Time to run some circuit tests.

SYSTEM/COMPONENT TESTS - EEC-V -1996 Ford Mustang GT

Page 1 of 15

ARTICLE BEGINNING

INTRODUCTION

Before testing separate components or systems, perform basic diagnostic procedures in appropriate F - BASIC TESTING article. Since many computer-controlled and monitored components set a Diagnostic Trouble Code (DTC) if they malfunction, also perform self-diagnostics in appropriate G - TEST W/CODES article.

NOTE: Testing individual components does not isolate short or open circuits. Perform all voltage tests with a Digital Volt-Ohmmeter (DVOM) with a minimum 10-megohm input impedance, unless stated otherwise in test procedure. Use DVOM to isolate shorted or open wiring harness.

NOTE: For identification of circuits and terminals referenced in test procedures, see appropriate WIRING DIAGRAMS article.

COMPUTERIZED ENGINE CONTROLS

POWERTRAIN CONTROL MODULE

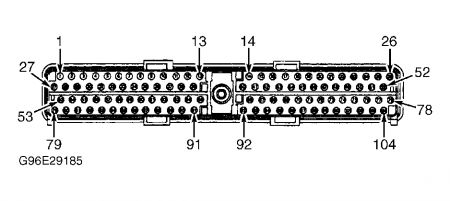

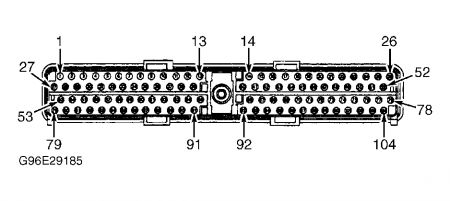

Ground Circuits

1.Using a DVOM, check for continuity to ground at the following Powertrain Control Module (PCM) connector terminals. See IDENTIFYING POWERTRAIN CONTROL MODULE PWR GND TERMINALS table. See Fig. 1 . If continuity does not exist, repair open ground circuit as necessary. If continuity exists, go to next step.

IDENTIFYING POWERTRAIN CONTROL MODULE PWR GND TERMINALS Application PCM Harness Connector Terminal No. All Others 24, 51, 76, 77 & 103 Contour & Mystique, & Escort & Tracer (1.9L) 24, 51, 77 & 103

2.Touch negative lead of DVOM to a good ground. With vehicle running, backprobe positive lead of DVOM to each ground terminal. DVOM should indicate less than one volt. If reading is greater than one volt, check for open, corrosion or loose connection on ground lead.

Power Circuits

Turn ignition off. Using a DVOM, check for battery voltage between ground and PCM terminal No. 55 (KAPWR). Turn ignition switch to START or RUN position. Check for battery voltage between ground and PCM connector terminals No. 71 and 97 (VPWR). If battery voltage is not present, power is not being supplied from EEC power relay. See CIRCUIT TEST B under CIRCUIT TESTS

10/4/2008

SYSTEM/COMPONENT TESTS - EEC-V -1996 Ford Mustang GT

Page 2 of 15

in appropriate G - TEST W/CODES article.

POWERTRAIN CONTROL MODULE LOCATION

Application Aerostar, Crown Victoria, Bronco, Econoline, Grand Marquis, Pickup & Town Car Continental Rear Center Of Engine Compartment Under Splash Cover Contour & Mystique Right Rear Corner Of Engine Compartment, Behind Power Steering Reservoir Cougar, Mustang & Thunderbird In Passenger Compartment, Behind Right Kick Panel Escort & Tracer In Passenger Compartment, Below Center Of Instrument Panel Explorer, Mountaineer, Ranger, Sable, Taurus & Windstar Mark VIII In Passenger Compartment, On Left Side Cowl Behind Instrument Panel Location Left Rear Corner Of Engine Compartment, Near Brake Booster In Engine Compartment, Right Rear Side On Cowl

Fig. 1: Identifying Powertrain Control Module 104-Pin Connector Terminals

ENGINE SENSORS & SWITCHES

NOTE: Component tests are included when provided by manufacturer. If component tests are not provided, see appropriate test in G - TEST W/CODES article when stated. For additional sensor specifications, see appropriate K - SENSOR RANGE CHARTS article.

