Welcome back:

It comes as a unit. Here are the directions for replacement. The attached pics correlate with the directions.

__________________________________________________________

Change Vehicle Bookmarks Library Request Conversion Calculator Technician's Reference - Collision

fuel pressure regulator

32

Community 17 Create Quote

2014 Ford Fusion FWD L4-1.5L Turbo

High-Pressure Fuel Pump

Vehicle Powertrain Management Fuel Delivery and Air Induction Fuel Pump Service and Repair Removal and Replacement High-Pressure Fuel Pump

HIGH-PRESSURE FUEL PUMP

High-Pressure Fuel Pump

Materials

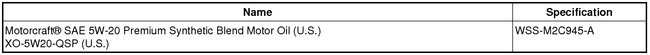

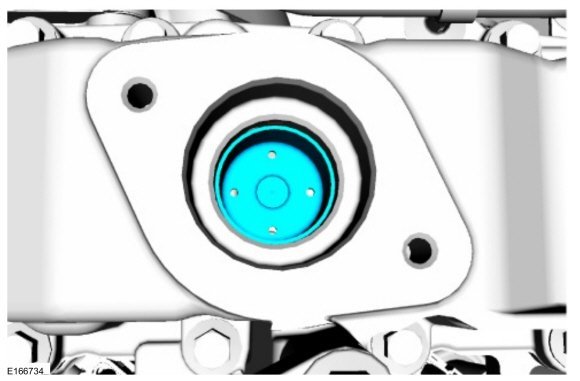

pic 1

Removal

NOTICE: Do not loosen any fittings or plugs on the high-pressure fuel pump.

1. Refer to: Fuel System Pressure Release See: Fuel Pressure Release > Procedures > Fuel System Pressure Release (310-00A Fuel System - General Information - 1.5L EcoBoost (118kW/160PS), General Procedures).

2. Refer to: Battery Disconnect and Connect See: Battery > Procedures > Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

3.

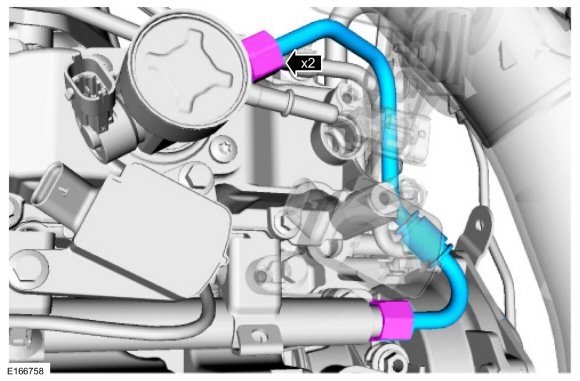

1. Refer to: Spring Lock Couplings See: Fuel Line Coupler > Procedures > Spring Lock Couplings (310-00A Fuel System - General Information - 1.5L EcoBoost (118kW/160PS), General Procedures).

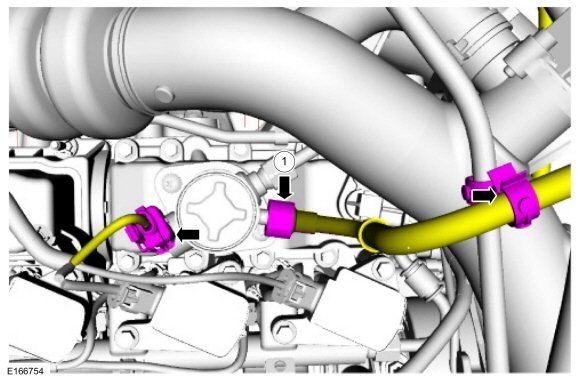

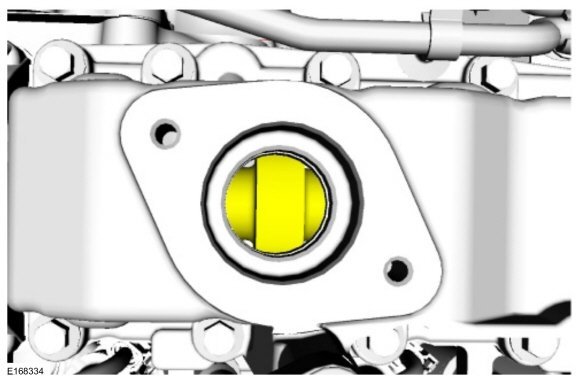

Pic 2

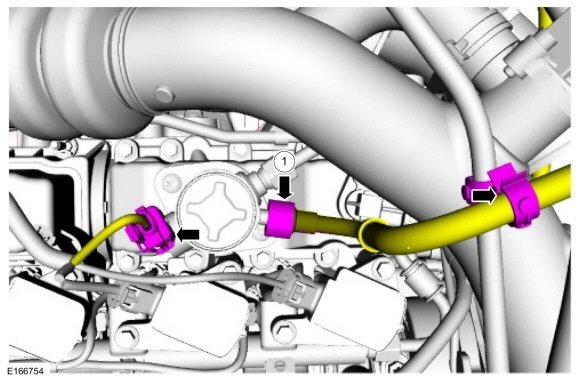

4. NOTICE: To release the fuel pressure in the high pressure fuel tube, wrap the high-pressure fuel pump flare nut with a shop towel to absorb any residual fuel pressure during the loosening of high-pressure fuel pump flare nut.

