Wheel Bearing and Hub

Removal and Installation

CAUTION: Suspension fasteners are critical parts because they affect performance of vital components and systems and their failure can result in major service expense. A new part with the same part number must be installed if installation is necessary. Do not use a new part of lesser quality or substitute design. Torque values must be used as specified during reassembly to make sure of correct retention of these parts.

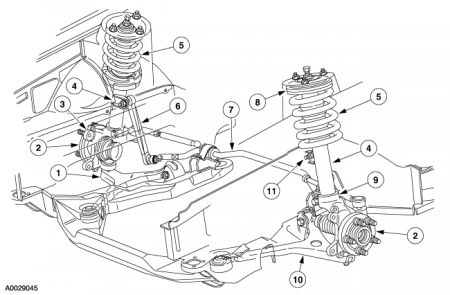

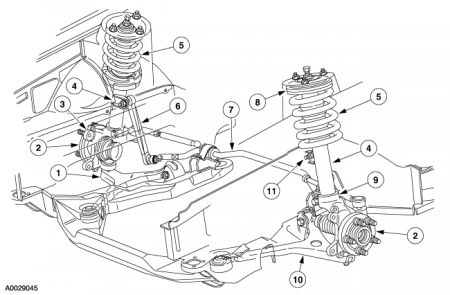

Remove the wheel knuckle (3K185). .

CAUTION: The wheel bearing and hub is not pressed into the knuckle. Do not use a slide hammer or strike the inner race of the bearing. Damage to the bearing can result.

NOTE: If necessary, lubricate the knuckle and bearing with Rust Penetrant and Inhibitor F2AZ-19A501-A or equivalent meeting Ford specification ESR-M99C56-A.

Remove the bolts and the wheel hub and bearing (1104). Discard the bolts.

CAUTION: The knuckle bore must be clean enough to allow the wheel bearing and hub to seat completely by hand. Do not press or draw the wheel hub and bearing into place.

Clean and inspect the knuckle bearing bore. If the knuckle is cracked, install a new knuckle.

Lubricate the knuckle bearing bore with Motorcraft High Temperature Nickel Anti-Seize Lubricant F6AZ-9L494-AA or equivalent meeting Ford specification ESE-M12A4-A.

To install, reverse the removal procedure.

SPONSORED LINKS

Sunday, October 3rd, 2010 AT 7:08 AM