I am visiting family out of town and I need to resolve this to get back home by the end of next week. This will be a twelve hour drive and I fear breaking down on the highway.

Four days ago my truck listed above (L4) started in a store parking lot and got me to my mom’s home, but the dash and head lights were dimmed, the radio cycled down multiple times and the battery light came on and the dash volt meter showed about ten volts. I verified this with my Fluke 83 DVOM, but had to stop as it was getting dark and starting to rain.

The next morning with meter and amp probe in hand I started the truck up and showed 13.2 volts at the alternator with a 0.075vdp to the battery and a 58.5A draw to run all of the trucks accessories and charge the battery. Within five minutes the voltage rose to 14.1 volts and the amps dropped to 30 amp with most of the accessories turned off.

After shutting down the engine and restarting the truck the battery light, gauge and meter all confirm the truck voltage was 12.2 volts and dropping with no output current from the alternator. I shut down the engine at 11.5 volts. After a few hours the truck was restarted with the alternator’s output returning to normal.

I have been able to duplicate this cycle four times in three days.

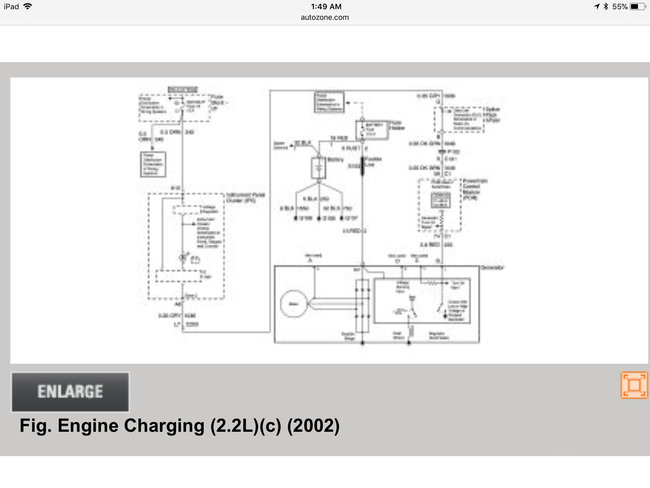

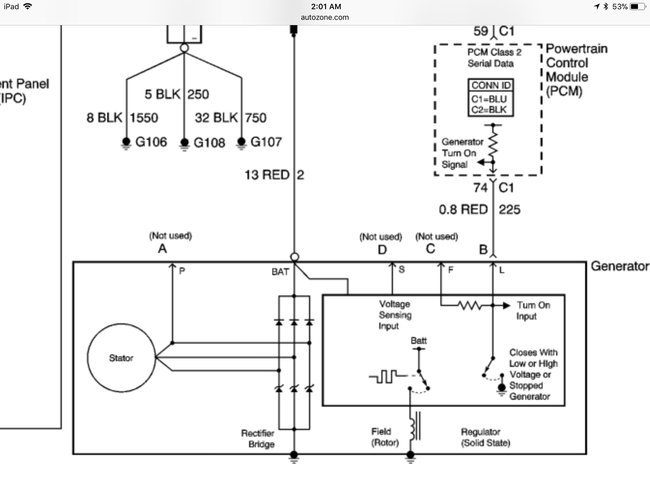

After finding and downloading a schematic as best I can determine the single sixteen gauge wire coming off the alternator only tells the alternator “when” to charge and not “how much” as the voltage is a constant 4.70 volts input when the alternator is charging, and drops to less than 1.5 volts when the truck is hot and restarted with no output from the alternator.

My questions are: Am I correct about how this charging system works? Are there any inputs to the PCM that should trigger the PCM to turn off the alternator under these conditions, and what should I look for? Has the PCM fail and can I verify it?

Sorry for the lengthy story, but I have worked in the diesel industry in Customer, Tech, and Dealer support. And I have always hated when people call me to tell them what part to replace with minimal details and no troubleshooting trail as if I had a crystal ball.

Thursday, January 11th, 2018 AT 10:46 AM