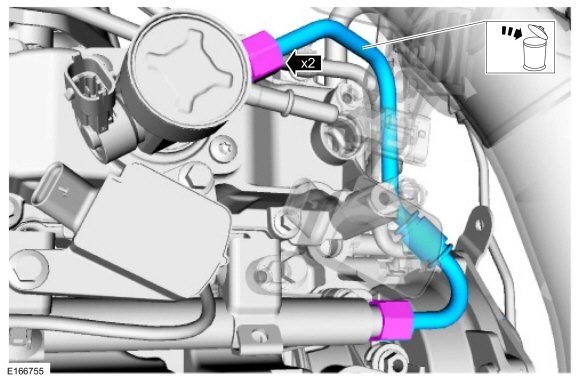

Pic 3

5. NOTE: Alternately loosen the 2 high-pressure fuel pump bolts one complete revolution at a time.

Pic 4

6.

Pic 5

7. If any flat spots or scoring are found, especially in the indicated areas, then inspect the high-pressure fuel pump and the high-pressure fuel pump tappet drive lobe. Install new components as necessary.

Pic 6

Installation

1. NOTE: The cam lobe for the high-pressure fuel pump must be at BDC (bottom dead center) for the high-pressure fuel pump installation.

Pic 7

2. NOTICE: Only rotate the crankshaft Clockwise (CW) or damage to the engine may occur.

Pic 8

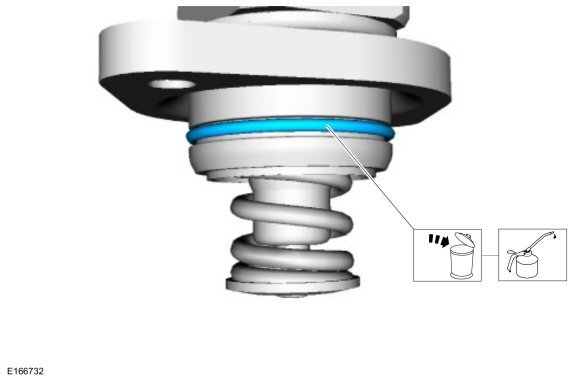

3. Material : Motorcraft(R) SAE 5W-20 Premium Synthetic Blend Motor Oil (U.S.)/ XO-5W20-QSP (U.S.) (WSS-M2C945-A)

pic 9

4. Make sure that a new high-pressure fuel pump O-ring is installed.

Material : Motorcraft(R) SAE 5W-20 Premium Synthetic Blend Motor Oil (U.S.)/ XO-5W20-QSP (U.S.) (WSS-M2C945-A)

pic 10

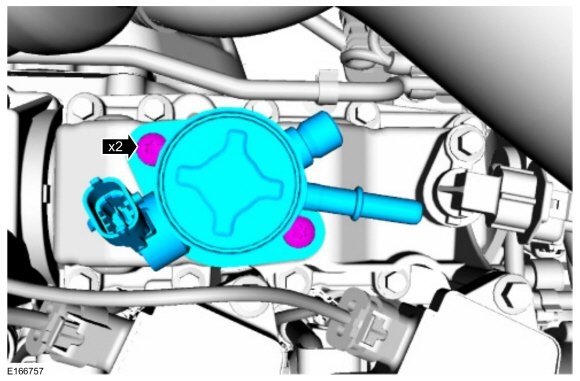

5. NOTE: Make sure that 2 new high-pressure fuel pump mounting bolts are installed.

1. Install the high-pressure fuel pump and loosely install the 2 high-pressure fuel pump bolts, alternately tighten each bolt 90° at a time in turn until the torque is achieved

Torque : 80 lb. In (9 Nm)

pic 11

6. NOTE: Only tighten the 2 high pressure fuel tube flare nuts finger tight at this stage.

NOTE: Make sure that a new high pressure fuel tube is installed.

NOTE: Calculate the correct torque wrench setting for the following torque using the Torque Wrench Adapter Formulas.

Torque :

Stage 1: 15 lb. Ft (21 Nm)

Stage 2: Wait 5min

Stage 3: 15 lb. Ft (21 Nm)

pic 12

7.

1. Refer to: Spring Lock Couplings See: Fuel Line Coupler > Procedures > Spring Lock Couplings (310-00A Fuel System - General Information - 1.5L EcoBoost (118kW/160PS), General Procedures).

Pic 13

8. Refer to: Battery Disconnect and Connect See: Battery > Procedures > Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

9. Refer to: Fuel System Pressure Release See: Fuel Pressure Release > Procedures > Fuel System Pressure Release (310-00A Fuel System - General Information - 1.5L EcoBoost (118kW/160PS), General Procedures).

__________________________________________________

Let me know if this helps.

Joe

Images (Click to make bigger)

Wednesday, September 25th, 2019 AT 6:20 PM