Hello,

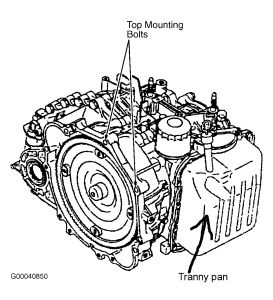

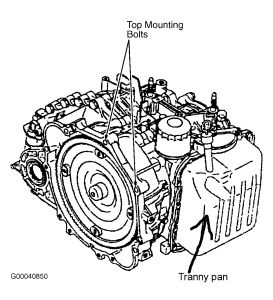

1.Remove drain plug from transaxle oil pan. Drain fluid. Remove oil pan bolts, and tap pan to break loose. Remove oil pan. Clean or replace oil filter/screen. Tighten filter bolts to specification.

TORQUE SPECIFICATIONS .

Oil Filter/Screen Bolt = 44 - 62 Foot Lbs

Oil Pan Bolts = 89 106 foot lbs

2.Clean gasket surfaces of transaxle case and oil pan. Install oil pan with NEW gasket, and tighten oil pan bolts to specification. Using NEW gasket, install and tighten drain plug to specification.

3.Pour 4.2 qts. (4.0L) of ATF into transaxle through dipstick tube. Unless torque converter was drained, dry-fill amount is not necessary. Start engine and allow to idle for at least 2 minutes. With parking brake applied, move gearshift lever slowly to each position and back to Neutral. Recheck fluid level on dipstick.

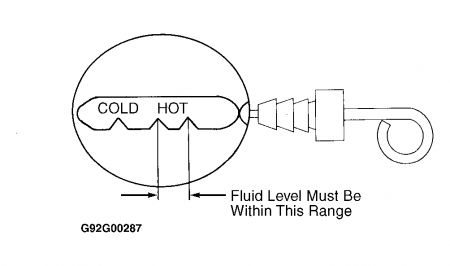

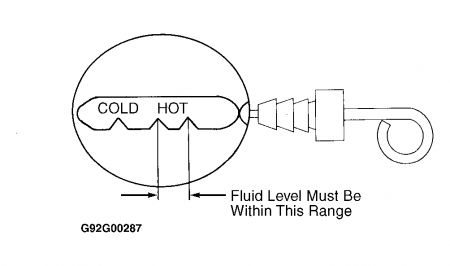

4.Add sufficient ATF to bring fluid level to lower mark. Recheck fluid level after transaxle is at normal operating temperature. Fluid level should be between marks of dipstick HOT range. See Fig. 2 . Insert dipstick fully into tube to prevent dirt from entering transaxle.

Fig 2.

.

SPONSORED LINKS

Saturday, September 25th, 2010 AT 3:10 PM