AIR CONDITIONING PRESSURE SWITCH

10/4/2008

SYSTEM/COMPONENT TESTS - EEC-V -1996 Ford Mustang GT

Page 3 of 15

For Air Conditioning Pressure (ACP) switch testing procedure and specifications, see CIRCUIT TEST DS under CIRCUIT TESTS in appropriate G - TEST W/CODES article.

BRAKE ON/OFF SWITCH

For Brake On/Off (BOO) switch testing procedure and specifications, see CIRCUIT TEST FD under CIRCUIT TESTS in appropriate G - TEST W/CODES article.

CAMSHAFT POSITION SENSOR (4.0L & 5.0L)

For Camshaft Positon Sensor testing procedure, see CIRCUIT TEST DR - CYLINDER IDENTIFICATION for 4.0L engine, or CIRCUIT TEST DR - CYLINDER IDENTIFICATION

for 5.0L engine.

CLUTCH PEDAL POSITION SWITCH

For Clutch Pedal Position (CPP) switch testing procedure and specifications, see CIRCUIT TEST TA under CIRCUIT TESTS in appropriate G - TEST W/CODES article.

ENGINE COOLANT TEMPERATURE SENSOR

Tips � � � � Click a link to view tip

Tech1 coolant temperature sensor

Engine Coolant Temperature (ECT) sensor uses a 5-volt reference voltage during engine operation. To check ECT signal voltage, backprobe between signal terminal and ground with engine running. To check sensor resistance, disconnect sensor and measure resistance between sensor terminals. For specifications, see ENGINE COOLANT TEMPERATURE SENSOR SPECIFICATIONS table. For additional testing information, see CIRCUIT TEST DA under CIRCUIT TESTS in appropriate G - TEST W/CODES article.

ENGINE COOLANT TEMPERATURE SENSOR SPECIFICATIONS (1) Temperature °F ( °C) (2) Volts (3) Ohms 50 (10) 3.51 58,750 68 (20) 3.07 37,300 86 (30) 2.60 24,270 104 (40) 2.13 16,150 122 (50) 1.70 10,970 140 (60) 1.33 7700 158 (70) 1.02 5370 176 (80) 0.78 3840 194 (90) 0.60 2800

10/4/2008

SYSTEM/COMPONENT TESTS - EEC-V -1996 Ford Mustang GT

Page 4 of 15

212 (100) 230 (110) 248 (120)

0.46 0.35 0.27

2070 1550 1180

(1) Values may differ by as much as 15 percent.

(2) Backprobe between signal terminal and ground with engine running.

(3) Measure resistance between sensor terminals.

HEATED OXYGEN SENSOR

1.Faults in Heated Oxygen Sensor (HO2S) or circuit should set a Diagnostic Trouble Code (DTC). Perform QUICK TEST in appropriate G - TESTS W/CODES article. If no DTC has been set, check HO2S HTR resistance. Using a DVOM, measure resistance between HO2S HTR GND and VPWR terminals. See appropriate WIRING DIAGRAMS article. If resistance is 3-30 ohms, HO2S HTR circuit is okay, go to next step. If resistance is not 3-30 ohms, replace HO2S sensor. 2.With ignition off. Measure resistance between HO2S HTR GND terminal and HO2S case. Measure resistance between HO2S HTR GND and SIG RTN terminals. Measure resistance between HO2S VPWR terminal and HO2S case. If each resistance measurement is more than 10 k/ohms, HO2S is okay. If any resistance is 10 k/ohms or less, replace HO2S. For additional testing information, see CIRCUIT TEST H under CIRCUIT TESTS in appropriate G - TEST W/CODES article.

INERTIA FUEL SHUTOFF SWITCH

Ensure ignition is off. Locate Inertia Fuel Shutoff (IFS) switch. See INERTIA FUEL SHUTOFF SWITCH LOCATIONS table. Shake or lightly tap on IFS switch to cause switch to open and reset button should pop up. Fuel pump should not operate and car should stall. Push down on reset button. Fuel pump should operate.

