SECTION 6A9 - REVISED CAMSHAFT TIMING PROCEDURE -1991 Pontiac Grand.

Page 1 of 5

SECTION 6A9 - REVISED CAMSHAFT TIMING PROCEDURE

TECHNICAL SERVICE BULLETIN

Reference Number(s): 47-61-34, � Date of Issue: � December, 1994 Related Ref Number(s): 47-61-34

ARTICLE BEGINNING

REVISED CAMSHAFT TIMING PROCEDURE - SMU - SECTION 6A9

Model(s): 1991-95 Chevrolet Lumina

1995 Chevrolet Monte Carlo

1991-95 Oldsmobile Cutlass Supreme

1991-95 Pontiac Grand Prix

with 3.4L Engine (VIN X - RPO LQ1)

Section: 6 - Engine

Bulletin No: 47-61-34

Date: December, 1994

SERVICE INFORMATION

The following camshaft timing procedure replaces the information in the published service manual. Use this new procedure to properly time the engine.

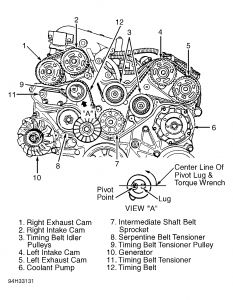

See camshaft timing procedure. See Fig. 1 through 3

TOOLS REQUIRED

TOOLS REQUIRED Part Number J38613-A J38614

REMOVE OR DISCONNECT

1. Negative battery cable. 2. Air cleaner assembly. 3. Drain engine coolant. 4. Accelerator and cruise control cables from throttle body.

Description Camshaft Timing Clamps Camshaft Sprocket Remover

SECTION 6A9 - REVISED CAMSHAFT TIMING PROCEDURE -1991 Pontiac Grand.

Page 2 of 5

5. Fuel rail cover. 6. Relieve fuel pressure. 7. Fuel lines from fuel rail and remove fuel mounting bracket. 8. Heater hose and bracket from lower intake manifold. 9. PCV valve and vacuum line from throttle body. 10. Electrical connector from EGR. 11. EGR valve and reposition. 12. Electrical connections from canister purge solenoid and MAP sensor. 13. Vacuum lines from upper intake manifold tee. 14. Wiring loom bracket for rear spark plug wires. 15. Power brake vacuum hose and remove upper intake manifold. 16. Coolant recovery tank. 17. Serpentine belt. 18. Serpentine belt tensioner. 19. Power steering lines from pump and reposition for pump removal. Refer to section 3B. 20. Reposition PCM (1991-93 ONLY). 21. PCM mounting bracket (1991-93 ONLY). 22. PCM electrical connectors and reposition (1994-95 ONLY). 23. Spark plug wires from spark plugs. 24. Wiring harness cover at right strut tower. 25. Fuel line bracket. 26. Timing belt covers. 27. Breather hose from rear camshaft cover and crankcase vent from breather manifold. 28. Camshaft carrier covers. 29. Side plate bolts from actuator. 30. Rotate actuator assembly from the tensioner pulley socket and out of the mounting base. 31. Timing belt tensioner pulley. 32. Position actuator in vertical position in vise (rod tip down), clamp actuator body in vise lightly. See Fig. 1

NOTE: Allow oil to drain to boot end for at least 5 minutes prior to refilling. The actuator assembly uses a tapered bushing between the actuator and mounting base. Do not lose or damage the bushing when removing the actuator assembly.

