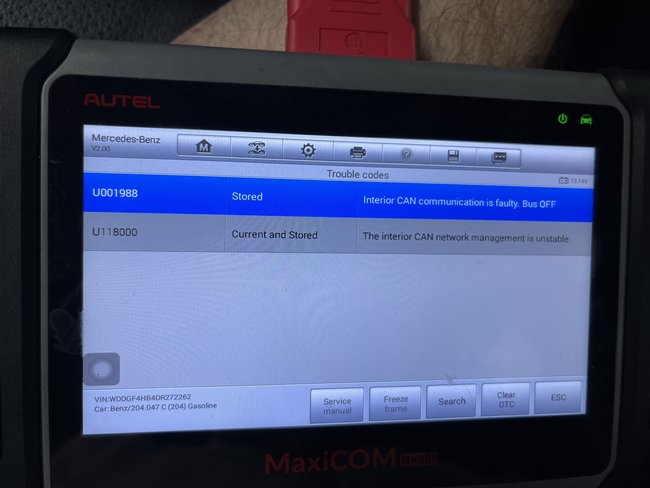

Monitoring CAN bus idle

The monitoring of the CAN bus idle enables control units to be determined, which keep the CAN bus active at what otherwise is expected to be a CAN bus idle period.

This information is filed in a nonvolatile memory. This in turn serves to ensure that even when the on-board electrical system battery (G1) has been discharged and following a reset of the networked control units, it is still possible to determine whether the discharging of the on-board electrical system battery was caused by the network or by an individual CAN user.

Interior CAN and LIN interface

The processor for controlling the basic functions also acts as an interface between the following data bus systems:

- Instrument panel LIN (LIN 1)

- Wiper/inside rearview mirror LIN (LIN 2)

- Interior CAN

Reading in of sensors, pickups and signals

The input factors are read in via the following connections:

- Direct line

- Instrument panel LIN

- Wiper/inside rearview mirror LIN

- CAN

Direct line

The processor for actuating the base functions reads in the signals of the following components over direct lines:

- Refrigerant pressure sensor (B12)

- Outside temperature sensor (B14)

- Interior temperature sensor with integrated fan (N70/3b1) (without code (414) Electric glass tilting/sliding roof)

- Exterior lights switch (S1) (as of 1.6.10)

- Right front brake wear sensor (S10/2)

- Right rear brake wear sensor (S10/4)

- Brake fluid level switch (S11)

- Parking brake indicator switch (S12)

- Backup lamp switch (S16/2) (for transmission 711, 716)

- Coolant level switch (S41)

- Windshield washer system fluid level switch (S42)

- With code (B03) ECO Start-stop function

- Additional battery (G1/7) (Charge level)

- Right engine hood contact switch (S62/42) (without code (U60) Pedestrian protection)

Instrument panel LIN

The processor for controlling the basic functions reads in the signals from the following components over an instrument panel LIN:

- Upper control panel control unit (N72/1)

- Exterior lights switch (up to 31.5.10)

- Instrument panel switch group (S6/1)

Wiper/inside rearview mirror LIN

The processor responsible for controlling the basic functions reads in the signals from the following components over a wiper/inside rearview mirror LIN:

- Inside rearview mirror (A67) (with code (249) Automatically dimming inside rearview mirror and outside mirror (driver))

- Garage door opener (A67n2) (with code (232) Garage door opener with frequency 284-390 MHz)

- Light sensor (B38/1) (model 204.0/2 up to 28.2.11, model 204.9 without code (345) Rain sensor)

- Rain/light sensor (B38/2) (model 204.0/2 up to 28.2.11, model 204.9 with code (345) Rain sensor, model 204.0/2 as of 1.3.11, model 204.3)

- Interior temperature sensor with integrated fan (N70b1) (with code (414) Electric glass tilting/sliding roof)

The communication with the processor responsible for controlling the central gateway functions can also send the data read in by the processor responsible for controlling the basic functions to control units that are not connected to the interior CAN.

CAN

The processor responsible for controlling the basic functions reads in function-relevant data over the interior CAN.