INERTIA FUEL SHUTOFF SWITCH LOCATIONS Application Location Aerostar, Bronco, Econoline, Pickup & Ranger Behind Right Kick Panel Continental, Crown Victoria & Grand Marquis, Mark VIII & Town Car Contour & Mystique Behind Left Kick Panel Escort & Tracer Right Side Of Trunk Or Cargo Area, Above Wheel Well Explorer & Mountaineer Behind Instrument Panel, Below Radio Mustang Lower Left Rear Corner Of Trunk Sable & Taurus Sedan Right Side Of Trunk Behind Wheel Well Wagon Behind Right Rear Panel In Cargo Area Windstar Behind Right Rear Panel In Cargo Area On Left Side Of Trunk, Behind Trim Panel

10/4/2008

SYSTEM/COMPONENT TESTS - EEC-V -1996 Ford Mustang GT

Page 5 of 15

INTAKE AIR TEMPERATURE SENSOR

Intake Air Temperature (IAT) sensor uses a 5-volt reference voltage during engine operation. To check IAT signal voltage, backprobe between signal terminal and ground with engine running. To check sensor resistance, disconnect sensor and measure resistance between sensor terminals. For specifications, see INTAKE AIR TEMPERATURE SENSOR SPECIFICATIONS table. For additional testing information, see CIRCUIT TEST DA under CIRCUIT TESTS in appropriate G - TESTS W/CODES article.

INTAKE AIR TEMPERATURE SENSOR SPECIFICATIONS (1) Temperature °F ( °C) (2) Volts (3) Ohms 50 (10) 3.51 58,750 68 (20) 3.07 37,300 86 (30) 2.60 24,270 104 (40) 2.13 16,150 122 (50) 1.70 10,970 140 (60) 1.33 7700 158 (70) 1.02 5370 176 (80) 0.78 3840 194 (90) 0.60 2800 212 (100) 0.46 2070 230 (110) 0.35 1550 248 (120) 0.27 1180

(1) Values may differ by as much as 15 percent.

(2) Backprobe between signal terminal and ground with engine running.

(3) Measure resistance between sensor terminals.

KNOCK SENSOR

Faults in Knock Sensor (KS) or circuit should set a Diagnostic Trouble Code (DTC). See QUICK TEST in appropriate G - TESTS W/CODES article. If no DTC has been set, go to CIRCUIT TEST DG under CIRCUIT TESTS in appropriate G - TESTS W/CODES article for KS and circuit testing.

MASS AIRFLOW SENSOR

Faults in Mass Airflow (MAF) sensor or circuit should set a Diagnostic Trouble Code (DTC). See QUICK TEST in appropriate G - TESTS W/CODES article. If no DTC has been set, go to CIRCUIT TEST DC under CIRCUIT TESTS in appropriate G - TESTS W/CODES article for MAF sensor and circuit testing.

PARK/NEUTRAL POSITION SWITCH

For Park/Neutral Position (PNP) switch test procedures, see CIRCUIT TEST TA under CIRCUIT

10/4/2008

SYSTEM/COMPONENT TESTS - EEC-V -1996 Ford Mustang GT

Page 6 of 15

TESTS in appropriate G - TEST W/CODES article.

POWER STEERING PRESSURE SWITCH

For Power Steering Pressure (PSP) switch test procedures, see CIRCUIT TEST FF under CIRCUIT TESTS in appropriate G - TEST W/CODES article.

THROTTLE POSITION SENSOR

Ensure none of following conditions exist:

� � � Binding throttle linkage.

� � � TP sensor loose or not seated properly.

� � � Throttle plate not fully closed.

Faults in TP sensor or circuit should set a Diagnostic Trouble Code (DTC). See QUICK TEST in appropriate G - TESTS W/CODES article. If no DTC has been set, see CIRCUIT TEST DH under CIRCUIT TESTS in appropriate G - TESTS W/CODES article for additional sensor and circuit testing.

TRANSMISSION RANGE SENSOR

For Transmission Range (TR) sensor test procedures, see CIRCUIT TEST TD under CIRCUIT TESTS in appropriate G - TEST W/CODES article.

VEHICLE SPEED SENSOR

Faults in Vehicle Speed Sensor (VSS) or circuit should set a Diagnostic Trouble Code (DTC). See QUICK TEST in appropriate G - TESTS W/CODES article. If no DTC has been set, go to CIRCUIT TEST DP under CIRCUIT TESTS in appropriate G - TESTS W/CODES article for VSS and circuit testing.

MODULES, MOTORS, RELAYS & SOLENOIDS

CANISTER PURGE SOLENOID

For diagnostic procedures for Canister Purge (CANP) solenoid, see CANISTER PURGE SOLENOID under FUEL EVAPORATION under EMISSION SYSTEMS & SUB-SYSTEMS.

