KICKDOWN BAND

31TH Transaxle

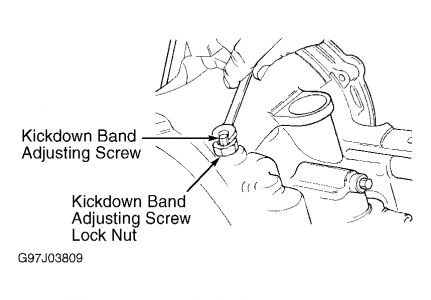

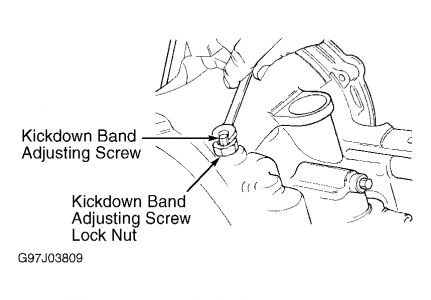

1.Kickdown band is also known as front band. Loosen kickdown band adjusting screw lock nut while preventing kickdown adjusting screw from rotating. Kickdown band adjusting screw is located on top front side of transaxle. See Fig.

.

2.Back off kickdown band adjusting screw lock nut 5 turns. Ensure kickdown band adjusting screw rotates freely in transaxle case.

3.Tighten kickdown band adjusting screw to 72 INCH lbs. (8.1 N.m). Back off kickdown band adjusting screw 2 1/4 turns. Hold kickdown band adjusting screw in this position and tighten adjusting screw lock nut to specification.

.

LOW-REVERSE BAND

31TH Transaxle

1.Low-reverse band is also known as rear band. Oil pan must be removed from transaxle to adjust low-reverse band. Raise and support vehicle. Loosen oil pan bolts. Tap on one corner of oil pan to loosen. Allow fluid to drain. Remove oil pan bolts and oil pan.

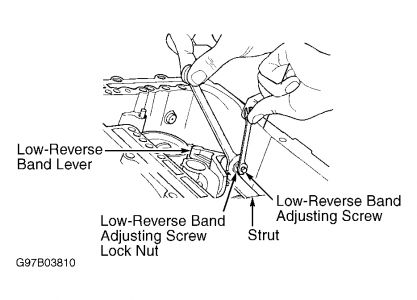

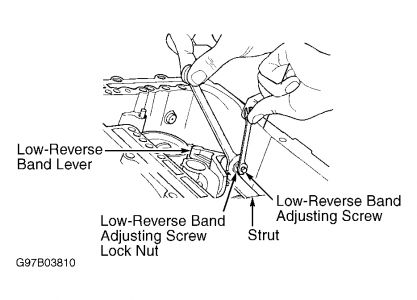

2.Loosen low-reverse band adjusting screw lock nut while preventing low-reverse band adjusting screw from rotating. Low-reverse band adjusting screw lock nut and low-reverse band adjusting screw are located inside transaxle, near low-reverse band lever. See Fig.

3.Back off low-reverse band adjusting screw lock nut 5 turns. Ensure low-reverse band adjusting screw rotates freely in transaxle case.

4.Tighten low-reverse band adjusting screw to 41 INCH lbs. (4.6 N.m). Back off low-reverse band adjusting screw 3 1/2 turns. Hold low-reverse band adjusting screw and tighten low-reverse band adjusting screw lock nut to specification.

5.Clean oil pan, magnet and all sealing surfaces. Apply RTV sealant on sealing surfaces of oil pan. Install oil pan. Install and tighten oil pan bolts to specification.

6.Add 4.0 Qts. (3.8L) of MOPAR ATF Plus 3, Type 7176 fluid to transaxle. Apply parking brake. Start engine and allow it to idle for at least one minute. With brakes applied, shift transaxle through all gears, ending in Park.

7.Add additional fluid to bring level 1/8" below ADD mark on dipstick. Recheck fluid level with transaxle at normal operating temperature. Adjust fluid level within HOT range on dipstick. DO NOT overfill.

SPONSORED LINKS

Sunday, November 16th, 2008 AT 6:29 PM