Hi,

Is it possible for you to record the engine turning over so I can hear it? Since it sounds like it is turning too fast, it sounds like compression was lost. Although the timing belt looks good, it still could have jumped timing. If that happened, this is an interference engine and internal damage is likely.

THis video will help is fix it

https://youtu.be/vMwTzURWXmk

If you can't record it for me, I need you to check engine compression and let me know what you find. Here is a link that explains how it is done:

https://www.2carpros.com/articles/how-to-test-engine-compression

__________________

Here are directions specific to your vehicle which indicate what to expect. The attached pics correlate with the directions.

_________________

2008 Mitsubishi Eclipse L4-2.4L (4G69)

Compression Pressure Check

Vehicle Powertrain Management Tune-up and Engine Performance Checks Compression Check Testing and Inspection Component Tests and General Diagnostics Compression Pressure Check

COMPRESSION PRESSURE CHECK

COMPRESSION PRESSURE CHECK

Required Special Tool:

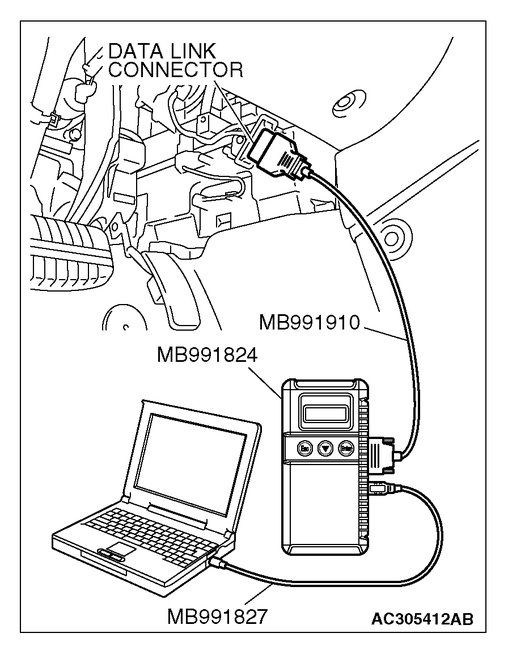

MB991958: Scan Tool (M.U.T.-III Sub Assembly)

MB991824: V.C.I.

MB991827: M.U.T.-III USB Cable

MB991910: M.U.T.-III Main Harness A

1. Before inspection, check that the engine oil, starter and battery are normal. Also, set the vehicle in the following condition:

Engine coolant temperature: 80-95° C (176-203° F)

Lights and all accessories: OFF

Transaxle: Neutral (P range on vehicles with A/T)

NOTE: On vehicles for Canada, the headlight, taillight, etc. remain lit even when the lighting switch is in "OFF" position but this is no problem for checks.