CANISTER VENT SOLENOID

For diagnostic procedures for Canister Vent (CV) solenoid, see CANISTER VENT SOLENOID under FUEL EVAPORATION under EMISSION SYSTEMS & SUB-SYSTEMS.

10/4/2008

SYSTEM/COMPONENT TESTS - EEC-V -1996 Ford Mustang GT

Page 7 of 15

EGR VACUUM REGULATOR SOLENOID

For diagnostic procedures for EGR Vacuum Regulator (EVR) solenoid, see EGR VACUUM REGULATOR SOLENOID under EXHAUST GAS RECIRCULATION under EMISSION

SYSTEMS & SUB-SYSTEMS.

EVAP CANISTER

For diagnostic procedures for EVAP canister, see EVAP CANISTER under FUEL EVAPORATION under EMISSION SYSTEMS & SUB-SYSTEMS.

FUEL PUMP RELAY

NOTE: To identify fuel pump relay terminals, refer to numbers molded on relay. Two different numbered relays are used. Fuel pump relay terminals may be numbered 1-5 or terminals may be numbered 30, 85, 86, 87 and 87A. On relays that are numbered 1-5; terminals for relay coil are terminals No. 1 and 2. On relays that are numbered 30, 85, 86, 87 and 87A; terminals for relay coil are terminals No. 85 and 86.

1.Turn ignition off. On fuel pump relays that terminals are numbered 1-5, measure resistance between relay terminal No. 1 and all other relay terminals. Resistance should be 40-120 ohms between terminals No. 1 and 2 and more than 10 k/ohms between terminal No. 1 and other relay terminals. 2.On fuel pump relays that terminals are numbered 30, 85, 86, 87 and 87A, measure resistance between relay terminal No. 85 and all other relay terminals. Resistance should be 40-120 ohms between terminals No. 85 and 86 and more than 10 k/ohms between terminal No. 85 and other relay terminals. On both relays, if resistance is not as specified replace relay. If resistance is okay, see TEST KA under CIRCUIT TESTS in appropriate G - TESTS W/CODES article for additional fuel pump circuit testing procedures.

FUEL TANK PRESSURE SENSOR

For Fuel Tank Pressure (FTP) sensor test procedures, see CIRCUIT TEST HX under CIRCUIT TESTS in appropriate G - TEST W/CODES article.

IDLE AIR CONTROL SOLENOID

1.Idle Air Control (IAC) Solenoid is a by-pass air type. Ensure ignition is off. Disconnect IAC solenoid harness connector. Measure resistance between IAC solenoid connector terminals. Solenoid has an internal diode. Connect positive lead from DVOM to VPWR terminal and negative lead to IAC terminal. Resistance should be 6-13 ohms. If resistance is not 6-13 ohms, replace solenoid. If resistance is 6-13 ohms, go to next step. 2.Measure resistance between either IAC solenoid terminal and IAC solenoid case. If resistance is 10 k/ohms or less, replace IAC solenoid. If resistance is more than 10 k/ohms, IAC solenoid may be okay. See CIRCUIT TEST KE under CIRCUIT TESTS in appropriate G - TESTS

10/4/2008

SYSTEM/COMPONENT TESTS - EEC-V -1996 Ford Mustang GT

Page 8 of 15

W/CODES article for additional testing and specifications.

PURGE FLOW SENSOR

For diagnostic procedures for Purge Flow (PF) sensor, see PURGE FLOW SENSOR under FUEL EVAPORATION under EMISSION SYSTEMS & SUB-SYSTEMS.

VAPOR MANAGEMENT VALVE

For diagnostic procedures for Vapor Management Valve (VMV), see VAPOR MANAGEMENT VALVE under FUEL EVAPORATION under EMISSION SYSTEMS & SUB-SYSTEMS.

FUEL SYSTEM

FUEL SYSTEM PRESSURE RELEASE

With Fuel Pressure Gauge

WARNING: Always relieve fuel pressure before disconnecting any fuel injection-related component. DO NOT allow fuel to contact engine or electrical components.

1.Remove fuel cap to release fuel tank pressure. Remove relief valve cap. Relief valve is located on fuel supply manifold. Using Fuel Pressure Gauge (T80L-9974-B), release fuel pressure from relief valve (Schrader valve). 2.If fuel pressure gauge is not available, disconnect electrical connector to IFS switch. For IFS switch location, see INERTIA FUEL SHUTOFF SWITCH LOCATIONS table. Crank engine for 15 seconds to reduce system pressure. Turn ignition off. Reconnect IFS switch connector.

