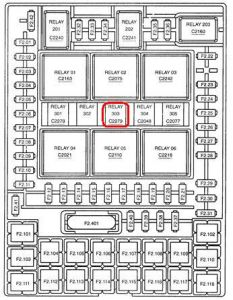

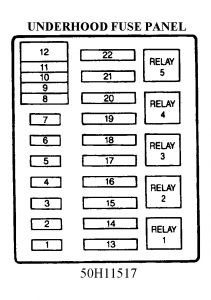

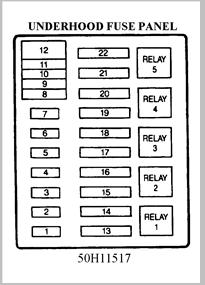

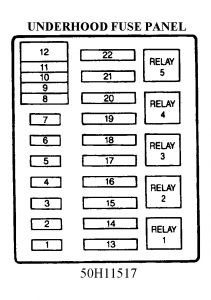

Fuel Pump Relay.....On engine bay fuse/relay block. relay # 2

Fuel Pump Actuation

When ignition switch is turned to START position, PCM operates fuel pump relay to provide fuel for starting engine. PCM senses engine speed and shuts off fuel pump by opening ground circuit to fuel pump relay when engine stops or speed drops to less than 120 RPM. When ignition switch is in ON position, EEC power relay is energized (contacts closed). Power is provided to fuel pump relay and timer in PCM. Fuel pump receives power through fuel pump relay contacts.

When dual tanks are used, each tank is equipped with a low pressure pump. Such a system has a total of 3 pumps: 2 low pressure and one high pressure.

High Pressure Fuel Pump

The high pressure fuel pump is positioned inside fuel tank. A reservoir is built onto pump and sender assembly.

In a 2-tank system, sender assembly handles switching of high pressure fuel through internal valves. Should one tank overfill during use (return line returns fuel to wrong tank), pump and sender unit in overfilling tank need replacement.

The high pressure fuel pump is capable of pumping over 33 gallons (125L) of fuel per hour at a working pressure of 39.2 psi (2.75 kg/cm2 ). This pump also has internal pressure relief and discharge check valves.

Mechanical Selector Valve

A driver-operated selector switch controls selector valve for switching fuel supply from one tank to another. This valve switches fuel supply and return lines from one tank to another in response to fuel pressure from in-tank pumps acting on its actuating diaphragm.

The diaphragm switches tank connection when less than 2 psi of fuel pressure is acting on upper side of front tank and lower side of rear tank. Valve function depends upon proper operation of in-tank low pressure pumps. In all dual-tank vehicles, excess fuel not used by engine is returned to same tank from which it was pumped.*****

Saturday, May 29th, 2021 AT 11:04 AM

(Merged)