There shouldn't be 12 volts to the ignition coil except for two times. First is for one second when the ignition switch is turned to "run". Second is during engine rotation, (cranking or running). During cranking, the Engine Computer sees signal pulses from the camshaft position sensor, in this case the sensor under the rotor in the distributor, then it turns on the automatic shutdown, (ASD) relay. That relay sends current to the ignition coil(s), injectors(s), alternator field circuit, and the fuel pump or fuel pump relay.

I'm going to guess you have a crank / no-start problem. By far the most common cause is a failed Hall Effect pick-up assembly. There is likely to be a diagnostic fault code set for this, but they often don't set just from cranking the engine. Often more time is needed to detect the missing signal, as in when a stalling engine is coasting to a stop. Any fault codes will also be erased if the battery is disconnected or run down, then that valuable information will be lost.

Chrysler made reading fault codes yourself much easier than any other manufacturer. Cycle the ignition switch from "off" to "run" three times within five seconds without cranking the engine. Leave it in "run", then watch the code numbers appear in the odometer display. You can go here:

https://www.2carpros.com/trouble_codes/obd2

to see the definitions, or I can interpret them for you.

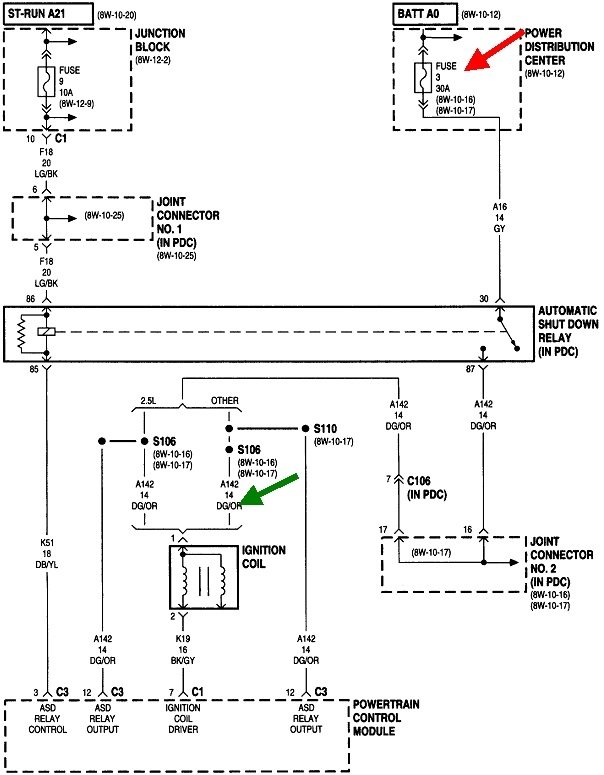

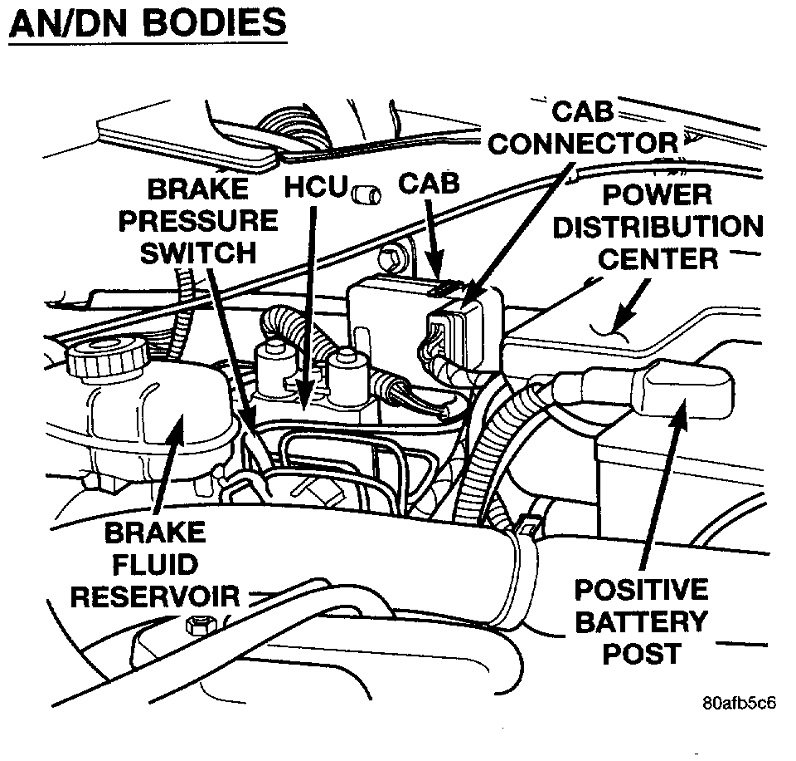

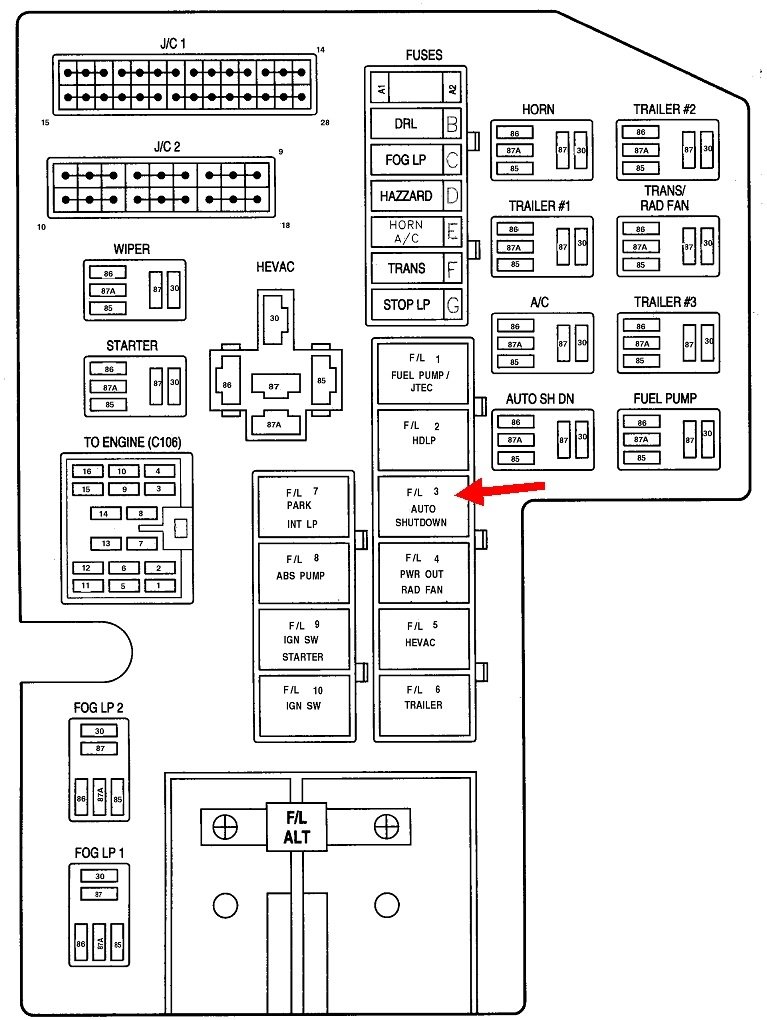

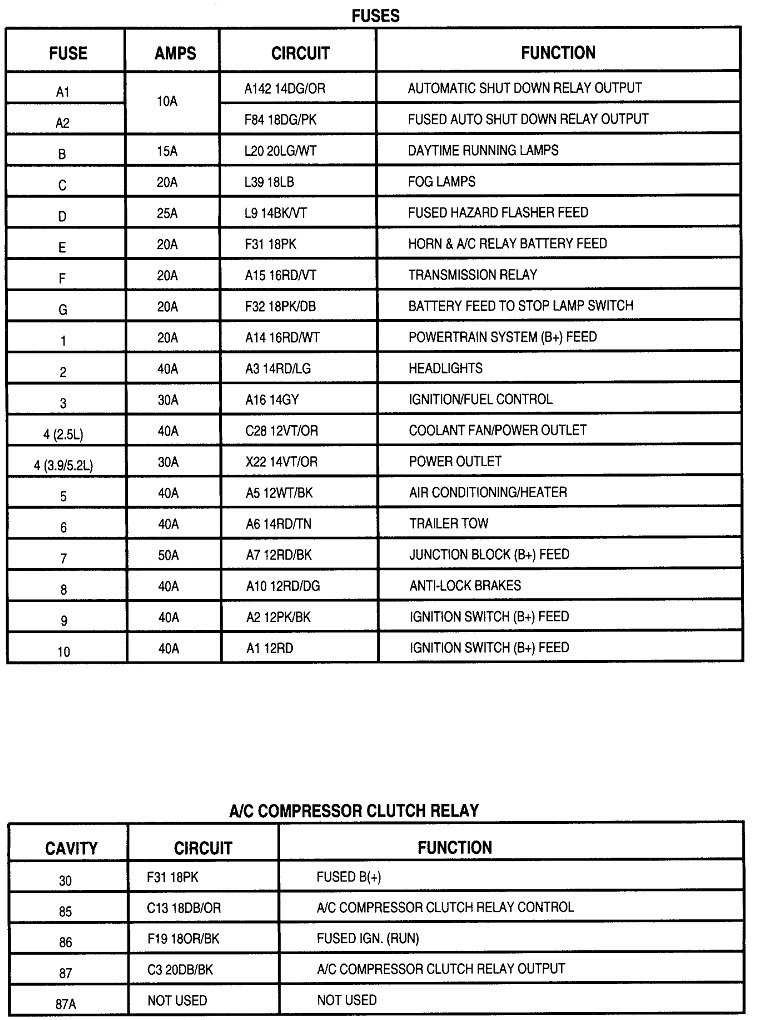

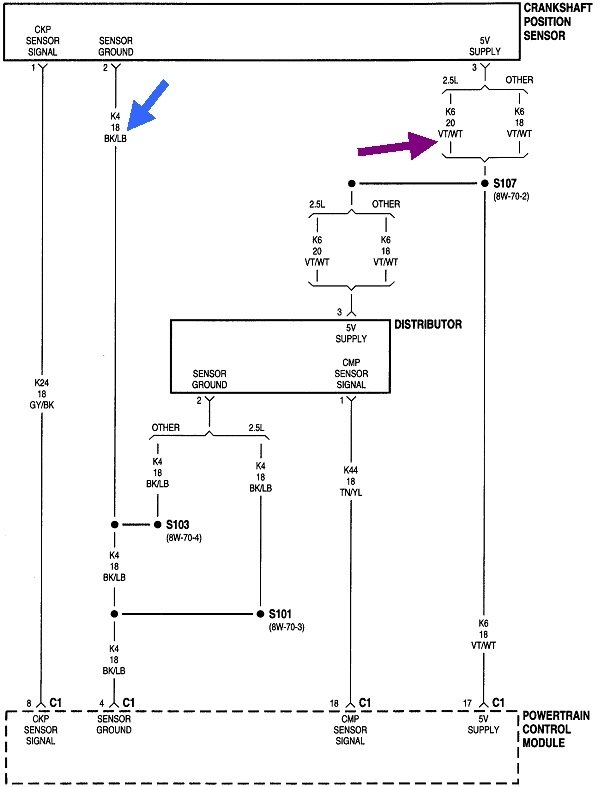

Whether or not a fault code has set related to the problem, a quick test is to check for 12 volts at the ignition coil, any injector, or either smaller terminal on the back of the alternator. You can use a digital voltmeter but most of them don't respond fast enough. A test light is a better choice for this test. Use the wire that is the same color at each of those places. On most Chrysler products that's a dark green / orange wire as shown with the green arrow in this diagram. Your test light should light up full brightness for one second when you turn on the ignition switch. In the rare event it does not, check fuse # 3 in the power distribution box, (under-hood fuse box). If that is blown, the best suspect is the wiring harness to an oxygen sensor has fallen down onto hot exhaust parts.

Next, the test light must turn on again when you're cranking the engine. If it doesn't, you can see the missing signal from the distributor on a scanner, but since this is so common, just replace the pick-up assembly. Many people carry a spare in the glove box. If you installed a used distributor, there's also a good chance it has a defective pick-up assembly.

Also be sure the distributor's shaft is turning. If it is not, the timing belt is broken or has missing teeth. This is not an interference engine, so no valves will have been damaged.

There's no easy way to test the crankshaft position sensor other than to check the supply voltages. There should be 5.0 volts on the violet / white wire. Expect to see 0.2 volts on the black / light blue ground wire. Beyond that, the best way to see if both sensor signals are showing up at the computer is to view live data on a scanner. Each one will be listed with a "No" or "Present" during cranking. I use a Chrysler DRB3 for all of my vehicles. Aftermarket scanners will have a similar way of showing this.

Let me know what you find up to this point including any fault codes.

Images (Click to make bigger)

SPONSORED LINKS

Sunday, February 13th, 2022 AT 2:11 PM