Without Fuel Pressure Gauge

If fuel pressure gauge is not available, disconnect Inertia Fuel Shutoff (IFS) switch. For IFS location, see INERTIA FUEL SHUTOFF SWITCH LOCATIONS table under ENGINE SENSORS & SWITCHES. Remove fuel cap to release fuel tank pressure. Crank engine for 15 seconds to release system pressure.

FUEL DELIVERY

NOTE: For 1995 fuel pressure specifications, see FUEL PRESSURE SPECIFICATIONS article. For 1996 fuel pressure specifications, see FUEL PRESSURE SPECIFICATIONS article.

Fuel Pump Relay

10/4/2008

SYSTEM/COMPONENT TESTS - EEC-V -1996 Ford Mustang GT

Page 9 of 15

See FUEL PUMP RELAY under MODULES, MOTORS, RELAYS & SOLENOIDS.

CAUTION:Inspect fuel system for leaks and damage before testing fuel pump.

1) System Integrity Check

Perform the following checks:

� � � Visually inspect fuel system (fuel lines, filter, pump, injectors, pressure regulator, etc.).

� � � Ensure Inertia Fuel Shutoff (IFS) switch reset button is not in upper (tripped) position.

� � � Ensure battery is fully charged and fuel-related fuses are okay.

� � � Check fuel tank contents and fuel gauge accuracy. On vehicles with 2 fuel tanks, check both tanks. If any fault is detected, repair as necessary. If system checks are okay, go to next step.

2) Check Fuel Pressure

Install fuel pressure gauge. Check and record fuel pressure. For 1995 fuel pressure specifications, see FUEL PRESSURE SPECIFICATIONS article. For 1996 fuel pressure specifications, see FUEL PRESSURE SPECIFICATIONS article. If fuel pressure is as specified, testing is complete. If fuel pressure is not as specified, proceed as follows:

� � � For Natural Gas Vehicles

Go to CIRCUIT TEST HB, step 1) under CIRCUIT TESTS in appropriate G - TEST W/CODES article.

� � � For Models Except Natural Gas Vehicles

Go to CIRCUIT TEST HC, step 1) under CIRCUIT TESTS in appropriate G - TEST W/CODES article.

FUEL PRESSURE REGULATOR

See CIRCUIT TEST HC under CIRCUIT TESTS in appropriate G - TEST W/CODES article.

FUEL CONTROL

Fuel Injector Resistance

Disconnect injector harness connectors. Using DVOM, measure resistance between injector terminals. See FUEL INJECTOR RESISTANCE table. Replace any injector not within specification.

Fuel Injector Check

10/4/2008

SYSTEM/COMPONENT TESTS - EEC-V -1996 Ford Mustang GT

Page 10 of 15

Start engine and allow to idle. If engine will not start, crank engine for 10 seconds. Using a stethoscope, listen for clicking sound at each injector. If clicking sound is heard, fuel injector is operating. If clicking sound is not heard, go to CIRCUIT TEST HD, step 8) under CIRCUIT TESTS in appropriate G - TEST W/CODES article.

FUEL INJECTOR RESISTANCE (1)

Application Gasoline Models Natural Gas Models

Ohms 11-18 4-6

(1) Resistance values are for a single injector.

IDLE CONTROL SYSTEM

IDLE AIR CONTROL SOLENOID

Turn ignition off. Disconnect Idle Air Control I(AC) solenoid wiring harness connector. Connect DVOM positive lead to VPWR terminal of IAC solenoid wiring harness connector. See appropriate WIRING DIAGRAMS article. Connect DVOM negative lead to IAC terminal. If resistance is 6-13 ohms, go to next step. If resistance is not 6-13 ohms, replace IAC valve assembly.

IGNITION SYSTEM

NOTE: 1996 Taurus SHO 3.4L models use Coil On Plug (COP). COP faults should set a Diagnostic Trouble Code (DTC). For additional COP testing, see CIRCUIT TEST JF under CIRCUIT TESTS in appropriate G - TEST W/CODES article. For additional information and descriptions, see IGNITION SYSTEMS in appropriate E - THEORY & OPERATION article.