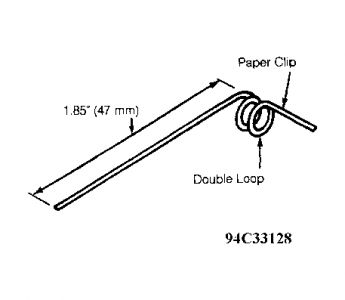

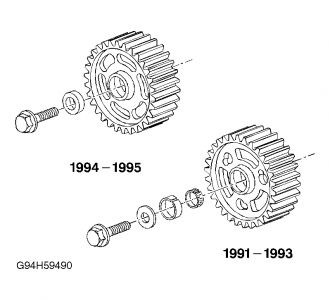

Fig. 1: Timing Belt Tensioner Actuator

33. Straighten out a standard paper clip (0.032 inch diameter, NO SERRATIONS) to minimum straight length of 47 mm (1.85 inches). Form a double loop in the remaining end of the paper clip. 34. Rubber end plug from the rear of the actuator assembly. The assembly is filled with oil and removal of the plug may allow oil to escape. ** DO NOT REMOVE VENT PLUG.**

SECTION 6A9 - REVISED CAMSHAFT TIMING PROCEDURE -1991 Pontiac Grand.

Page 3 of 5

35. Push the paper clip through the center of the vent plug and into the pilot hole. 36. Insert a small screwdriver into the screw slot inside the actuator, behind the rubber end plug. 37. Retract actuator plunger by rotating screw in a clockwise direction, until it is fully retracted. Push on paper clip and slowly rotate screw counterclockwise until paper clip engages. 38. Timing belt.

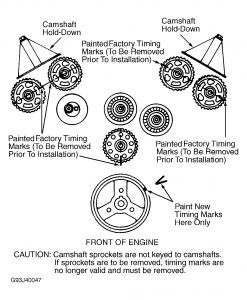

NOTE: Remove timing marks from camshaft and intermediate shaft sprockets.

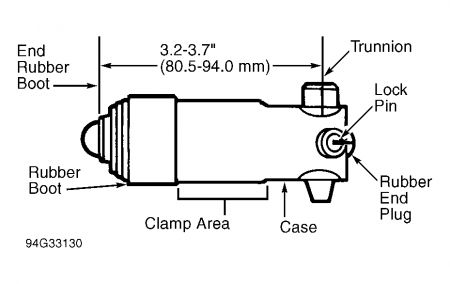

39. Rotate crankshaft so the #1 cylinder is at TDC (Top Dead Center). - Mark the timing indicator with white paint (or equivalent) on the crankshaft balancer and front cover.

Fig. 2: Crankshaft Reference Marks

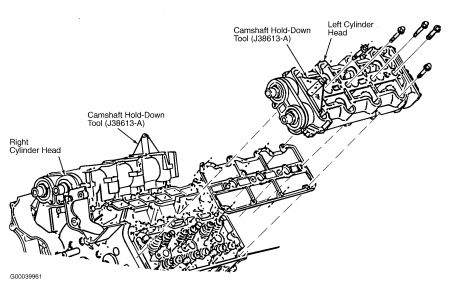

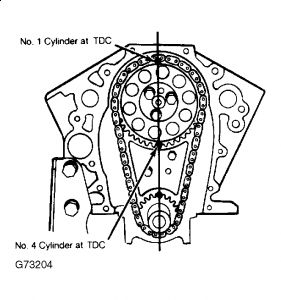

40. Position camshafts so the flat spots are "UP" for installation of J38613-A. 41. Install J38613-A on both camshaft carriers. 42. Camshaft sprockets. See Fig. 2.

- 1991-93 REMOVE BOLTS, WASHERS, AND SPROCKETS USING J38614.

- 1994-95 REMOVE BOLTS, TAPER LOCK RINGS, AND SPROCKETS BY LIGHTLY TAPPING ON IT WITH A SOFT FACED HAMMER.

Fig. 3: Camshaft Timing Sprockets

INSTALL OR CONNECT

1. Camshaft sprockets. - 1991-93 Camshaft sprockets with washers and new locks finger tight. - 1994-95 Camshaft sprockets with taper lock rings finger tight. 2. Timing belt in a counterclockwise direction around the sprockets.

NOTE: Make sure timing belt teeth are fully engaged with all sprockets.

