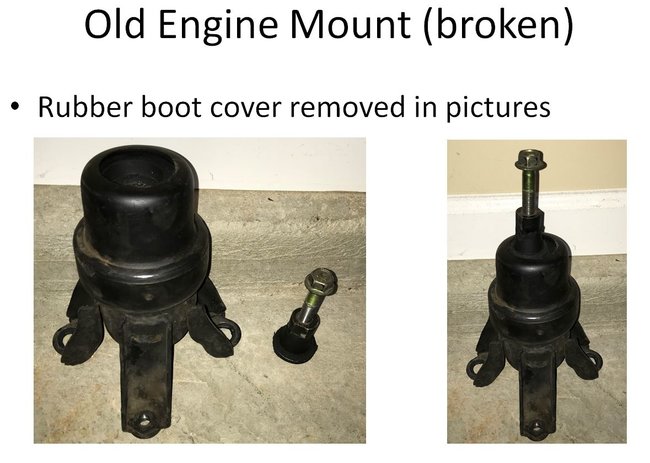

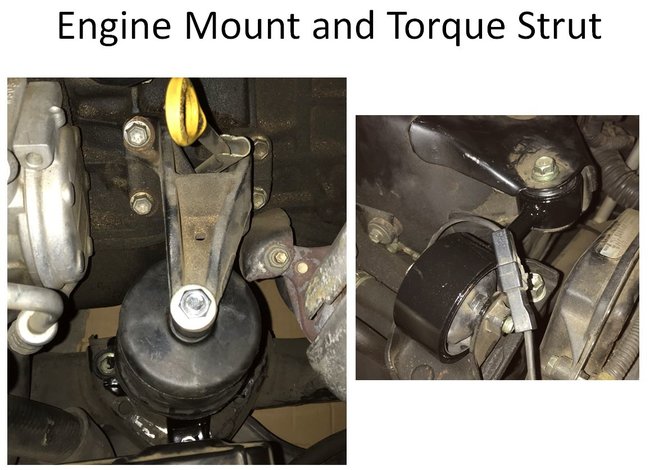

The Torque Strut Mount looks like it can be replaced without too much concern. The Motor Mount at the front of the engine is where I need help.

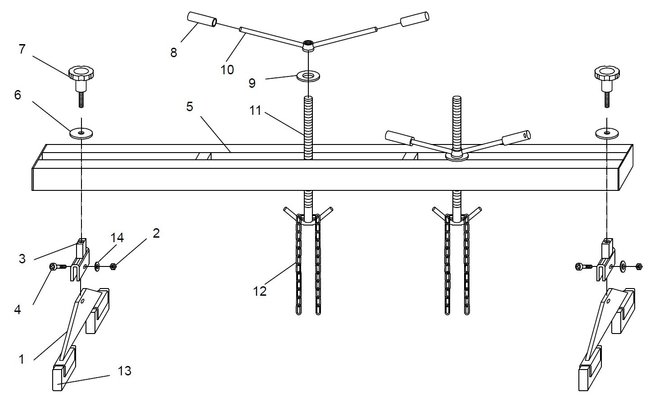

How do I support the weight of the engine to enable me to remove and replace the motor mount?

Also, the part currently installed appears to be aftermarket rather than OEM, and I plan to use the OEM part. The attachment shown in the picture indicates a bolt head at the top of the motor mount. The OEM part has threads and a nut. I hope the OEM part comes with the nut, or I will need to find one.

My key question is, how do I safely support the engine so that I can change the front engine mount?

Monday, September 3rd, 2018 AT 4:56 PM