SYSTEM CHECKS

Preliminary Check

Perform following preliminary checks:

� � � Visually inspect engine compartment to verify vacuum hoses and spark plug wires are properly routed and securely connected.

� � � Examine all wiring harnesses and connectors for damage.

� � � Ensure all ground connections are clean and tight.

� � � Ensure battery is fully charged.

� � � All accessories should be off during diagnosis.

Test Equipment

10/4/2008

SYSTEM/COMPONENT TESTS - EEC-V -1996 Ford Mustang GT

Page 11 of 15

Following test equipment should be used:

� � � Spark Tester (D81P-6666-A Or D89P-6666-A)

� � � Digital Volt-Ohmmeter (DVOM)

� � � 12-Volt Test Light

� � � Remote Starter Switch

� � � Hand Held Scan Tool

� � � EEC-V Breakout Box (014-00950)

Diagnostic Aids

Test procedures are intended to identify faulty components or wiring while fault is present. If complaint is an intermittent condition, refer to H - TESTS W/O CODES article or perform CIRCUIT TEST Z under CIRCUIT TESTS in appropriate G - TEST W/CODES article.

1. Check For Diagnostic Trouble Codes (DTC)

Perform QUICK TEST in appropriate G - TEST W/CODES article. If DTCs are present, service DTCs. See appropriate CIRCUIT TEST under CIRCUIT TESTS in appropriate G - TEST W/CODES article. If DTCs are not present, go to next step.

2. Check Battery

Turn ignition on. Check battery voltage. If battery voltage is less than 12 volts, service battery as necessary and check charging system. If battery voltage is more than 12 volts, go to next step.

3. Check For Spark

Using Spark Tester (D81P-6666-A or D89P-6666-A), check for spark at each spark plug wire or coil while cranking. If spark is consistent at all spark plug wires, go to next step. If spark is not consistent, go to CIRCUIT TEST JD under CIRCUIT TESTS in appropriate G - TEST W/CODES article to test crankshaft position sensor.

4. Check Spark Plugs

Remove and inspect spark plugs. Replace plugs as necessary. If spark plugs are okay, testing is complete. If fault is still present, go to CIRCUIT TEST H under CIRCUIT TESTS in appropriate G - TEST W/CODES article. If vehicle has a no-start condition, go to CIRCUIT TEST A under CIRCUIT TESTS in appropriate G - TEST W/CODES article.

EMISSION SYSTEMS & SUB-SYSTEMS

EXHAUST CATALYST

NOTE: Perform CIRCUIT TEST HF under CIRCUIT TESTS in appropriate G - TEST W/CODES article.

10/4/2008

SYSTEM/COMPONENT TESTS - EEC-V -1996 Ford Mustang GT

Page 12 of 15

NOTE: On models equipped with Electronic Air Injection System (EAIR), go to CIRCUIT TEST HM, step 1) under CIRCUIT TESTS in appropriate G - TEST W/CODES article. On models equipped with mechanical secondary air injection system, go to CIRCUIT TEST HM, step 40) under CIRCUIT TESTS in appropriate G - TEST W/CODES article.

SECONDARY AIR INJECTION

EXHAUST GAS RECIRCULATION

EGR Valve

1.Ensure all vacuum hoses are correctly routed and securely attached. Replace any crimped or broken hoses. Ensure there is less than one in. Hg vacuum to EGR valve at idle with engine at normal operating temperature. 2.Install tachometer. Disconnect Idle Air Control (IAC) wiring harness connector. Remove and plug vacuum hose at EGR valve. Start engine and allow to idle in Neutral. Note idle speed. Using hand vacuum pump, slowly apply 5-10 in. Hg vacuum to EGR valve. When vacuum is fully applied, engine should do one or more of the following:

� � � Engine should stall.

� � � Idle speed should drop more than 100 RPM.

� � � Idle speed should return to normal when vacuum is released.

Service or replace EGR valve if engine does not stall or idle speed does not respond as specified. Reconnect IAC harness connector. Unplug and reconnect vacuum hose at EGR valve.

EGR Vacuum Regulator Solenoid

Turn ignition off. Disconnect EGR Vacuum Regulator (EVR) solenoid wiring harness connector. Measure resistance across EVR solenoid terminals. If resistance is not 26-40 ohms, replace EVR solenoid. For additional testing, go to CIRCUIT TEST HE under CIRCUIT TESTS in appropriate G - TEST W/CODES article.

