Dandy reply, but please allow me to add a few comments of value. Normally I would say the worst way to test a generator is off the engine because that testing doesn't include the vehicle's wiring and in many cases the voltage regulator. Bench testers also aren't strong enough to drive generators to their maximum output capacity, and they don't check for "ripple" voltage.

This case is different in that the charging system can't be tested because the engine stalls. You eluded to the fact that jumper cables needed to be connected, but to continue the thought, that means it was the donor car that was under test.

The first thing to consider is the battery is totally discharged. When that happens, it can take a good 15 minutes before it starts to take a charge. It can take that long for the acid to become conductive, then the electrons begin to get absorbed into the plates. If you use a small portable charger on a low rate, you'll see the meter indicate near 0 amps for that first 15 minutes, then it will slowly start to rise. After a few hours, the battery can be considered to be fully-charged when the current drops below around 5 amps.

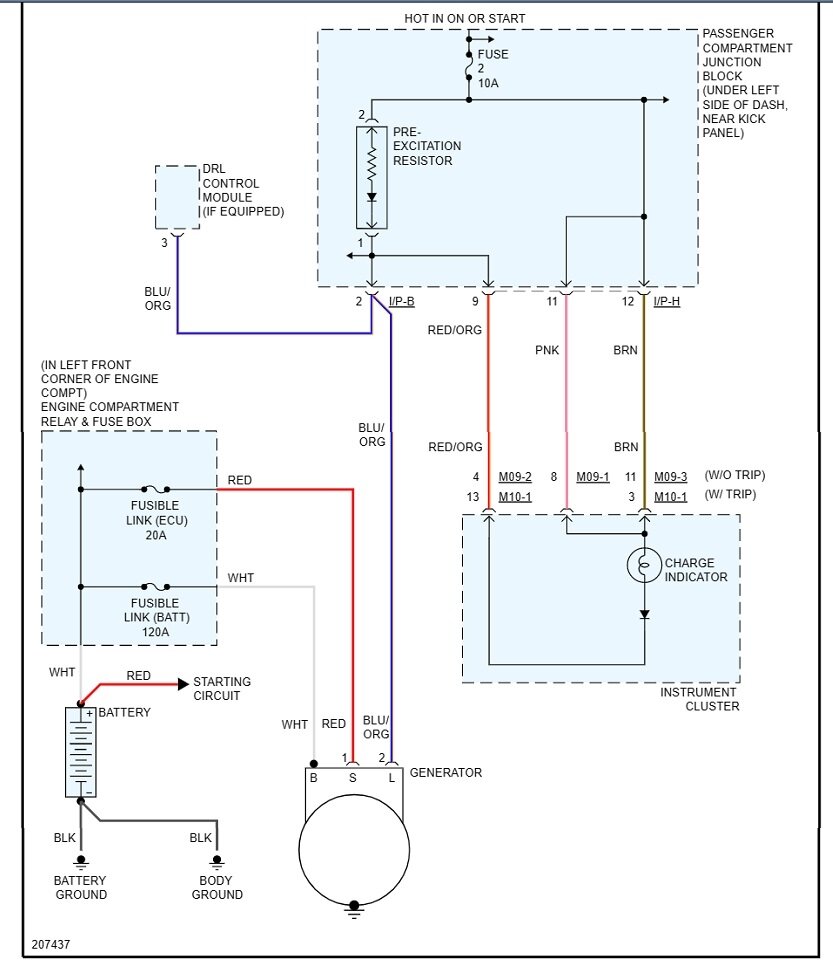

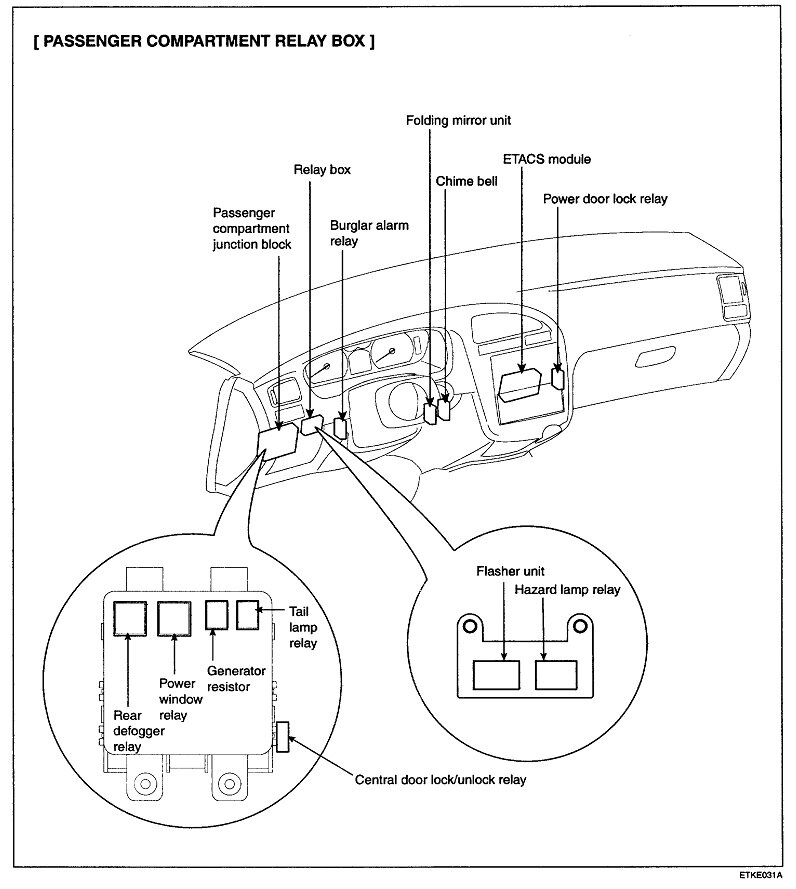

The next problem has to do with how the voltage regulator works. That varies between brands and models. Some will see the low battery voltage when the jumper cables are disconnected, and respond by shutting down. That means no output from the generator, so the engine stalls. On other models, the voltage regulator will get up and running with the jump start, then once they're disconnected, the regulator will see the low battery voltage, and make the generator run harder to produce higher voltage and more output current. I'll add one more comment related to this later.

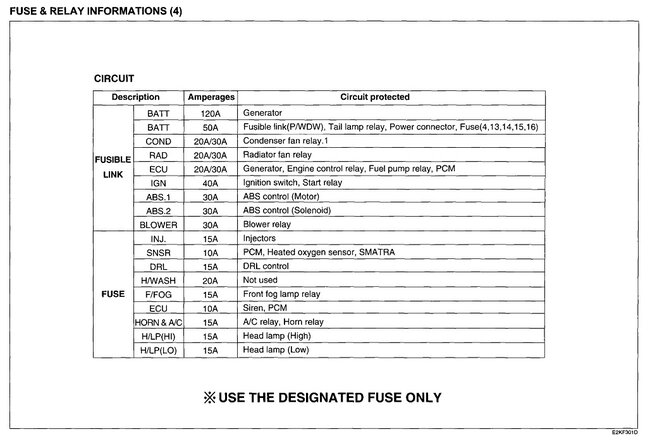

The next problem has to do with the "diodes" in all "AC Generators". (We all know what is meant by the word "alternator", but to be technically correct in the classroom, that is a Chrysler term. They developed the alternator for 1960 models and copyrighted the term). For the rest of us, the industry refers to them as "AC generators". Regardless, they all have at least six diodes which are one-way valves for electrical current flow. Generators put out