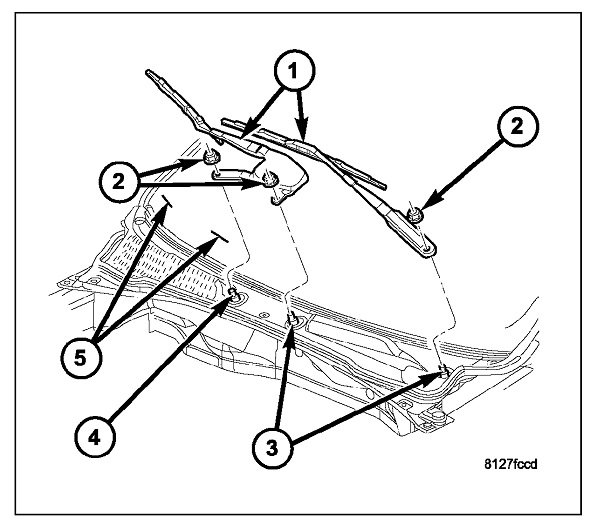

One problem that used to be very common was the nuts would work loose on the wiper arm pivots. That's item 2 in the first drawing. The splined shafts are tapered. A loose nut let the arm lift up a little, then slip on those splines. The fix was to set the arms in their proper orientation, then use a 15 mm wrench to tighten the nut. Typically they only needed about a quarter to half turn. Each nut only affected that one arm, so it was common to see just one arm moving normally and the other one was stuck in one spot, or was skipping and moving erratically.

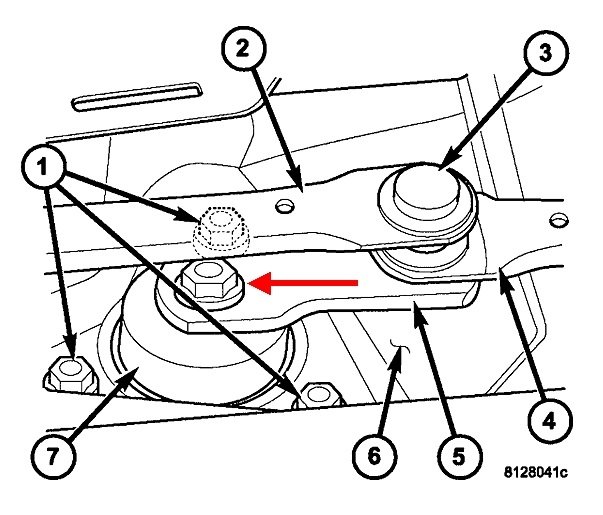

Since both arms are stuck at the same time and in the same orientation, and since you can hear the wiper motor running, a better suspect is the nut worked loose on the shaft of the motor, then the linkage became separated from the shaft. That's shown with the red arrow in the second drawing. The hole in the linkage looks like a rectangle, but to prevent installing that linkage 180 degrees backward, one of the shorter sides of that rectangle is rounded. The motor's shaft has a matching rounded side, so that link can only be reinstalled the right way.

Images (Click to make bigger)

Thursday, January 23rd, 2020 AT 4:46 PM