A bad ignition switch or shorted wire will do it...Test pump withthe self test connector, gound fuel pump test lead, turn the key on, does pump run?

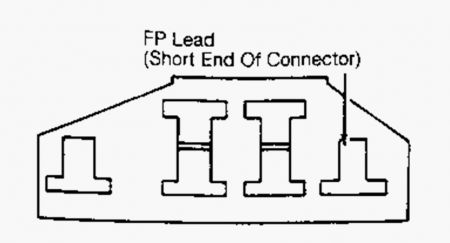

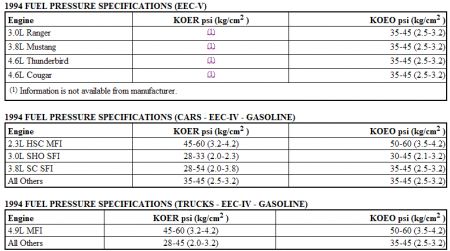

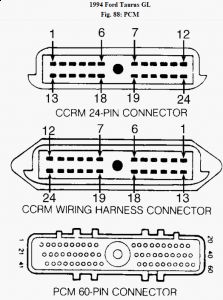

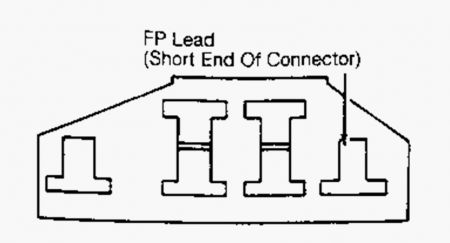

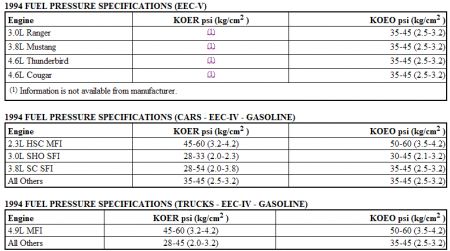

FUEL DELIVERY Fuel Pump Relay See RELAYS under MODULES, RELAYS & SOLENOIDS. Constant Control Relay Module (CCRM) See CIRCUIT TEST X in TESTS W/CODES - EEC-IV (3.0L) article in the ENGINE PERFORMANCE section. Variable Control Relay Module (VCRM) See CIRCUIT TEST XB in TESTS W/CODES - EEC-IV (3.0L) article in the ENGINE PERFORMANCE section. 1. System Integrity Check On Taurus 3.0L Flex Fuel with a Code 141 present, visually inspect fuel delivery system for leaks and damaged lines. Repair as necessary. Perform QUICK TEST to verify pass code. Proceed to TESTS W/CODES - EEC-IV (3.0L) article in the ENGINE PERFORMANCE section. Service any fuel related codes prior to continuing with this test. On all models, perform the following checks: Ã Â Â Ensure Inertia Fuel Shutoff (IFS) switch reset button is not in upper (tripped) position. See INERTIA FUEL SHUTOFF (IFS) SWITCH LOCATION table. Ã Â Â Ensure battery is fully charged and fuel related fuses are okay. Ã Â Â Check fuel tank contents and fuel gauge accuracy. If any fault is detected, repair as necessary. If system checks are okay, go to next step. 2. Check Fuel Pressure Release fuel pressure. See FUEL SYSTEM PRESSURE RELEASE. Install fuel pressure gauge. Connect a jumper wire between ground and fuel pump test terminal at Data Link Connector (DLC). See Fig. 3 .Turn ignition on to activate pump. Check and record fuel pressure. For fuel pressure specifications, see FUEL PRESSURE SPECIFICATIONS article. Proceed to appropriate step as indicated: Ã Â Â If fuel pressure is within specification, go to next step. Ã Â Â If fuel pressure is low, go to step 10). Ã Â Â If fuel pressure is high, go to step 11). Fig. 3: Data Link Connector Terminal ID 3. Check For Fuel Pressure Leak-Down Operate fuel pump as in step 2) for a minimum of 30 seconds. Turn ignition off and disconnect jumper wire from DLC. Wait one minute then check fuel pressure gauge. If fuel pressure remains within 5 psi of specification, go to step 5). If fuel CAUTION: Inspect fuel system for leaks and damage before testing fuel pump.pressure does not remain within 5 psi of specification, go to next step. 4. Check Fuel Pressure Regulator Diaphragm Turn ignition off. Ensure vacuum hose is connected to fuel pressure regulator. Start and run engine for 10 seconds. Stop engine, and wait 10 seconds. Start and run engine for 10 seconds. Stop engine. Remove vacuum hose from pressure regulator. If fuel is present in vacuum port, replace fuel pressure regulator and repeat step 2). If fuel is not present, either fuel injectors are leaking down or check valve in fuel pump is defective. Repair as necessary and repeat step 2). 5. Check Fuel Pressure With Engine Load Ensure vacuum hose is still disconnected from pressure regulator. Observe pressure gauge while driving vehicle with heavy accelerations. If fuel pressure remains within 3 psi during test, reconnect vacuum hose to pressure regulator and go to next step. If fuel pressure does not remain within 3 psi, go to step 8). 