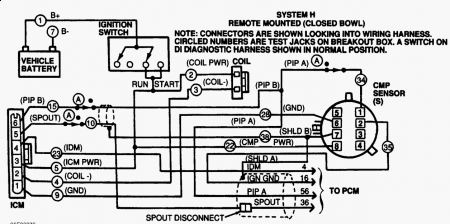

Which 6 do you have 4.0 or 4.9? Distributorless? If so Remove the EI Module(IGNITION) take it to the parts store they can test it there, also have you tried to read the codes? Try this as a next step:

http://www.2carpros.com/trouble_codes/obd1_trouble_codes/ford_lincoln_mercury_codes.htm

Go to this link for reading codes.

Test the crank sensor with an OHM meter, unplug the sensor, measure across the sensor terminals, reading should be 210-250 ohms, if not replace it. I need to know if yours has a distributor or not? Also did you check the fuel pressure at the fuel rail?

http://www.2carpros.com/car_repair_video/test_fuel_injection_pressure.htm

Go here and checkout our video.

And you do have spark at all plugs right?

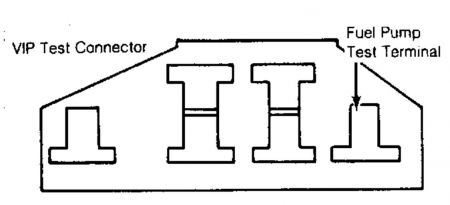

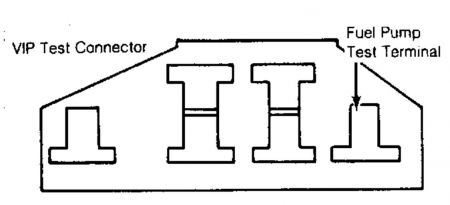

Test your pressure at rail as in the video, test tank pumps like this: In-Tank Reservoir (ITR) Fuel Pump Testing 1. Ensure fuel tank has adequate fuel. Turn ignition off. Install fuel pressure gauge. Install a test lead to Fuel Pump (FP) lead of VIP test connector. See Fig. 9 . Turn ignition on, engine off. Ground test lead to run fuel pump. Check fuel pressure. See FUEL PRESSURE SPECIFICATIONS . If fuel pressure is within specification, go to step 5). If fuel pressure is not within specification, go to next step. 2. If pressure is low, but greater than 3 PSI (21 kPa), go to next step. If pressure is not more than 3 PSI (21 kPa) go to step 4). 3. Check fuel system for: Ã Â Â Plugged fuel filter (replace filter and check again for proper pressure). Ã Â Â Kinked/restricted fuel lines (visual inspection). Ã Â Â Low voltage to fuel pump (should be within 0.5 volt of battery voltage at connector). Ã Â Â Disconnect return fuel line and note if fuel is being returned during this low pressure condition. If fuel is being returned, replace or adjust pressure regulator. If a problem was found, repair as necessary. After repair, go to step 1) and retest system. If a problem was not found, replace fuel pump and go to step 1) and retest system. 4. Check the following electrical circuit problems: Ã Â Â Ensure inertia switch is not open (reset switch as required). Ã Â Â Wiring at fuel pump/tank connector loose or open. Ã Â Â Fuel pump ground connection at chassis loose or defective. Ã Â Â Improper fuel pump relay operation (should operate when fuel pump test lead is grounded with the ignition key on). Ã Â Â EEC relay not operating if fuel pump relay doesn't operate. If a problem was found, repair as necessary. After repair, go to step 1) and retest system. If a problem was not found, replace fuel pump and go to step 1) and retest system. 5. Remove ground from test lead and note pressure on gauge. Pressure should remain within 2 PSI (14 kPa) for 3 minutes after lead is ungrounded. If pressure holds as specified, go to step 7). If pressure does not hold as specified, go to next step. 6. Check fuel lines and connectors for leakage. Disconnect fuel return line and plug engine side. Momentarily activate fuel pump by grounding test lead. Raise pressure to approximate operating pressure and repeat step 5). If pressure holds, replace pressure regulator and repeat step 5). If pressure decays rapidly, go to next step. If system still fails step 5), there may be a leaking fuel injector or rail. Repair as necessary and go to step 5). 7. If pressure decays rapidly enough that needle movement can be observed, replace ITR unit if equipped with a single tank. If equipped with dual tanks, go to next step. If pressure holds, go to step 10). 8. Remove fuel supply line from sender port of midship tank. Change pressure gauge from 5/16" to 3/8" adaptor to fit fuel line quick connector. Connect gauge to end of supply line removed from midship sender. Move the tank selector switch to REAR tank position. Turn ignition on and hold until fuel pump shuts itself off (approximately one second). Turn ignition off. Observe pressure gauge. If pressure holds steady, go to next step. If pressure does not hold steady, replace rear ITR unit and go to next step. 9. Remove fuel pressure gauge from supply line. Install a 3/8" right-angle quick-connector to pressure gauge. Connect gauge to midship tank ITR supply port. Move the tank selector switch to the FRONT tank position. Turn ignition to on position and hold until fuel pump shuts itself off (approximately one second). Turn ignition off. Observe pressure gauge. If pressure holds steady, midship ITR unit is okay. Remove fuel pressure gauge and reconnect all fuel lines. Go to step 1) to retest system. If pressure does not hold steady, replace midship ITR unit. Go to step 1 to retest system. 10. Disconnect and plug vacuum line connected to the pressure regulator. Start engine and run at idle. Check fuel pressure. See FUEL PRESSURE SPECIFICATIONS . If fuel pressure is within specification, go to step 12). If fuel pressure is not within specification, go to next step. 11. Check the following for cause of low pressure: Ã Â Â Fuel filter restriction. Ã Â Â Improper fuel regulator adjustment. Ã Â Â Fuel line restricted. Ã Â Â Improper voltage to fuel pump (battery voltage at pump connections). If a problem was found, repair as necessary. After repair, go to step 1) and retest system. If a problem was not found, replace fuel pump and go to step 1) and retest system. 12. With engine running at idle and vacuum line disconnected, note fuel rail pressure. Rapidly accelerate engine and watch fuel pressure. If pressure remains within 5 PSI of starting pressure, system is okay. If pressure does not remain within 5 PSI of starting pressure, go to step 11). FUEL PRESSURE REGULATOR 1. Relieve fuel pressure. See FUEL SYSTEM PRESSURE RELEASE . Connect fuel pressure gauge at Schrader valve. Start and operate engine for 10 seconds. Stop engine for 10 seconds. Start and operate engine for 10 seconds. Stop engine and remove pressure regulator vacuum hose. Check for fuel at vacuum port. 2. If fuel is present, replace fuel pressure regulator. If fuel is not present, start and operate engine for 30 seconds. Stop engine and check fuel pressure gauge. If gauge reading drops more than 5 psi (.35 kg/cm 2 ) in 60 seconds, disconnect and plug fuel return line at engine. Start and operate engine until normal fuel pressure is obtained. 3. Stop engine and check fuel pressure gauge. If gauge reading drops more than 5 psi (.35 kg/cm 2 ) in 30 seconds, replace high pressure fuel pump (dual pump system) or fuel sender/pump assembly (single pump type). If gauge does not drop more than 5 psi (.35 kg/cm 2 ) in 30 seconds, replace NOTE: Road testing vehicle while monitoring pressure may give a better test under load conditions. NOTE: For fuel pressure specifications, see FUEL PRESSURE SPECIFICATIONS article.

Tuesday, August 24th, 2010 AT 4:17 PM