three-phase output current which is very stable and efficient. The point of this sad story is if one diode fails, you'll lose one of those three phases, and the generator will lose exactly two thirds of its current-generating capacity. The standard generator for this model is a 90-amp unit. That means with a failed diode, all it will be able to develop is close to 30 amps. That's not enough to meet the demands of the entire electrical system under all conditions. The battery will have to make up the difference as it slowly runs down over days or weeks. If the battery is already run down, there won't be enough output from the generator to run the vehicle even if the voltage regulator did start up.

To add to the confusion, this is where a generator with a bad diode can still test "good" on a test bench. It takes about a one horsepower motor to run a generator supplying 30 amps on a test bench. To get full output from a properly working generator takes closer to five horsepower. Bench testers don't have electric motors that big.

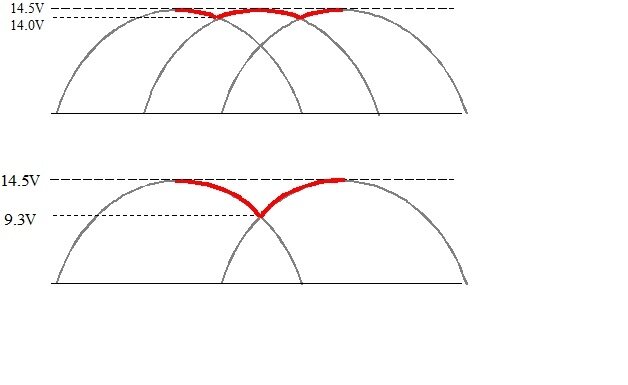

"Ripple" voltage refers to the unsteady output voltage, as shown in my first drawing. This generator will develop up to 90 amps with all good diodes, and ripple voltage for this example is shown as 0.5 volts, (red section). Below that, one phase is missing. Here again, the red section shows the output voltage that will be developed. Ripple voltage is 5.2 volts.

Professional load testers test charging systems on the car by measuring maximum output current and ripple voltage. Both are indications as to the condition of the diodes. A few testers that can make paper printouts will list an actual voltage for ripple voltage, but most testers just show it on a relative bar chart as "low" or "high".

The bottom line is bench testers don't measure ripple voltage and they aren't strong enough to drive a generator to its full output current capacity, so they can't show if the diodes are all good or not. This goes back to which way a voltage regulator works. Some will look at the low points in the output voltage, (9.3 volts in the lower drawing), and respond by bumping up the charging voltage. Some will look at the highest point, (14.5 volts), and cut back on generator output, often, again, to the point of stalling.

