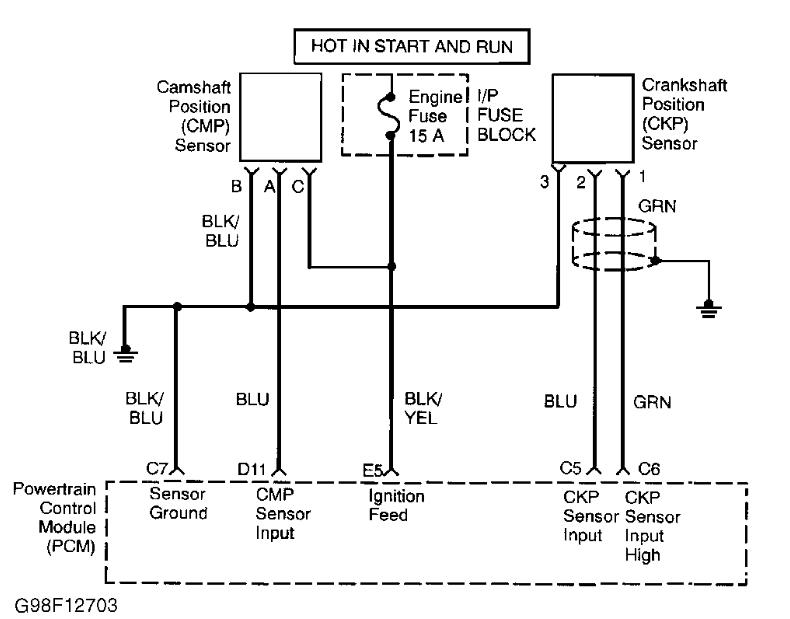

It could be a bad connector or a wire hitting someplace against the block or partially grounding out. Have you done the simple stuff like check the ecm main relay as that may not be supplying enough power to pcm to begin with. You should have battery voltage on one of the cmp connections so if it's not then there may be a short in harness or the ecm main relay isn't working very well and causing this. What were the original codes anyhow as you just started giving figures of voltage readings. Here is the way to check cam sensor power which you already have the pic I sent earlier if there is not up to snuff that is probably your problem but check the ecm main relay first.

Perform On-Board Diagnostic II (OBD-II) system check. See TESTS W/CODES-INTRODUCTION article. Go to next step.

Turn ignition on. Using scan tool, read and record FAILURE RECORDS data for DTC P0341. Operate vehicle within conditions noted in FAILURE RECORDS data. Using scan tool, read SPECIFIC DTC. If scan tool displays DTC P0341 FAILED THIS IGN, go to next step. If scan tool does not display DTC P0341 FAILED THIS IGN, see DIAGNOSTIC AIDS.

Using DVOM, backprobe PCM connector at CMP signal circuit. With sensor connected, crank engine and monitor voltage. If voltage toggles 0-4 volts, go to next step. If voltage does not toggle 0-4 volts, go to step 6).

Check for poor connection at PCM connector terminal D1. If a problem is found, repair as necessary. Retest system. If no problem is found, go to next step.

Replace PCM. Program replacement PCM using required equipment. See COMPUTER RELEARN PROCEDURES article in GENERAL INFORMATION section. Retest system.

Disconnect CMP sensor. Turn ignition on. Measure voltage at CMP sensor harness connector between sensor feed circuit and sensor ground circuit. If reading is about battery voltage, go to step 11). If reading is not as specified, go to next step.

Measure voltage between CMP positive connector at CMP sensor harness connector and ground. If reading is about battery voltage, go to step 9). If reading is not as specified, go to next step.

Repair open between PCM main relay and CMP sensor. Retest system.

Measure voltage between battery positive and CMP ground wire at CMP sensor harness connector. If reading is around battery voltage, go to step 11). If reading is not as specified, go to next step.

Repair open in ground circuit. Retest system.

Turn ignition off. Using DVOM, check continuity of signal wire between CMP sensor and PCM. If continuity does not exist, repair open signal wire. Retest system. If continuity exists, go to next step.

Turn ignition on. Check signal wire for short to ground or short to voltage. If problem is found, repair as necessary. Retest system. If no problem is found, go to next step

SPONSORED LINKS

Wednesday, April 2nd, 2014 AT 4:13 PM