6. Check Fuel Pressure Regulator Install vacuum gauge to intake manifold. Start engine. Observe vacuum and fuel pressure gauge while accelerating and decelerating engine. When engine is accelerating, vacuum reading should decrease and fuel system pressure should increase. When engine is decelerating, vacuum reading should increase and fuel system pressure should decrease. If readings are as specified, fuel system is okay and test is compete. If gauge readings are not as specified, go to next step. 7. Check Vacuum Supply Disconnect and plug fuel pressure regulator hose. Attach vacuum pump to fuel pressure regulator. Start engine. Apply vacuum to pressure regulator while observing fuel pressure gauge. If fuel pressure changes as vacuum changes, repair restriction in vacuum supply hose. If fuel pressure does not change as vacuum changes, replace fuel pressure regulator. 8. Check Fuel Filter Check for plugged fuel filter. Replace filter as necessary, and repeat step 2). If filter is okay, go to next step (Taurus Flex Fuel) or replace fuel pump (all other models). 9. Check Voltage At Both Pump Speeds Turn ignition off. Connect DVOM between ground and either terminal at Inertia Fuel Shutoff (IFS) switch. IFS switch is located in left side of trunk. Start engine. Voltage reading should be about 9 volts at idle and 13 volts at 3500 RPM. If voltage is as specified, check for faulty fuel pump ground connection. Repair as necessary. If ground is okay, replace fuel pump. On Taurus Flex Fuel, check Constant Control Relay Module (CCRM). See CIRCUIT TEST X in appropriate TESTS W/CODES - EEC-IV (3.0L) article in the ENGINE PERFORMANCE section. 10. Check For Low Pressure Causes Turn ignition off. Release fuel system pressure. See FUEL SYSTEM PRESSURE RELEASE. Disconnect fuel return hose from pressure regulator. Using a separate piece of fuel hose, connect one end of hose to fuel return port at pressure regulator and place other end of hose into a suitable container. With jumper wire still connected to DLC as in step 2), turn ignition on (engine off). If fuel pressure is still low and fuel is being returned into container, replace pressure regulator. If fuel pressure is still low and fuel is not being returned into container, replace fuel pump and repeat step 2). 11. Check For High Pressure Causes Turn ignition off. Release fuel system pressure. See FUEL SYSTEM PRESSURE RELEASE. Disconnect fuel return hose from pressure regulator. Using a separate piece of fuel hose, connect one end of hose to fuel return port at pressure regulator and place other end of hose into a suitable container. With jumper wire still connected to DLC as in step 2), turn ignition on (engine off). If fuel pressure is within specification, replace pressure regulator and repeat step 2). For fuel pressure specifications, see FUEL PRESSURE SPECIFICATIONS article. If fuel pressure is not within specification, go to next step. 12. Check Fuel Return System Turn ignition off. Fuel return hose should still be disconnected at pressure regulator. Disconnect fuel return hose near fuel tank. Apply 3-5 psi of regulated air to return line port at pressure regulator. If air flows freely through return line, replace fuel pump and repeat step 2). If air does not flow freely, check fuel return system for restrictions. Repair asnecessary and repeat step 2).

SPONSORED LINKS

Friday, April 3rd, 2009 AT 2:13 PM