Hello .. thanks for the donation .. much appreciated

Hope this helps ..let me know

Distributor

All engines are equipped with the EEC-IV ignition system with a distributor mounted TFI-IV module. No adjustments are required.

TEST D13 - SPARK TIMING

NOTE:Perform this test when Service Code 18 or 49 is displayed during QUICK TESTS or when directed here by other test procedures.

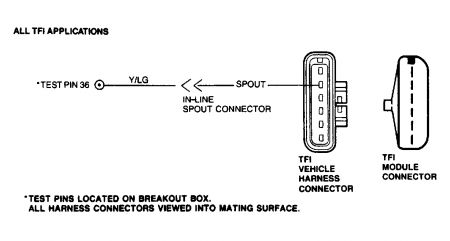

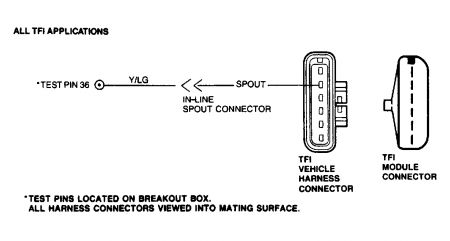

Fig. 47: Spark Timing Check Circuit

To prevent replacement of good components, be aware that the following non-EEC related areas may be at fault: engine condition (valves, vacuum leaks, valve timing, EGR valve, etc.), PIP sensor, and TFI ignition module. This test is intended to diagnose the SPOUT circuit in the harness, base timing and the ECA.

KOER Code 18: Check Computed Spark Timing. On TFI vehicles, Code 18 indicates SPOUT circuit is open. Possible causes for this fault are: open harness circuit or faulty ECA or TFI module. Perform KOER SELF-TEST and verify that SELF-TEST is activated. Check and record timing while in KOER SELF-TEST. System locks timing for a period of 2 minutes after last service code is displayed. Computed timing during these 2 minutes is equal to base timing plus 20 degrees (+/- 3 degrees). If computed timing is correct, go to KOER SELF-TEST. If timing is not to specification, go to next step.

Checking Base Timing. Locate Spark Output (SPOUT) connector and open the connection. Start engine and check for 10 degrees BTDC base timing +/- 3 degrees. If base timing is correct, go to next step. If base timing is incorrect, on TFI equipped vehicles adjust base timing as necessary. After timing is reset, reconnect SPOUT and perform COMPUTED TIMING CHECK.

Checking For Power to ECA. Turn key off and wait 10 seconds. Disconnect ECA 60-pin connector. Inspect connector for damaged pins, corrosion, or loose wires. Repair if necessary. Install breakout box. With KOEO, and DVOM set on 20-volt scale, measure voltage between test pins No. 37 and 40, and between test pins No. 57 and 60 at the breakout box. If either reading is less than 10.5 volts, go to TEST A2 - VEHICLE BATTERY , step 1). If both readings are 10.5 volts or more, go to next step.

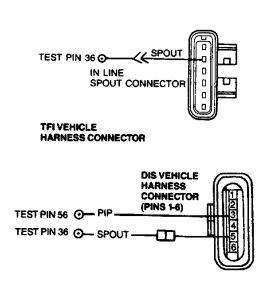

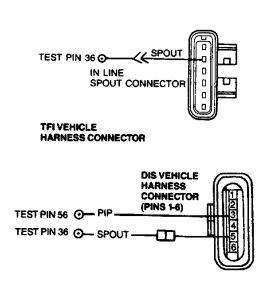

Checking SPOUT Circuit For Continuity. Turn key off and wait 10 seconds. Install breakout box. Disconnect ECA and TFI module. With DVOM set on 200-ohm scale, measure resistance between test pin No. 36 (SPOUT) at breakout box and SPOUT pin at TFI harness connector. See Fig. 48 . If reading is greater than 5 ohms, repair open circuit. Connect SPOUT connector and check timing as described in step 1). If reading is 5 ohms or less, go to next step.

Fig. 48: TFI Module Connector

Check SPOUT For Shorts. Turn key off and wait 10 seconds. Install breakout box and disconnect ECA. Set DVOM on 200K-ohms scale. Perform the following measurements:

Short To Ground. Measure resistance between test pin No. 36 and test pins No. 16, 20, 40, 46 and 60.

Short To Power. Measure resistance between test pin No. 36 and test pins No. 26,37 and 57.

Short to PIP Circuit. Measure resistance between test pin No. 36 and test pin No. 56.

If all resistances are greater than 10K ohms, go to next step. If resistances are not greater than 10K ohms, service short circuit. Remove breakout box, reconnect components and repeat QUICK TEST.

Checking ECA. Turn key off and wait 10 seconds. Install breakout box. Ensure ECA and TFI module are connected. Set breakout box timing switch to "DIST" position. Set DVOM on 20-volt scale. Measure voltage between test pin No. 36 at the breakout box and battery negative terminal during KOER SELF-TEST. If voltage is between 4 and 10 volts, EEC system is okay, remove breakout box and diagnose TFI ignition system. If voltage is not between 4 and 10 volts, remove breakout box, replace ECA and rerun QUICK TEST.

Continuous Memory Code 49: Check Harness Continuity. Code 49 indicates SPOUT signal has defaulted to 10 degrees BTDC. The SPOUT signal has a variable duty cycle with an amplitude of 4 volts to battery voltage (VBAT). If the SPOUT signal fails, the TFI module generates a fixed dwell and constant spark signal based on CID and PIP signals. This is the Failure Management Effects Mode (FMEM). Possible causes are: DIS module or faulty SPOUT signal circuit from ECA to DIS module. Turn key off and wait 10 seconds. Install breakout box and leave ECA disconnected. Disconnect DIS module. Set DVOM on 200-ohm scale. Measure resistance between test pin No. 36 at the breakout box and pin No. 5 at the DIS module connector. If resistance is less than 5 ohms, go to next step. If resistance is greater than 5 ohms, ensure SPOUT connector is okay. If okay, repair open circuit, reconnect all components and rerun QUICK TEST.

Check Spout Circuit For Short to Power or Ground. Turn key off and wait 10 seconds. Install breakout box. Disconnect ECA and DIS module. Set DVOM on 200K-ohm scale. Measure resistance between test pin No. 36 at the breakout box and test pins No. 16, 40 and battery positive. If all resistances are greater than 10K ohms, diagnose TFI or DIS ignition system. If resistances are less than 10K ohms, service SPOUT circuit for shorts. Reconnect all components and rerun QUICK TEST.

Tuesday, February 3rd, 2009 AT 8:05 PM