FUEL EVAPORATION

Canister Purge Solenoid

Turn ignition off. Disconnect Canister Purge (CANP) solenoid wiring harness connector. Measure resistance between CANP solenoid terminals. If resistance is not 30-90 ohms, replace CANP solenoid. For additional testing, go to CIRCUIT TEST HW under CIRCUIT TESTS in appropriate G - TEST W/CODES article.

Canister Vent Solenoid

10/4/2008

SYSTEM/COMPONENT TESTS - EEC-V -1996 Ford Mustang GT

Page 13 of 15

Turn ignition off. Disconnect CV solenoid wiring harness connector. Measure resistance between CV solenoid terminals. If resistance is not 48-65 ohms, replace CV solenoid and repeat QUICK TEST. If resistance is 45-65 ohms, solenoid is okay. If fault is still present, go to CIRCUIT TEST HX in SELF-DIAGNOSTICS - EEC-V article.

EVAP Canister

There are no moving parts in canister. Check for loose, missing, cracked or broken connections and parts. Repair or replace as necessary. There should be no liquid in canister.

Purge Flow Sensor

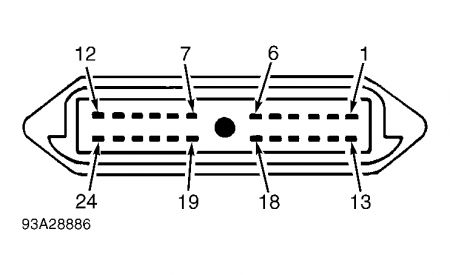

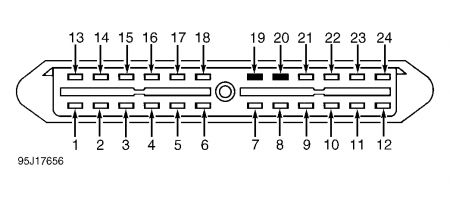

Turn ignition off. Disconnect Purge Flow (PF) sensor wiring harness connector. Allow sensor to cool to room temperature. Measure resistance between PFS SIG terminal and PWR GND terminal. See Fig. 2 . If resistance is less than 25.5 ohms, replace PF sensor. If resistance is 25.5 ohms or more, measure resistance between PFS SIG terminal and VPWR terminal. If resistance is not 25.65-28.35 ohms, replace PF sensor. If resistance is 25.65-28.35 ohms, measure resistance between PWR GND terminal and VPWR terminal. If resistance is more than 130 ohms, replace PF sensor. If resistance is 130 ohms or less, PF sensor is okay. If fault is still present, go to CIRCUIT TEST HW under CIRCUIT TESTS in appropriate G - TEST W/CODES article.

10/4/2008

SYSTEM/COMPONENT TESTS - EEC-V -1996 Ford Mustang GT

Page 14 of 15

Fig. 2: Identifying Purge Flow Sensor Connector Terminals

Canister Purge Valve/Vapor Management Valve

Turn ignition off. Disconnect Canister Purge Valve (CVP)/Vapor Management Valve (VMV) wiring harness connector. Using DVOM, measure resistance between CVP/VMV SIG and VPWR terminals. If resistance is not 30-36 ohms, replace CVP/VMV. If resistance is 30-36 ohms, sensor is okay. If fault is still present, go to CIRCUIT TEST HX under CIRCUIT TESTS in appropriate G - TEST W/CODES article.

POSITIVE CRANKCASE VENTILATION

1. Check Positive Crankcase Ventilation (PCV) Valve

Remove PCV valve. Shake valve and listen for rattle. If PCV valve rattles when shaken, go to

10/4/2008

SYSTEM/COMPONENT TESTS - EEC-V -1996 Ford Mustang GT

Page 15 of 15

next step. Replace PCV valve if it does not rattle when shaken.

2. Check PCV System

Start engine and warm to normal operating temperature. Disconnect hose from remote air cleaner or outlet tube. Place a stiff piece of paper over end of hose. If vacuum from hose does not hold paper in place for one minute, repair clogged or leaking hose as necessary. If vacuum from hose holds paper in place for one minute, PCV system is okay and testing is complete.

10/4/2008

Saturday, October 4th, 2008 AT 1:26 PM