All of this should be eliminated by getting the battery fully charged first. Once that is done, this article explains how to start the charging system test:

https://www.2carpros.com/articles/how-to-check-a-car-alternator

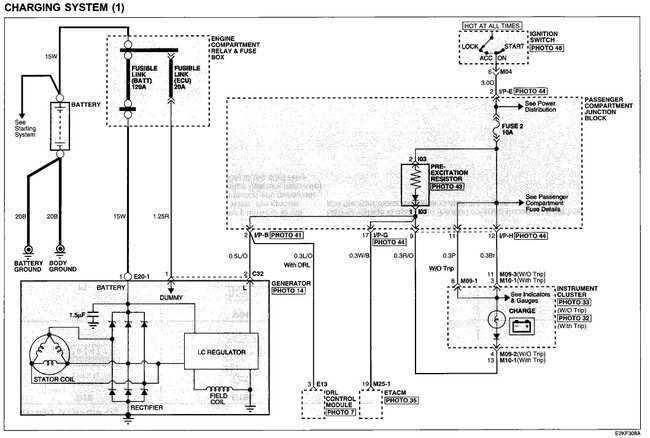

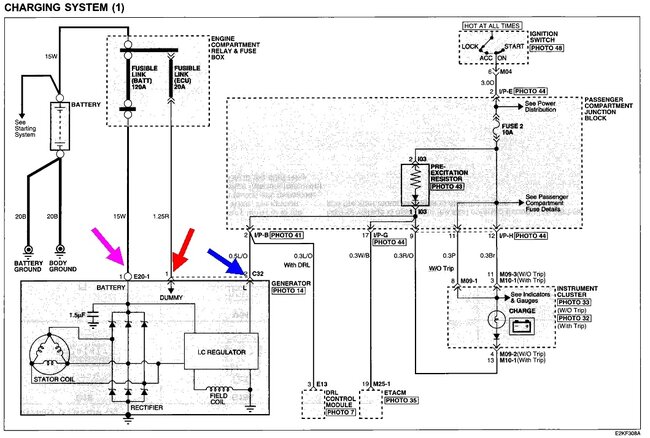

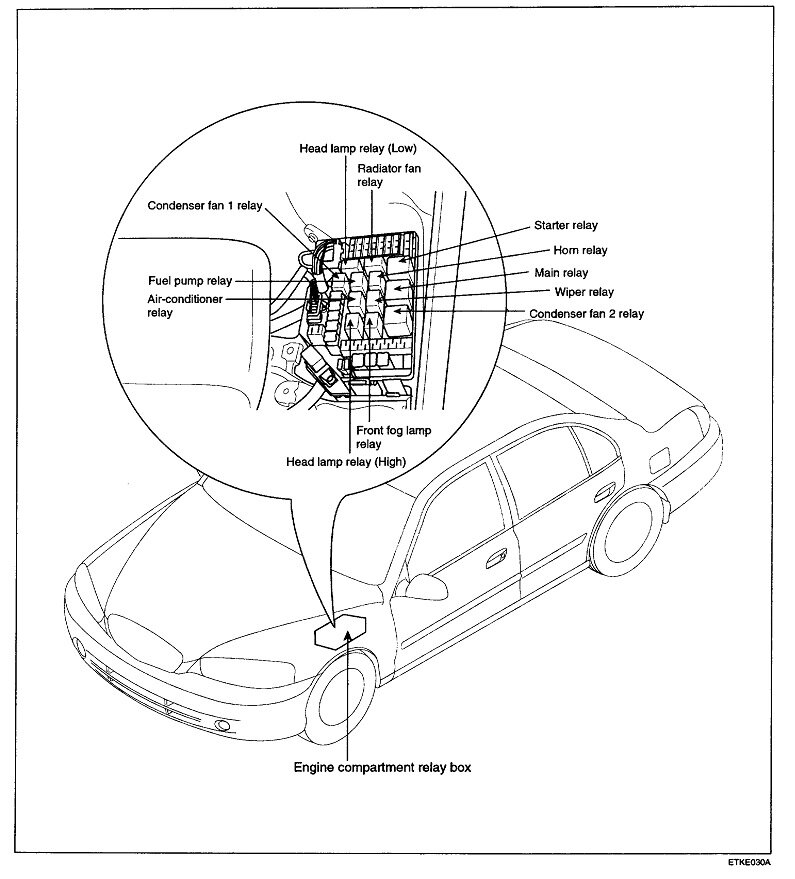

Doing this on the car includes the system voltage sensing circuit and the generator's output circuit. There's actually three different circuits that can cause a good generator to not work. If this charging voltage test is okay, it only means it is okay to continue with the rest of the tests, but those require the professional load tester.

I know that's a lot of information with not a definite answer. Let us know how you'd like to proceed or if you have more questions.

Image (Click to make bigger)

Thursday, March 2nd, 2023 AT 7:21 PM