Hello .. thanks for the donation .. much appreciated

P0750 Shift Solenoid SL1

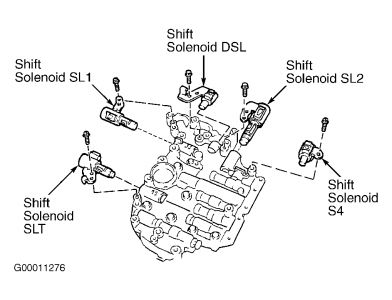

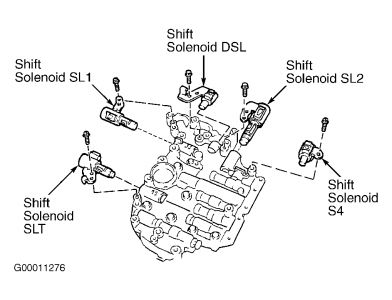

SHIFT SOLENOIDS SL1, SL2 & S4

NOTE:The following information can also be used to diagnose DTCs P0750, P0755 and P0765. For testing of shift solenoid SLT, see DTC P1760: SHIFT SOLENOID SLT under DIAGNOSTIC TESTS.

Raise and support vehicle. Remove transaxle oil pan. Remove shift solenoid(s). See Fig. 3 . Using a DVOM, measure resistance between shift solenoid SL1 and SL2 terminals. On shift solenoid S4, measure resistance between ground and solenoid terminal. On shift solenoids SL1 and SL2, resistance should be 5.1-5.5 ohms. On shift solenoid S4, resistance should be 11-15 ohms. On all solenoids, if resistance is not as specified, replace solenoid.

To check shift solenoids SL1 and SL2 operation, connect positive lead with 23-watt bulb from battery to terminal No. 1 (White wire on shift solenoid SL1, or Yellow wire on shift solenoid SL2) of solenoid. Connect negative lead to terminal No. 2 of solenoid. With power supplied to solenoid, ensure solenoid valve moves outward. With power disconnected, ensure solenoid valve moves inward. Replace solenoid if operating sound cannot be heard. If solenoid operates, diagnose valve body malfunction.

To check shift solenoid S4 operation, connect positive lead with 23-watt bulb from battery to solenoid terminal. Connect negative lead to solenoid body. With power supplied to solenoid, ensure solenoid valve moves outward. With power disconnected, ensure solenoid valve moves inward. Replace solenoid if operating sound cannot be heard. If solenoid operates, diagnose valve body malfunction.

Hope this helps

Saturday, July 17th, 2010 AT 7:12 PM