Information from control units that are not connected to the interior CAN are sent by the processor responsible for controlling the central gateway functions over the interior CAN. This can be information from control units, which are connected to one of the following CANs:

- Chassis CAN

- Front end CAN

- Diagnostic CAN

The functions that use these signals are described in the individual function descriptions (see block diagram or function schematic).

Evaluation of input factors

The input factors are evaluated by the processor responsible for controlling the basic functions whereupon the corresponding components are then actuated.

Controlling functions

The processor responsible for controlling the basic functions manages the following functions:

- ABL

- Interior illumination (IBL)

- Wiper system (WSA)

- Windshield washer heater (with code (875) Heated windscreen washing system)

- Headlamp cleaning system (with code (600) Headlamp cleaning system)

- Central locking (CL) for rear doors, crash opening (up to 30.11.09)

- Rain closing of tilting/sliding roof (SHD) (with code (414) Power glass tilting/sliding sunroof and code (345) rain sensor)

- Decouple on-board electrical system battery and activate additional battery (with code (B03) ECO start/stop function)

Actuation of components

The actuation of the components takes place via the following connections:

- Direct line

- Instrument panel LIN

- Wiper/inside rearview mirror LIN

Direct line

The following components are actuated over direct lines by the processor responsible for controlling the basic functions:

- A/C compressor regulation valve (A9y1) (without code (B09) A/C compressor with magnetic clutch)

- A/C compressor regulation valve (A9/7y1) (with code (B09) A/C compressor with magnetic clutch)

- A/C compressor magnetic clutch (A9/7y2) (with code (B09) A/C compressor with magnetic clutch)]

- Left front lamp unit (E1)

- Right front lamp unit (E2)

- As of 1.12.09 with code (621) Intelligent light system (left-hand traffic) or code (622) Intelligent light system (right -hand traffic) and without code (498) Japan version

- Left daytime running lights headlamp (E1/3)

- Right daytime running lights headlamp (E2/3)

- Up to 30.11.09 and as of 1.12.09 without code (621) Intelligent light system (left-hand traffic) and without code (622) Intelligent light system (right -hand traffic) or with code (498) Japan version

- Left front fog lamp (E5/1)

- Right front fog lamp (E5/2)

- With code (494) Canada version or code (460) USA version

- Left front side marker lamp (E6/1)

- Right front side marker lamp (E6/2)

- With code (954) Avantgarde or code (955) Elegance

- Left center vent symbol illumination (E10/1)

- Left front side air vent symbol illumination (E10/2)

- Right front side vent symbol illumination (E10/3)

- Right center air vent symbol illumination (E10/4)

- Rear vent symbol illumination (E10/5)

- Right front footwell lamp (E17/15)

- Left front footwell lamp (E17/16)

- Glove compartment lamp (E13/1) (switched via the glove compartment lamp switch (S17/9))

- As of 1.6.12 for model 204.9:

- Driver instrument panel ambiance illumination (E43/7)

- Front passenger instrument panel ambiance illumination (E43/8)

- Left fanfare horn (H2)

- Right fanfare horn (H2/1)

- With code (B03) ECO Start-stop function

- Decoupling relay (F32k1)

- Additional battery relay (K57/2)

- Windshield washer system pump (M5/1)

- With code (600) Headlamp cleaning system

- Headlamp cleaning system pump (M5/2)

- Coolant circulation pump (M13/5)

- Spray nozzle heater (R2/1)

- With code (875) heated windshield washer system:

- Spray nozzle hose heater (R2/11)

- With code (301) Ashtray package/smoker package:

- Ashtray illumination (R3e1)

- With engine 272 with code (494) USA version:

- Purging switchover valve (Y58/1)

- With engine 272 without code (494) USA version:

- Activated charcoal canister shutoff valve (Y58/4)

Instrument panel LIN

The following components are actuated via the instrument panel LIN:

- Exterior lights switch (up to 31.5.10) (Function feedback)

- Instrument panel switch group (function feedback)

- Upper control panel control unit (function feedback)

Wiper/inside rearview mirror LIN

The following components are actuated via the wiper LIN:

- Inside rearview mirror

- Garage door opener

- Wiper motor (M6/1)

Thursday, May 5th, 2022 AT 9:52 AM