My car is the 2.4L. When idling in drive with the A/C on and sitting still at a light, the whole car shakes. The steering wheel vibrates, the floor vibrates, and the dash shakes up and down. The engine is at 600 rpm under these conditions, and if raised slightly to around 750 or so, the shakes go away. If you put the transmission into neutral or reverse, the shake will also go away. If you turn the A/C off, the shake is still there, but much less so.

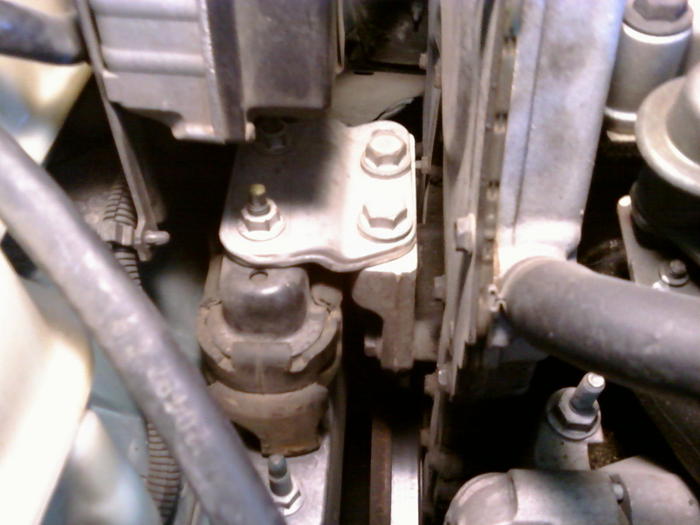

I checked the motor and transmission mounts, and found the front transmission mount cracked. I replaced it, but the shake is still there. I also noticed that when I drive into the driveway, which has a slight uphill slope, and park with the trans in drive the shake is there. Put it into neutral, or reverse, it is gone. When in park it is gone, until you take your foot off the brake pedal. At that point the car coasts back slightly until the transmission is holding the car, and the vibration comes back. This had me convinced that the front trans mount was the culprit, but as I said, replacing it made no difference.

The engine runs fine otherwise, and performs well under acceleration. There is no check engine light or codes. It is not a problem in the tires, wheel bearings, suspension, or any of that, because it only does it sitting still.

Is it possible that the rear transmission mount has gotten weak with age? It looks okay, and does not have any cracks that I can see, but is the only logical answer that I can come up with. If it was anything in the engine itself causing the shakes, why would it only do it in park once the transmission is holding the car? The driveway only has a slight incline, but it is enough for the car to roll back if put in neutral. Putting it in park does put slight pressure on the trans mount, but not much.

I would just change the rear mount, but it is $60.00, and does not look to be any fun to get to either. I am sure that this is not a normal condition, and that someone else has already had the same problem. Hopefully that person will be willing and able to help me. Thanks in advance.

Friday, May 7th, 2010 AT 7:00 PM