Have you checkk the BCDD? Heres how and what of it...

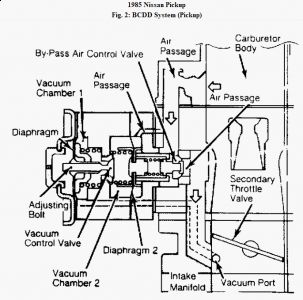

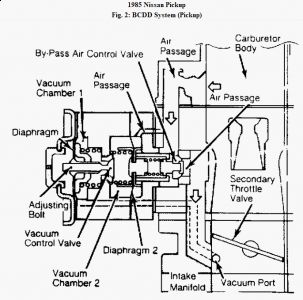

ARTICLE BEGINNING DESCRIPTION The Boost Controlled Deceleration Device (BCDD) is installed to control HC emissions during deceleration by reducing the engine's consumption of lubricating oil. The BCDD is mounted under the throttle chamber as an integral part. This device supplies additional air to the intake manifold to maintain manifold vacuum at proper operating pressure. OPERATION The Boost Controlled Deceleration Device (BCDD) contains 2 diaphragms. When vacuum in the intake manifold exceeds a pre-determined value, diaphragm No. 1 opens the vacuum control valve. This allows manifold vacuum into a vacuum chamber in the BCDD and actuates diaphragm No. 2. When actuated, diaphragm No. 2 opens the air control valve, allowing additional air into the manifold to maintain required operating pressure. The amount of air entering the manifold is controlled by the servo-action of the air control valve and vacuum control valve. This servo-action maintains manifold vacuum at the predetermined operating pressure. Fig. 1: BCDD System (Maxima) ADJUSTMENTS BCDD OPERATING PRESSURE 1. Turn adjusting mechanism as necessary until specified operating pressure is obtained. Turning the adjusting mechanism clockwise decreases operating pressure and counterclockwise increases pressure. 2. Turn adjusting mechanism in or out with lock spring in place. Also, always set lock spring properly to prevent changes in operating pressure. 3. After setting pressure to specification, accelerate engine and check adjustment. If lower than specified, turn adjusting mechanism until correct. 4. Accelerate engine again and check adjustment. If engine speed cannot be decreased to idle when checking BCDD operating pressure, proceed as follows: 5. Turn adjusting mechanism counterclockwise so BCDD operating pressure is .79 in. Hg higher than specification on Maxima models or .98 in. Hg higher than specification on Pickup models. 6. Turn adjusting mechanism 1/4 turn clockwise so pressure drops to specification on all models. If operating pressure cannot be observed in step 5), turn adjusting mechanism counterclockwise so BCDD operating pressure is 1.97 in. Hg higher than specification. 7. After setting pressure to specification, accelerate engine and check adjustment. If lower than specified, turn adjusting mechanism until correct. 8. Turn adjusting mechanism 1/2 turn clockwise so pressure drops to specification. If pressure cannot be adjusted, unit must be replaced as an assembly.COMPONENT TESTING BCDD OPERATING PRESSURE 1. To check pressure, engine should be at normal operating temperature, idle speed set to specifications and transmission in Neutral. Connect a tachometer to engine and a vacuum gauge to intake manifold. 2. Run the engine under no load and note vacuum reading. Increase engine speed to 3000-3500 RPM on Maxima models, or 2000 RPM on Pickup models, then quickly close the throttle. 3. Manifold vacuum should increase 23.6 in. Hg or more on Maxima models, or 24.0 in. Hg or more on Pickup models. Gradually decrease to idle level. Operating pressure should be 21.6- 23.2 in. Hg on Maxima and 23.8-24.2 in Hg. on Pickup. If pressures at idle are not to specification, proceed to ADJUSTMENTS . Fig. 2: BCDD System (Pickup)

NOTE: The BCDD operating pressure must be set to specifications after previous adjustment procedures, even if engine speed cannot be decreased to idling RPM.

Monday, March 16th, 2009 AT 1:26 PM