Okay, so we know the ABS is working correctly.

I can make a comment of value for the rears not locking up in reverse, but it only applies to drum brakes. Some lightweight cars use a "non-servo" rear drum brake in which both shoes are the same size. One applies going forward and the other applies in reverse. In the case of the older K-cars, when the front, or "leading" shoe wore out, you could switch them front-to-rear and get twice the life out of them.

All larger cars and trucks use a "duo-servo" rear drum brake. With those, the leading shoe, (toward the front of the vehicle), is smaller, and the trailing show is larger. The trailing shoe does the stopping. The leading shoe's job is to grab the spinning drum and try to rotate with it. As it does, it pushes on the star wheel adjuster assembly, and that pushes the bottom of the trailing shoe into the drum.

At the same time, the rear piston in the wheel cylinder pushes the top of the trailing shoe into the drum. So there's two forces acting on the trailing shoe. It does all the work when going forward, so it has to be bigger to last as long as the smaller leading shoe.

When you back up, the roles are reversed. The larger trailing shoe acts on the bottom of the smaller leading shoe. This time the front piston in the wheel cylinder pushes the top of the leading shoe into the drum. Since that shoe is so much smaller, it is much less-effective at stopping that wheel when backing up.

To add to the misery, when stopping when backing up, more vehicle weight is transferred to the rear, so the tires grip the road harder. That makes lock-up even less likely.

In addition, drum shoes are self-energizing, meaning once they contact the rotating drum, they tend to get pulled into it and grab harder on their own. Disc brakes don't have any of those benefits. They aren't self-energizing, so all their stopping power has to come from your foot on the brake pedal. This is why 99 percent of vehicles with disc brakes have a power brake booster.

Another test that I thought I mentioned already but looks like not here, is to stop on a slight incline, shift to "neutral", release the brakes, then see if the truck creeps downhill on its own. If it does not, suspect the front calipers are not fully releasing. On some models such as my older Caravans, that is real commonly caused by the metal bracket crimped around the middle of the front rubber flex hoses. Rust builds up inside the crimps and constricts the hose. You can easily force brake fluid under pressure through the restriction to apply the brakes, but then the fluid can't return on its own. The brake pedal will be too high and too hard, and the brakes will grab easily. Your hoses don't have that metal bracket, but we still run into a fair number of flex hoses that tear inside and form a restriction. This can happen faster if a caliper is allowed to hang by the hose during routine brake service.

If you find a brake isn't releasing, place a block about a foot downhill of a tire so you don't look funny chasing after the truck, then crawl underneath and open the bleeder screws. If that allows the brake to release, pressurized brake fluid is being trapped somewhere and is unable to return back to the reservoir. We figure out where that restriction is by opening the hydraulic system at various places.

The worst case is if a brake releases when you loosen the steel lines right at the master cylinder. That is caused by brake fluid contaminated with a petroleum product such as engine oil, transmission fluid, power steering fluid, axle grease, or penetrating oil. That contamination causes rubber parts to swell. A clue is the rubber bladder seal under the reservoir's cap will be blown up and mushy, and you won't be able to pop it back in place. In the master cylinder, the rubber lip seals grow past the fluid return ports and blocks them. Another clue is since the brakes are dragging, they get hot, and that heat migrates into the brake fluid causing it to expand. Since it can't get back to the reservoir, it applies the calipers harder and harder.