3. Timing belt tensioner pulley. Tighten: Tensioner pulley bolt to 50 N.M (37 Ft-Lbs). 4. If actuator oil has been lost, fill the actuator with SAE 5W30 Mobil 1 (or equivalent) synthetic engine oil through the end hole. Fill to bottom of plug hole only when actuator is fully retracted and pin is installed. 5. Rubber end plug to rear of the actuator assembly. - Push until flush and snapped into place. - Make sure the end plug has sealed against the case. 6. Actuator bushing into side plate. INSPECT: Bushings and appropriate holes to make sure they are clean. DO NOT LUBRICATE. 7. Timing belt actuator and actuator side plate. TIGHTEN: Side plate bolt to 27 N.M (20 Ft-Lbs).

NOTE: Rotate pulley assembly into belt a maximum of 15 N.M to allow engagement of the actuator shaft into the pulley arm socket.

SECTION 6A9 - REVISED CAMSHAFT TIMING PROCEDURE -1991 Pontiac Grand.

Page 4 of 5

8. Pull the lock pin and discard. Retorque pulley assembly 15 N.M counterclockwise to seat pulley into belt. TIGHTEN: Both right hand (rear bank) camshaft sprocket bolts to 130 N.M (96 Ft-Lbs). 9. Remove J38613-A from right hand (rear bank) camshaft carrier. 10. Rotate crankshaft 360 degrees clockwise while looking at front at engine and align crankshaft reference marks. INSPECT: Make sure both right hand (rear bank) camshaft flats are down. TIGHTEN: Both left hand (front bank) camshaft sprocket bolts to 130 N.M (96 Ft-Lbs). 11. Remove J38613-A from left hand (front bank) camshaft carrier. 12. Rotate crankshaft 720 degrees clockwise while looking at front of engine to seat timing belt and verify correct timing. INSPECT: Make sure both camshaft flatspots are up on one bank and down on the opposing bank. 13. Camshaft carrier covers and bolts. TIGHTEN: Bolts to 11 N.M (97 INCH Lbs). 14. Breather hose from rear camshaft cover and crankcase vent from breather manifold. 15. Timing belt covers and bolts. TIGHTEN: Bolts to 10 N.M (89 INCH Lbs). 16. Fuel line bracket and bolt. TIGHTEN: Bolt to 7 N.M (62 INCH Lbs). 17. Wiring harness cover at right strut tower. 18. Spark plug wires. 19. PCM electrical connectors. 20. Power steering lines to pump. 21. Serpentine belt. 22. Serpentine belt tensioner. TIGHTEN: Serpentine belt tensioner bolt to 45 N.M (33 Ft-Lbs). 23. Coolant recovery tank. 24. Upper intake manifold, bolts, and nuts. TIGHTEN: Bolts and nuts to 27 N.M (22 Ft-Lbs). 25. Power brake vacuum hose. 26. Wiring loom bracket for rear spark plug wires. 27. Vacuum lines to upper intake manifold tee. 28. Electrical connections to canister purge solenoid and MAP sensor. 29. EGR valve and bolts. TIGHTEN: Bolts to 25 N.M (18 Ft-Lbs). 30. Electrical connectors from EGR. 31. PCV valve and vacuum line to throttle body. 32. Heater hose and bracket to lower intake manifold. Refer to Section 6B. 33. Fuel mounting bracket and bolt. 34. Fuel lines to fuel rail. Refer to Section 6C. 35. Fuel rail cover. Refer to Section 6C. 36. Accelerator and cruise control cables to throttle body. 37. Air cleaner assembly. Refer to Section 6E3-C14. 38. Refill cooling system. Refer to Section 6B. 39. Refill power steering system. Refer to Section 3B. 40. Negative battery cable.

SECTION 6A9 - REVISED CAMSHAFT TIMING PROCEDURE -1991 Pontiac Grand.

Page 5 of 5

Labor Operation: J0800

Labor Time: 3.8 HOURS - 1991-93

3.1 HOURS - 1994-95

Wednesday, October 7th, 2020 AT 11:47 AM

(Merged)