2. Remove all of the ignition coils and spark plugs.

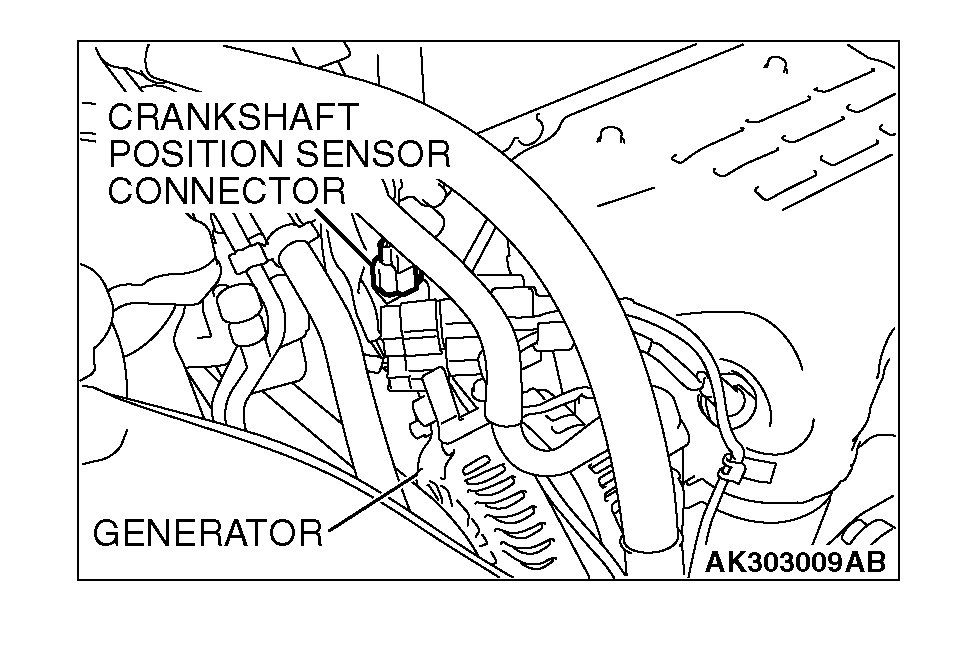

pic 1

3. Disconnect the crankshaft position sensor connector.

NOTE: Doing this will prevent the engine control module from carrying out ignition and fuel injection.

WARNING: Keep your distance from the spark plug hole when cranking. Oil, fuel, etc., may spray out from the spark plug hole and may cause serious injury.

4. Cover the spark plug hole with a shop towel etc., during cranking. After the engine has been cranked, check for foreign material adhering to the shop towel.

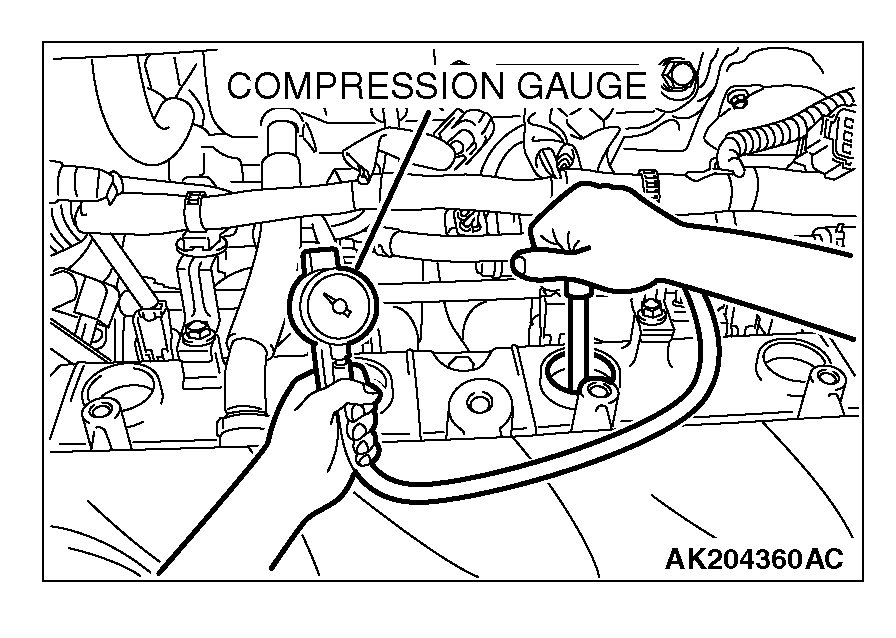

pic 2

5. Set a compression gauge to one of the spark plug holes.

6. Crank the engine with the throttle valve fully open and measure the compression pressure.

Standard value (at engine speed of 200 r/min): 1,560 kPa (226 psi)

Minimum limit (at engine speed of 200 r/min): 1,130 kPa (164 psi)

7. Measure the compression pressure for all the cylinders, and check that the pressure differences of the cylinders are below the limit.

Limit: 98 kPa (14 psi)

8. If there is a cylinder with compression or a compression difference that is outside the limit, pour a small amount of engine oil through the spark plug hole, and repeat the operations in steps 6 to 8.

(1) If the compression increases after oil is added, the cause of the malfunction is a worn or damaged piston ring and/or cylinder inner surface.

(2) If the compression does not rise after oil is added, the cause is a burnt or defective valve seat, or pressure is leaking from the gasket.

9. Connect the crankshaft position sensor connector.

10. Install the spark plugs and ignition coils.

pic 3

11. Use the scan tool MB991958 to erase the diagnostic trouble codes.

NOTE: This will erase the diagnostic trouble code resulting from the crankshaft position sensor connector being disconnected.

_________________________

Let me know.

Joe

Images (Click to make bigger)

Monday, April 27th, 2020 AT 10:46 AM