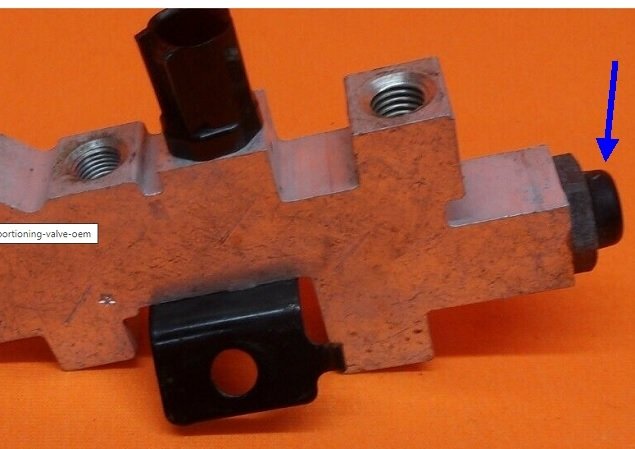

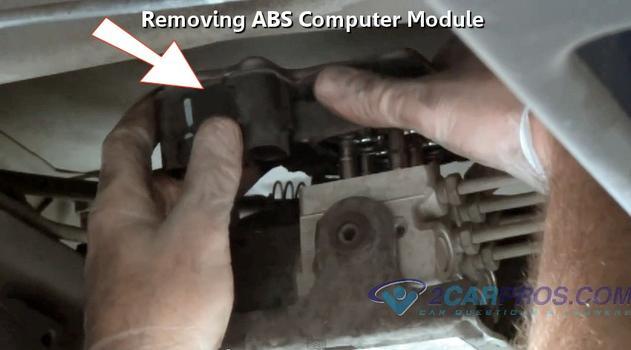

I don't think you're going to run into this contamination, but if you do, the only proper repair is to remove every part in the hydraulic system that contains rubber parts that contact the brake fluid, flush and dry the steel lines, then install all new rubber parts. That includes the master cylinder, calipers, rubber flex hoses, combination valve assembly, ABS valve assembly, and when used, wheel cylinders, ABS controller, and rear height-sensing proportioning valve. If any rubber part is not replaced, the contamination will leach out of it and recontaminate the new brake fluid.

The only exception to this is if a contaminating fluid is poured into the reservoir and the mistake is caught right away. In that case I would suck out as much fluid as possible with a turkey baster, then remove the steel lines at the master cylinder and run a full small can of clean fresh brake fluid through it. Every year I did a demonstration for my students on the effects of this contamination. With two inches of brake fluid in a small beaker, I added a wheel cylinder lip seal and one drop of oil or power steering fluid. It took a week, then we found the contaminated seal was slimy, mushy, and it had grown by about 20 percent. The key is it took a week.

After doing some research, it seems a lot of people have the same complaints of easy front brake lock-up. Quite a few conclude it's due to rust build-up on the rotors overnight and the problem only occurs once in the morning, as I described with my Volare. No one can really point to a definite defect.

What I find interesting is no one complained of this when the trucks were new. All manufacturers spend a real lot of time and resources developing brake systems that are carefully balanced front-to-rear. That involves piston diameters in the calipers, wheel cylinders, and master cylinder, drum diameter and width, square inches of pad contact, and valving. The main point of importance is when any aftermarket brake parts manufacturer offers replacement parts, they have to maintain that brake balance. It doesn't matter if they use different friction material, the combination of "coefficient of friction, and physical size have to equal what was originally designed for the vehicle. Cheaper linings might have less resistance to heat-related brake fade, for example, but under normal conditions they will perform just as well as more expensive linings.

Given that wondrous information, I wouldn't expect to find the wrong brake pads, but what about the calipers? In the '90s there were four different caliper designs that could be bolted onto one corner of the truck. Two had an 80mm piston and two had an 88mm piston. (The other variable was low drag for better fuel mileage, or normal calipers). If you were given the wrong ones at an auto parts store, those with the larger pistons would bolt right on, but require the brake pedal to move a little more than normal, and the caliper would apply significantly more pressure to the pads. The different piston sizes were meant for different versions of options on the truck, and they weren't meant to be changed to a different size.

There's one more thing I can share, but I'm a little hesitant to suggest this. There was a service bulletin related to early front pad wear on the larger trucks that were constantly heavily-loaded. We had quite a few in my city that had huge boxes with all kinds of tools for plumbing or heavy equipment. A half dozen in particular were for a company that installed and serviced hoists, and they were grossly overloaded all the time. To alleviate the fast front pad wear, the service bulletin instructed us to increase the diameter of the rear drum wheel cylinders. For these grossly-overloaded trucks, we could go up two sizes larger, but that wheel cylinder wasn't available through Chrysler. They had to come from a GM dealer. In every case it was an effective solution to the rapid pad wear on front, but that is not something we would alter for the typical daily commuter. These work trucks were so heavily-loaded, that locking brakes was the furthest thing on their minds. The modification made the rear brakes work harder, thus taking some of the load off the front pads.

I'll keep researching this to try to find you a better answer.

Tuesday, December 29th, 2020 AT 4:39 PM